Calculation method capable of predicting oxygen-free copper electron beam welding parameters

A technology of electron beam welding and calculation method, which is applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of troublesome welding parameter determination, affecting the quality of oxygen-free copper weld formation, etc., and it is simple to meet the judgment standard The effect of clear, shortened process test time, accurate and effective welding parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

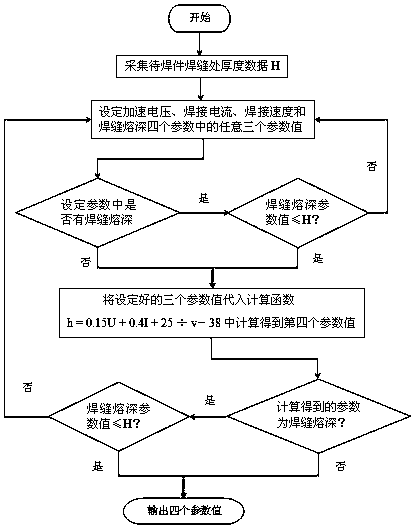

Method used

Image

Examples

example 1

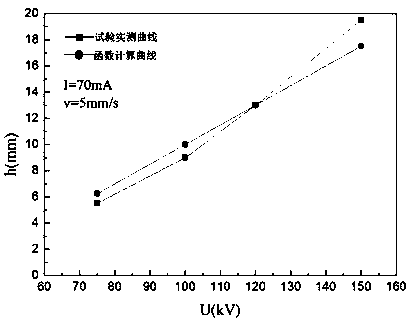

[0045]Take 8 pieces of TU1 oxygen-free copper with a length of 50mm, a width of 20mm, and a thickness of 42mm to carry out two-to-two butt electron beam welding tests respectively. There are four sets of tests in total. The length of the weld is 50mm, and no backing plate is added to the back of the weld. The seam thickness H is 42 mm.

[0046] Set the acceleration voltage U of the four groups of tests as U 1 =75 kV, U 2 =100 kV, U 3 =120 kV, U 4 =150kV.

[0047] The welding speed v of the four groups of experiments is set to be 5mm / s.

[0048] The welding current I of the four groups of experiments is set to be 70mA.

[0049] The acceleration voltage U, welding speed v and welding current I set above are respectively obtained by using the oxygen-free copper electron beam welding parameter prediction calculation method:

[0050] h 1 =6.25mm, h 2 =10mm, h 3 =13mm, h 4 =17.5mm

[0051] The four sets of welding parameters determined above are used respectively:

...

example 2

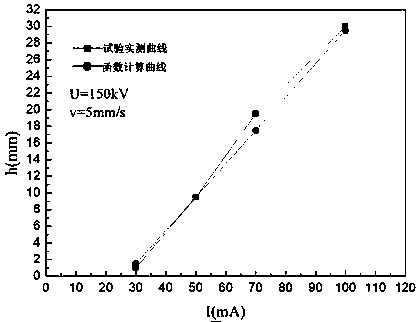

[0058] Take 8 pieces of TU1 oxygen-free copper with a length of 50mm, a width of 20mm, and a thickness of 42mm to carry out two-to-two butt electron beam welding tests respectively. There are four sets of tests in total. The length of the weld is 50mm, and no backing plate is added to the back of the weld. The seam thickness H is 42mm.

[0059] Set the welding current I of the four groups of experiments as I 1 =30mA, I 2 =50mA, I 3 =70mA, I 4 =100mA.

[0060] The welding speed v of the four groups of experiments is set to be 5mm / s.

[0061] The acceleration voltage U of the four groups of tests is set to be 150kV.

[0062] The acceleration voltage U, welding speed v and welding current I set above are respectively obtained by using the oxygen-free copper electron beam welding parameter prediction calculation method:

[0063] h 1 =1.5mm, h 2 =9.5mm, h 3 =17.5mm, h 4 =29.5mm

[0064] The four sets of welding parameters determined above are used respectively:

[0065]...

example 3

[0071] Take 8 pieces of TU1 oxygen-free copper with a length of 50mm, a width of 20mm, and a thickness of 42mm to carry out two-to-two butt electron beam welding tests respectively. There are four sets of tests in total. The length of the weld is 50mm, and no backing plate is added to the back of the weld. The seam thickness H is 42mm.

[0072] Set the welding speed v of the four groups of experiments as v 1 =2.5mm / s, v 2 =5mm / s, v 3 =7mm / s, v 4 =15mm / s.

[0073] Set the welding current I=70mA for four groups of experiments.

[0074] Set the acceleration voltage U=150kV for the four groups of tests.

[0075] The acceleration voltage U, welding speed v and welding current I set above are respectively obtained by using the oxygen-free copper electron beam welding parameter prediction calculation method:

[0076] h 1 =22.5mm, h 2 =17.5mm, h 3 =16.07mm, h 4 =14.17mm

[0077] The four sets of welding parameters determined above are used respectively:

[0078] U =150kV, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com