Pneumatic type ball screw prestretching device

A ball screw and pre-stretching technology, which is applied to feeding devices, metal processing machinery parts, maintenance and safety accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

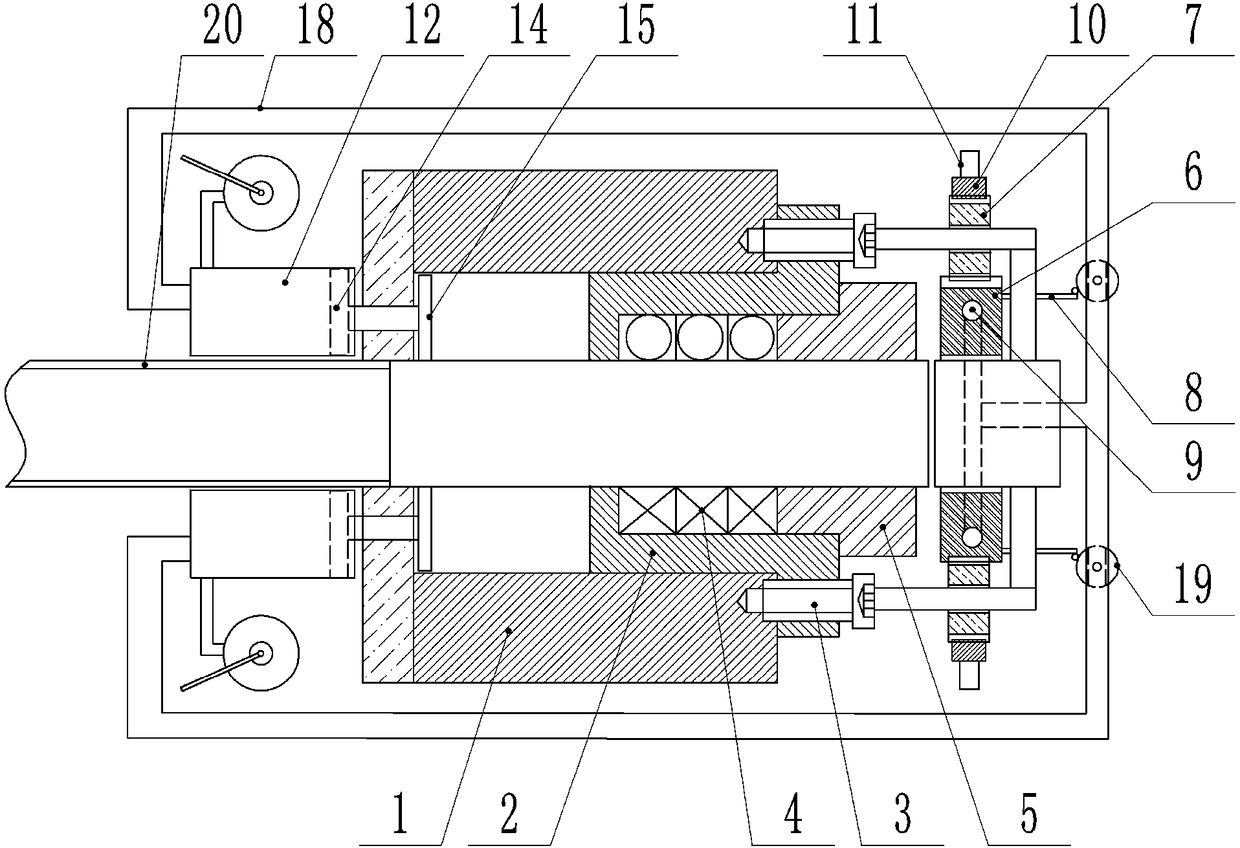

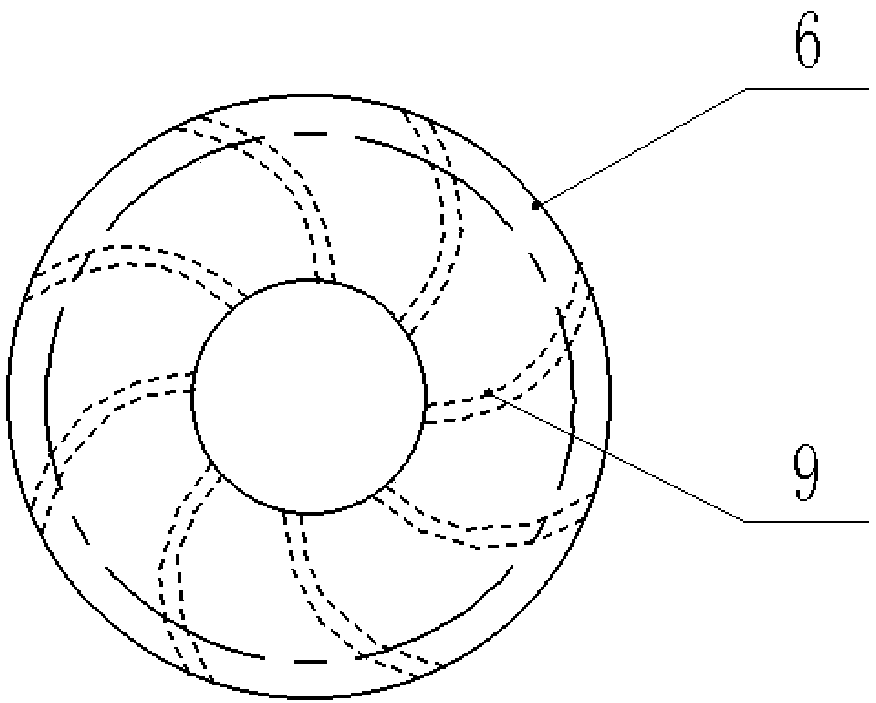

[0019] The reference signs in the drawings of the specification include: seat body 1, sleeve 2, adjusting bolt 3, bearing 4, compression sleeve 5, central gear 6, side gear 7, shift lever 8, exhaust duct 9, inner ring gear 10. Protrusion 11, first cylinder body 12, second cylinder body 13, top plate 14, extrusion plate 15, pressure one-way air inlet pipe 16, pressure one-way air outlet pipe 17, exhaust pipe 18, ball 19, lead screw 20, pendulum 21.

[0020] Example figure 1 Shown: Pneumatic ball screw pre-tensioning device, including mounting base, synchronous adjustment mechanism and pressure adjustment mechanism.

[0021] The mounting seat includes a cylindrical seat body 1, a sleeve 2 is sleeved inside the seat body 1, and an adjusting bolt 3 threaded with a thread is threaded between the sleeve 2 and the seat body 1. There are four adjusting bolts 3 in total. A bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com