Inner surface hydrophilic modified hollow fiber membrane and its preparation method and application

A hydrophilic modification, fiber membrane technology, applied in the field of membrane science, can solve problems such as cumbersome steps, and achieve the effects of simple operation, self-cleaning, and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

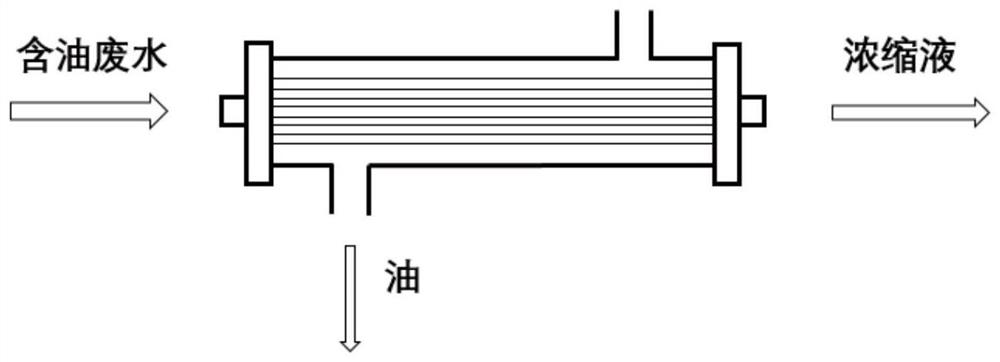

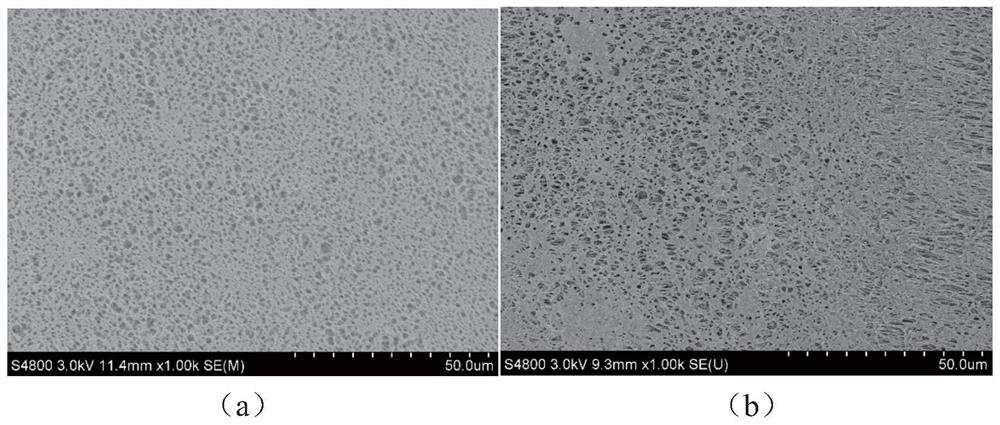

[0052] (1) A polypropylene (PP) hollow fiber membrane (purchased from Germany MEMBRANA company, model PP S6 / 2) with an average pore size of 0.2-0.3 μm, an inner diameter of 1800 μm, and a film thickness of 450 μm was used as the base membrane, according to figure 1 , making 200 base membranes into hollow fiber membrane modules;

[0053] Use absolute ethanol to infiltrate the hollow fiber membrane in the module: inject ethanol into the tube side of the hollow fiber membrane module through the pump, and circulate for 20 minutes;

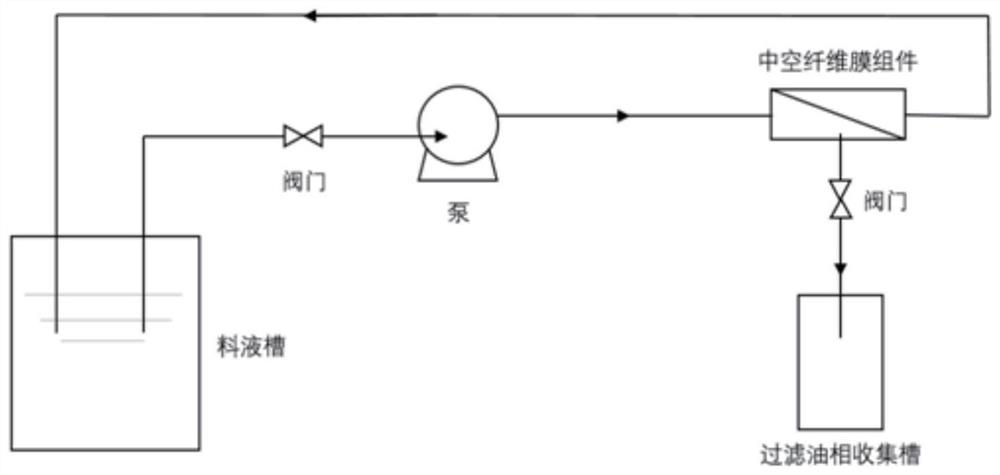

[0054] (2) Put the infiltrated hollow fiber membrane module into the circulating flow device with the pump as the core (such as figure 2 shown), add 100mg copper sulfate pentahydrate, 160mg dopamine hydrochloride, 160mg polydiallyldimethyl Ammonium chloride (PDDA, 200000Da) and 160 μL of hydrogen peroxide were prepared into a reaction solution, which was circulated in the tube side of the hollow fiber membrane for 30 minutes;

[0055] After the reac...

Embodiment 2~9

[0058] Regulate the add-on of dopamine hydrochloride and PDDA, make the concentration of dopamine hydrochloride and PDDA in the reaction solution respectively as shown in table 1, other conditions are the same as embodiment 1.

[0059] The surface hydrophilization modified hollow fiber membranes prepared in Examples 1 to 9 were tested for performance. The test items were the water contact angle on the inner surface of the hollow fiber membrane, the oil contact angle on the inner surface, the oil flux and the water retention rate, and the results As shown in Table 1.

[0060] Table 1 The performance test results of the surface hydrophilized modified hollow fiber membranes prepared in Examples 1 to 9

[0061]

[0062] From the test data in Table 1, it can be known that the change of dopamine concentration and polydiallyldimethylammonium chloride (PDDA) concentration has a great influence on various properties of the hollow fiber membrane.

Embodiment 10~13

[0064] In Examples 10 to 13, the reaction time of the reaction solution in the tube side of the hollow fiber membrane was adjusted to 45 min, 60 min, 75 min and 90 min, and other conditions were the same as in Example 1.

[0065] Performance tests were performed on the hollow fiber membranes prepared in Example 1 and Examples 10-13 with the inner surface hydrophilized modification, and the test results are shown in Table 2.

[0066] Table 2 Performance Test Results of the Surface Hydrophilic Modified Hollow Fiber Membrane Prepared in Example 1 and Examples 10-13

[0067]

[0068] From the test data in Table 2, it can be seen that with the increase of the reaction time, the hydrophilicity of the inner wall of the hollow fiber membrane increases, while the oil flux and retention rate show a downward trend.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com