A kind of preparation method of noodle with strong taste

A production method and strong technology, applied in the field of food processing, can solve problems such as large differences in the process of glutinous noodles, and achieve the effects of improving the taste, optimizing the efficiency, and ensuring food safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

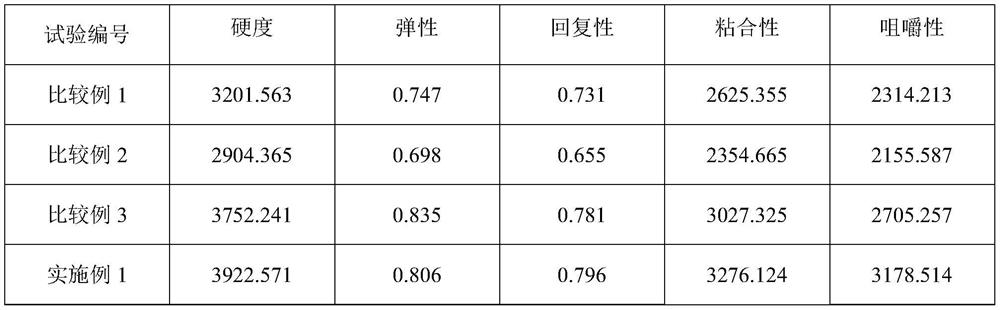

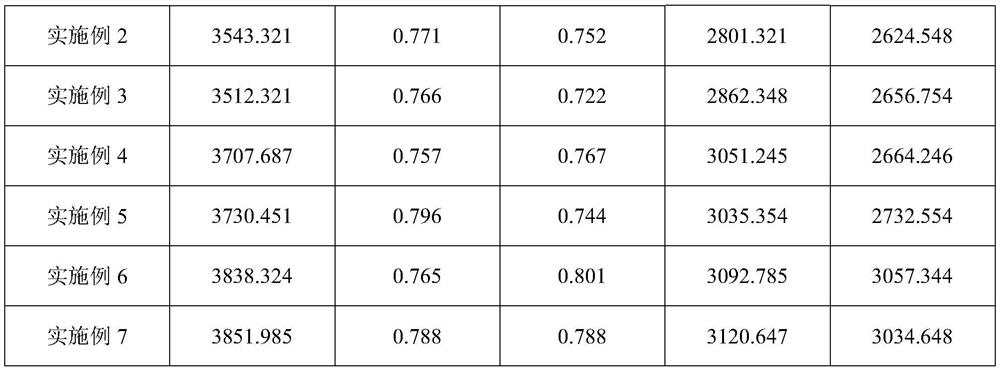

Examples

Embodiment 1

[0038] A method for making noodles with strong mouthfeel, comprising the steps of:

[0039] (1) Kneading dough: prepare salt solution, adjust its pH to 9.0, mix and stir the salt solution and flour according to the ratio of 1:3, and knead into dough;

[0040] (2) Noodles: put the dough in an environment with a relative humidity of 80%, first set the protein refolding temperature at 8°C and let it stand for 10 minutes, then set the protein water absorption expansion temperature at 36°C and let it stand for 20 minutes;

[0041] (3) The dough is compounded and rolled into a dough strip;

[0042] (4) Secondary noodles with noodles: place the noodles in an environment with a temperature of 14°C and a relative humidity of 80% for 15 minutes;

[0043] (5) After being cut into strips, dried and cooled, the noodles with strong mouthfeel are obtained.

Embodiment 2

[0045] A method for making noodles with a strong mouthfeel. In the step (2), first set the protein refolding temperature at 5° C. and let it stand for 10 minutes, and then set the protein water absorption expansion temperature at 33° C. and let it stand for 20 minutes. Others are with embodiment 1.

Embodiment 3

[0047] A method for making noodles with a strong mouthfeel. In the step (2), the protein refolding temperature is first set to 10° C. and left to stand for 10 minutes, and then the water absorption swelling temperature of the protein is set to 39° C. and then left to stand for 20 minutes. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com