Automatic shoe washing equipment with soaking-free function

A non-immersion and automatic technology, applied in the field of washing utensils, can solve the problems of large water consumption, large demand for water resources, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

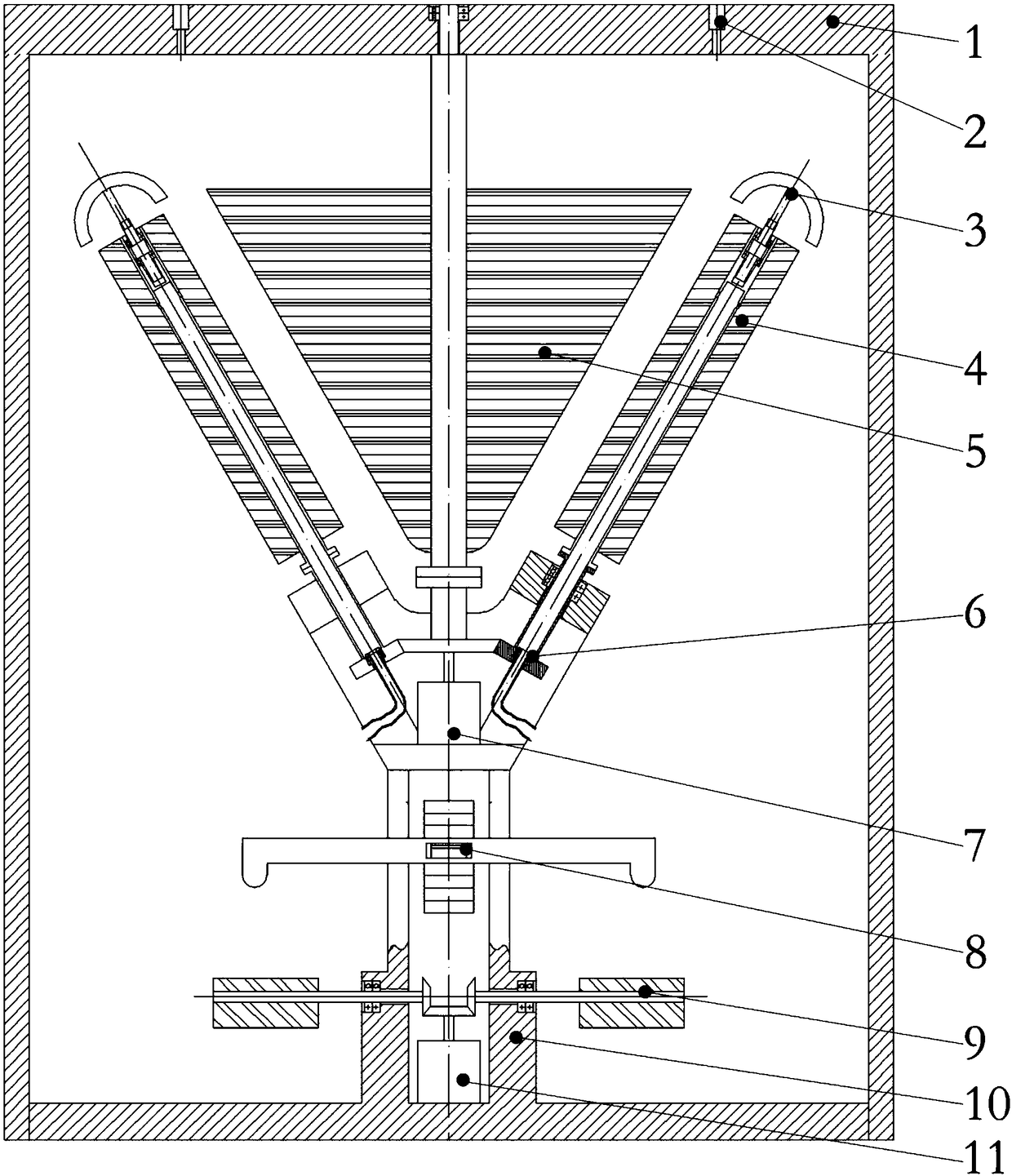

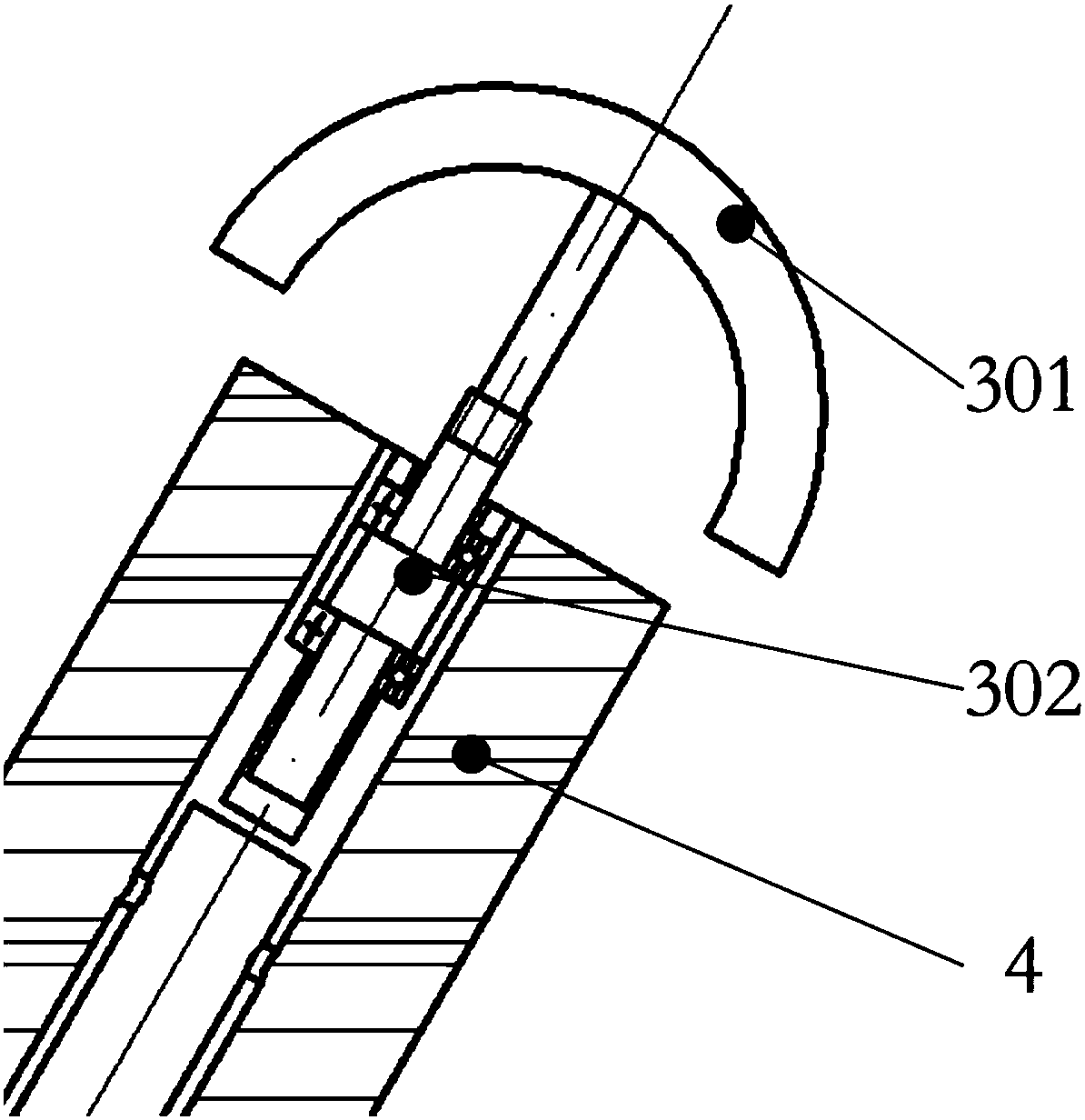

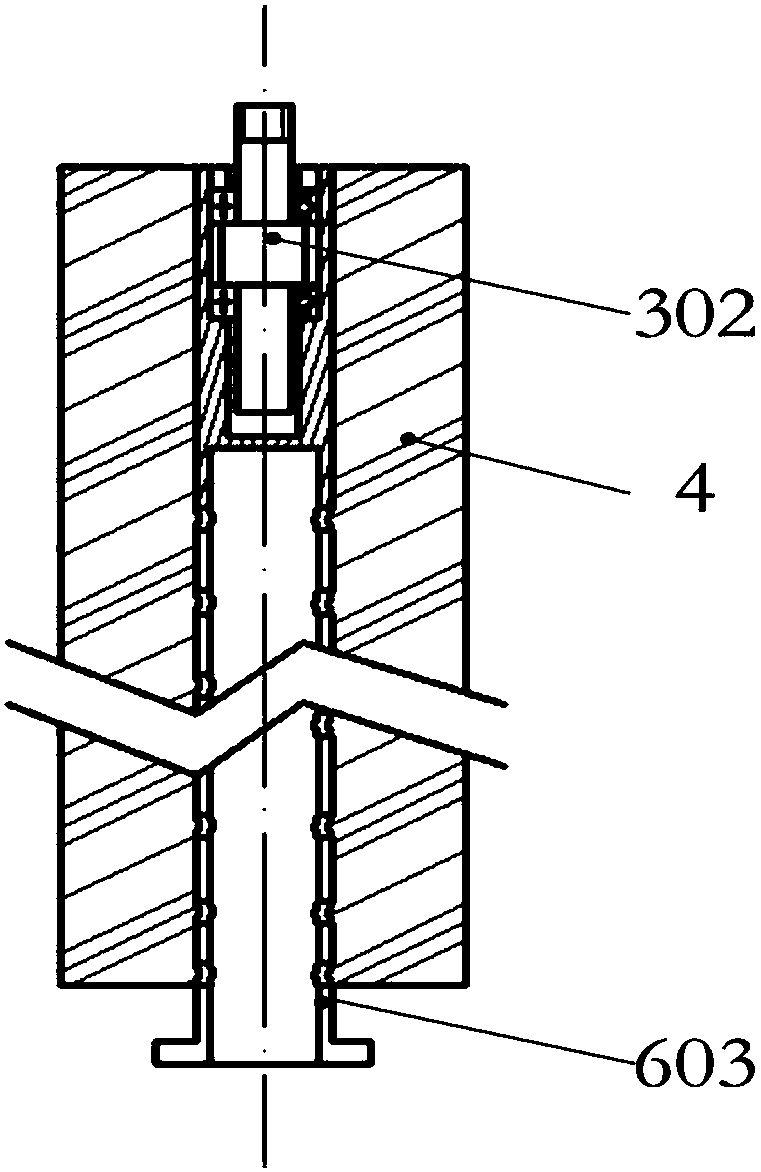

[0026] The schematic diagram of the overall structure of the soak-free automatic shoe washing equipment of the present invention is as follows: figure 1 As shown, it mainly includes an upper box body 1, a supporting device, a cleaning device, a spraying device, and a transmission device. The supporting device mainly includes the upper top plate 3 and the lower pinch plate 8; the cleaning device mainly includes the outer brush 5, the inner brush 4 and the bottom brush 9; the spraying device mainly includes the upper spraying device 2 and the inner spraying device 6; the transmission The device mainly includes motors 7,11.

[0027] Upper sprinkler 2 such as figure 1 As shown, it mainly means that a certain number of spray holes are set on the box body 1 of the cleaning equipment, and the washing solvent can be sprayed downward through the spray holes, so as to provide conditions for the outer brush 5 to clean the shoe upper. At the same time, the upper box body 1 is connected ...

Embodiment 2

[0033] When in use, insert the shoe bore into the inner brush, hang the shoe on the upper top plate, and adjust the movable gusset on the lower gusset to make the shoe produce a certain tension and complete the support for the shoe; when washing, spray the upper The shower device sprays out the washing solvent in advance to produce a certain wetting effect on the upper, and then the motor rotates, and the inner spray device squeezes out the washing solvent through the inner spray pipe with the rotation of the spray pipe, and at the same time, the rotation of the motor drives the inner The brushes on the outer, outer and bottom side are rotated to clean the inside of the shoe, the upper and the heel of the shoe respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com