A growing device for large-aperture Cz monocrystal and a growing method thereof

A growth method and a technology of a growth device, which are applied in the field of single crystal growth devices, can solve problems such as rising costs, and achieve the effect of eliminating growth and inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

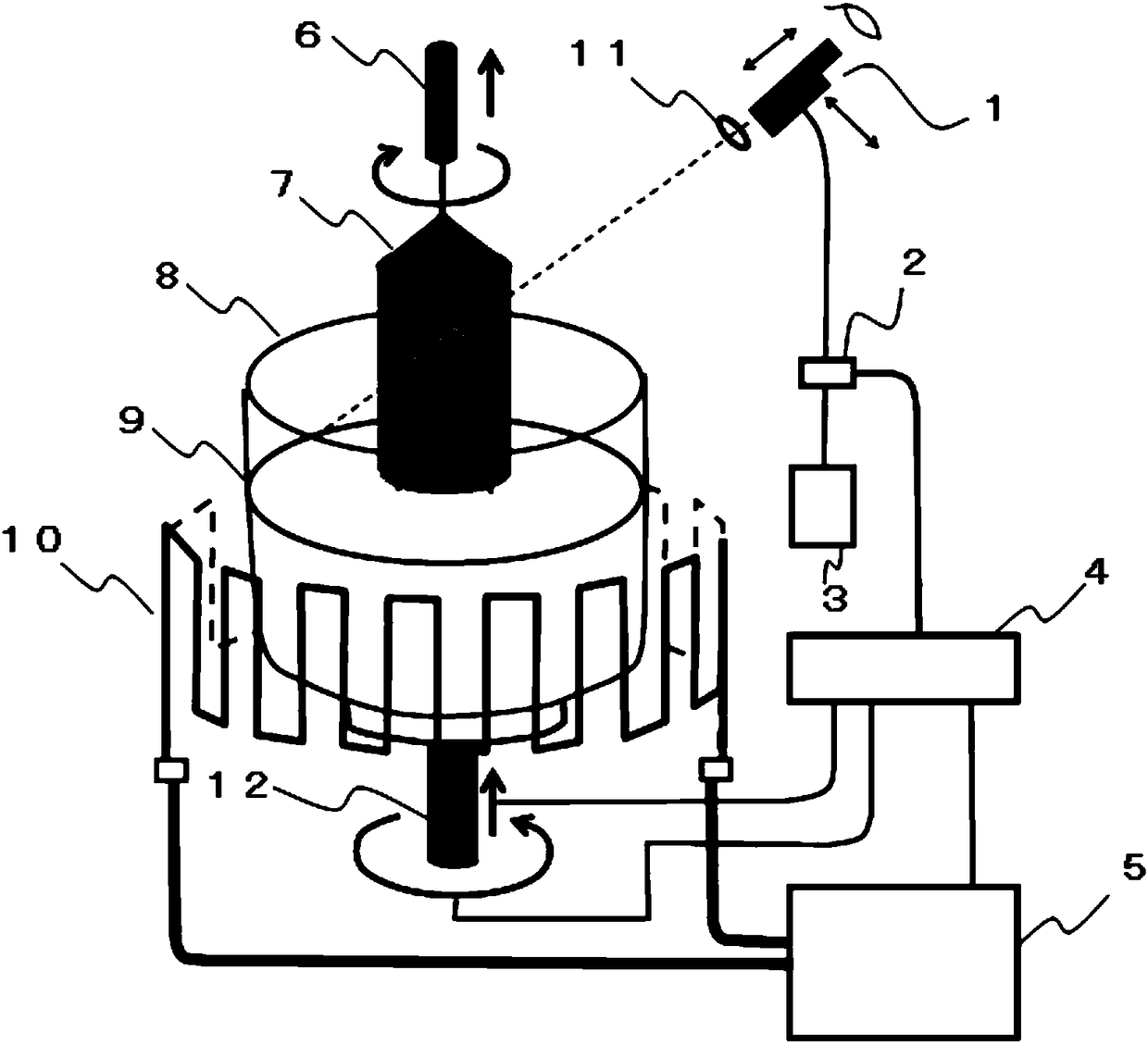

[0056] figure 1 1 is a schematic diagram of an embodiment of the device of the present invention, 1 is a temperature sensor, 2 is a conversion unit that converts the amount of light obtained from the temperature sensor into an electrical signal, and 4 is a control unit for crystal growth. In addition, 11 is the observation window of the crystal growth furnace, through which the aiming of the sensor 1 can obtain the boundary portion 9 where the inner surface of the quartz crucible 8 and the molten liquid 13 are inscribed, and 7 is the temperature obtained during the crystal growth period of the boundary portion 9 Changes in the temperature detection mechanism.

[0057] In addition, the light quantity acquired by the optical system sensor part of the temperature sensor 1 is guided through the optical fiber to the converter 2, and reaches the indicator through the converter 2 that converts the light quantity into an electrical signal corresponding to temperature. In addition to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com