Feeding assembly of stone crusher

A crusher and component technology, applied in the field of building materials processing, can solve the problems affecting the service life of equipment, the production cost of material processing quality manufacturers, affecting the service life of equipment, increasing production costs, etc., to achieve guaranteed service life, easy control, and moving speed uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

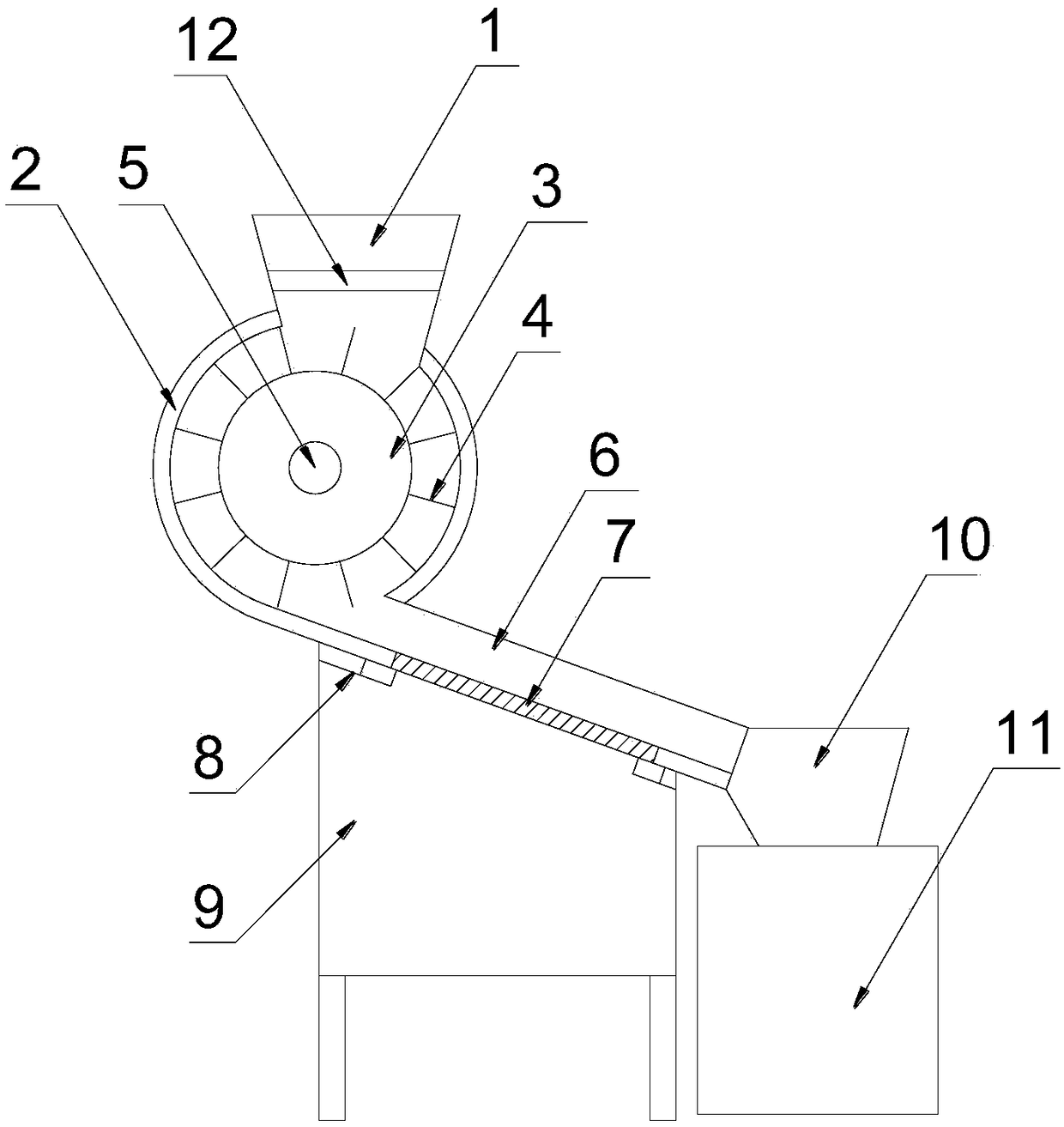

[0019] like figure 1 as shown, figure 1 It is a schematic structural diagram of a stone crusher feeding assembly proposed by the present invention.

[0020] refer to figure 1 , a kind of stone crusher feed assembly that the present invention proposes, comprises the first feed hopper 1, annular feed bin 2, feed roller 3, push plate 4, discharge plate 6, vibrating screen 7, recovery box 9 , the second feed hopper 10 and the crushing assembly 11;

[0021] The first feeding hopper 1 is fixed on the top of the annular feeding bin 2, and its discharge port communicates with the feeding port of the annular feeding bin 2; a magnetic ring 12 is fixedly installed on the outside of the first feeding hopper 1, and the magnetic ring 12 is located The middle part of feed hopper 1;

[0022] A rotating shaft 5 is set in the middle of the annular feed bin 2, and the rotating shaft 5 drives the feed roller 3 to rotate counterclockwise; the outer periphery of the feed roller 3 is evenly dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com