A kind of preparation technology of whole body brick with single fabric layer and its whole body brick

A preparation process and fabric layer technology, applied in the field of architectural ceramics, can solve the problems of difficult control of pattern and texture, high temperature resistance of fabrics, and many single-burning defects, and achieve the effects of good plasticity, high refractoriness, and strong three-dimensional layering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

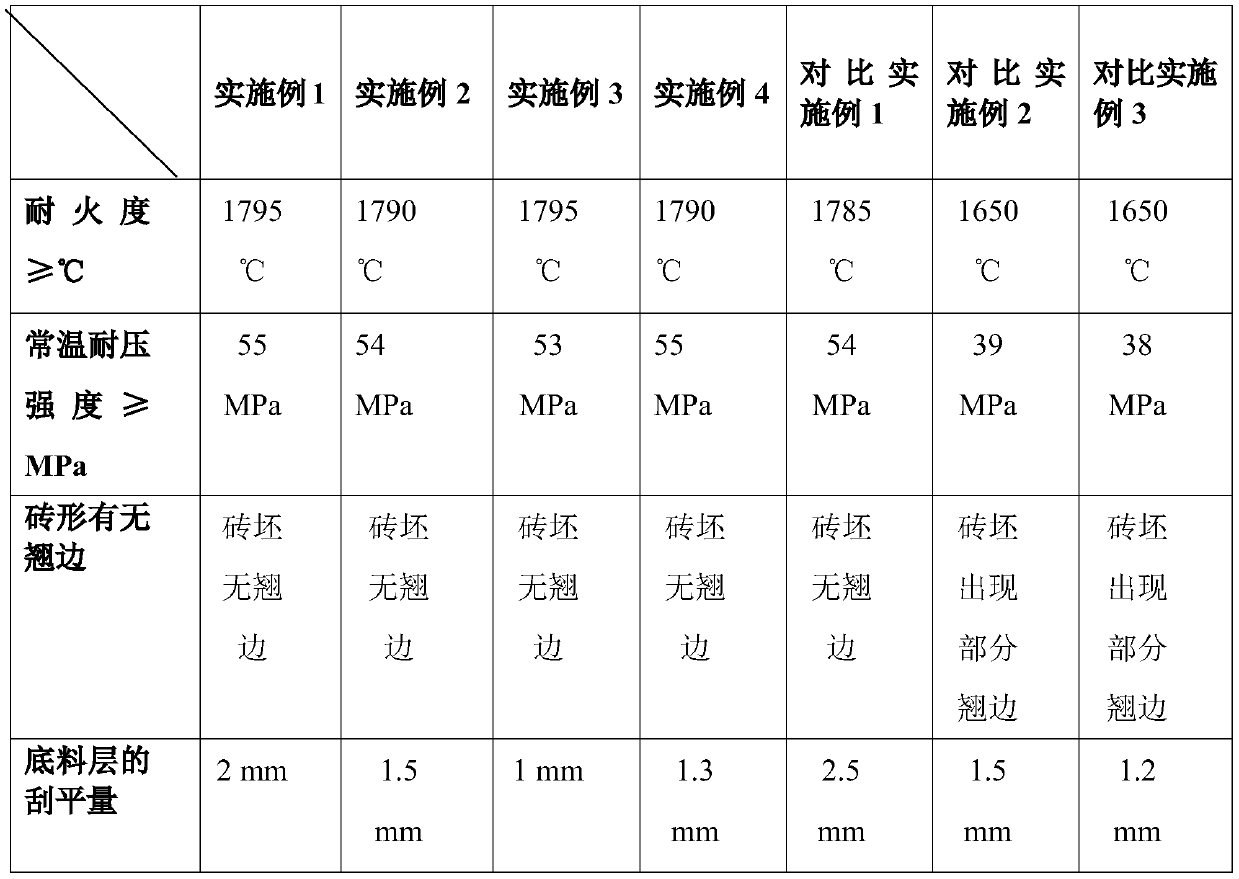

Embodiment 1

[0030] Embodiment 1-a kind of preparation technology of the whole body brick of single face layer, comprises the steps:

[0031] (1) The adobe base material containing 25% by weight of the high-alumina mud material is applied in the die cavity of the press using a grid to form a base material layer;

[0032] Among them, the moisture content of the brick bottom material is controlled at 6.75%, and its particle size is controlled at 93% for 100-mesh sieve. %, the remainder of each mesh is the cumulative value;

[0033] (2) Use a multi-tube fabric system to distribute patterned fabrics on the bottom material layer to form a fabric layer;

[0034]Among them, the particle size of the patterned fabric is controlled to be less than 1% of the 20-mesh sieve, 34-49% of the 40-mesh sieve, 80-92% of the 60-mesh sieve, and more than 95% of the 100-mesh sieve. value;

[0035] (3) Pressing to form a brick, and the thickness of the bottom material layer accounts for 10% of the thickness of...

Embodiment 2

[0037] Embodiment 2-a kind of preparation technology of the whole body brick of single face layer, comprises the steps:

[0038] (1) The brick base material containing 40% by weight of high-alumina mud material is applied to the die cavity of the press using a grid to form a base material layer;

[0039] Among them, the moisture content of the brick bottom material is controlled at 7.45%, and the particle size is controlled at 20 mesh sieve residue 93% %, the sieve remainder of each mesh is the cumulative value;

[0040] (2) Using a multi-tube cloth system to distribute patterned fabrics on the bottom material layer to form a fabric layer;

[0041] Among them, the particle size of the patterned fabric is controlled to be less than 1% of the 20-mesh sieve, 34-49% of the 40-mesh sieve, 80-92% of the 60-mesh sieve, and more than 95% of the 100-mesh sieve. value;

[0042] (3) Pressing to form a brick, and the thickness of the bottom material layer accounts for 20% of the thick...

Embodiment 3

[0045] Embodiment 3-a kind of preparation technology of the whole body brick of single face layer, comprises the steps:

[0046] (1) The brick base material containing 35% by weight of high-alumina mud material is applied to the die cavity of the press using a grid to form a base material layer;

[0047] Among them, the moisture content of the brick bottom material is controlled at 7.05%, and the particle size is controlled at 20 mesh sieve residue 93% %, the sieve remainder of each mesh is the cumulative value;

[0048] (2) First, the particle size is 20-mesh sieve residue 95%, and the sieve residue of each mesh is the cumulative value The patterned fabric is subjected to a secondary refinement process, that is, the patterned fabric is ground into fine powder again, and its particle size is 20%-60% of the 100-mesh sieve, and then a multi-tube cloth system is used to distribute the pattern on the bottom material layer. fabric to form a fabric layer;

[0049] (3) Pressing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com