High-performance thimble seat housing

A bushing seat, high-performance technology, applied in the direction of the substation/distribution device casing, etc., can solve the problems of sharp welding seam, discharge, etc., and achieve the effect of ensuring welding quality and facilitating assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below based on the drawings and the embodiments.

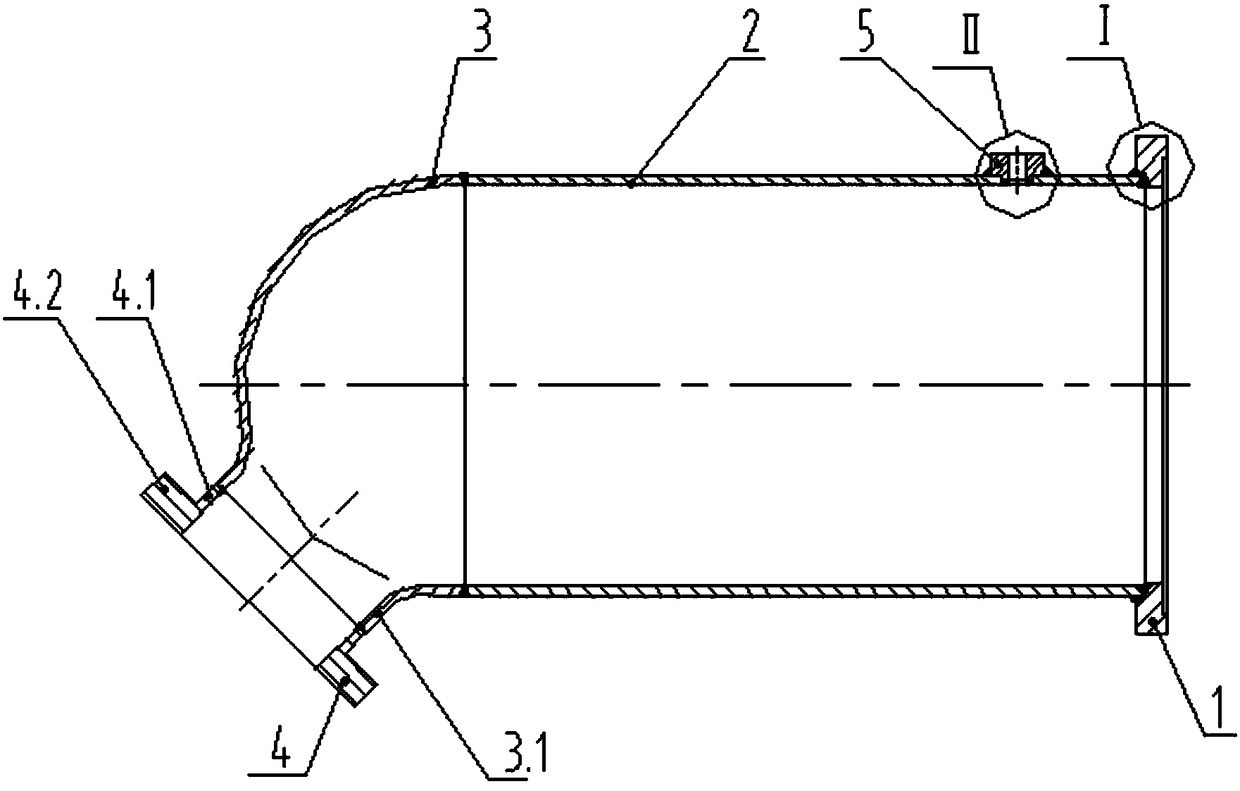

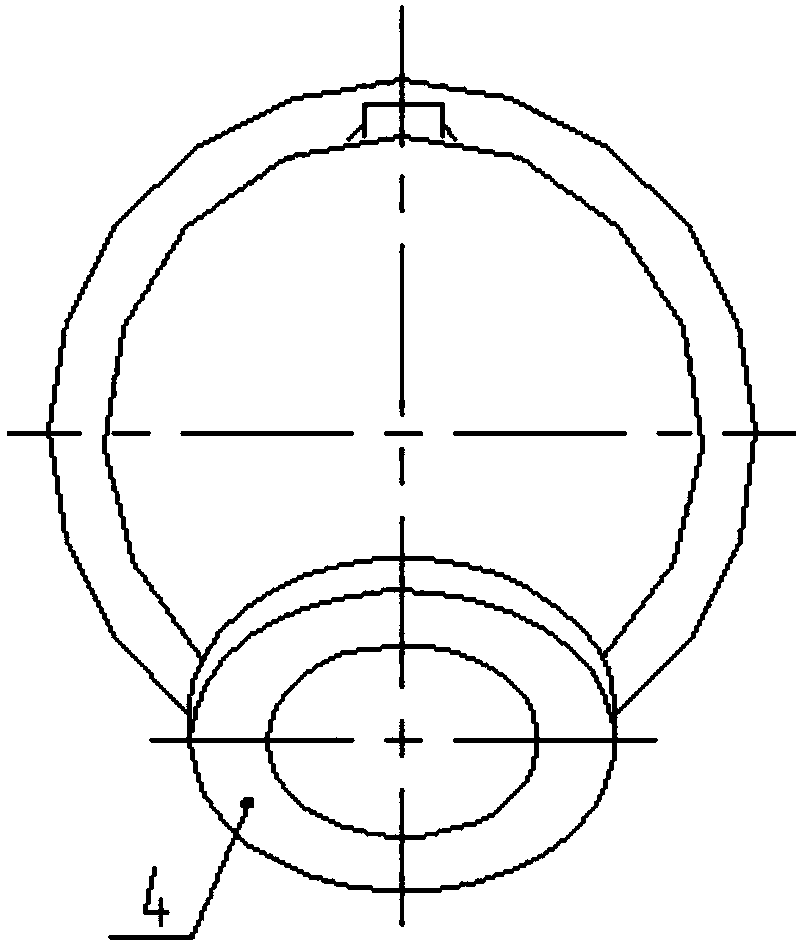

[0017] The high-performance casing socket housing shown in the figure includes flange I1, cylinder body 2, spherical head 3, support tube assembly 4, inflation hole flange 5; flange I1, spherical head 3 are respectively welded and fixedly connected At both ends of the main cylinder 2; the side wall of the spherical head 3 has holes, and the openings extend outward to form a support tube II3.1. The intersection of the side wall of the spherical head 3 and the support tube II3.1 is rounded Connection; The support tube assembly 4 is composed of an integrated support tube I4.1 and a support tube flange 4.2. The support tube I4.1 is welded and fixedly connected to the end of the support tube II3.1 on the side wall of the spherical head 3.

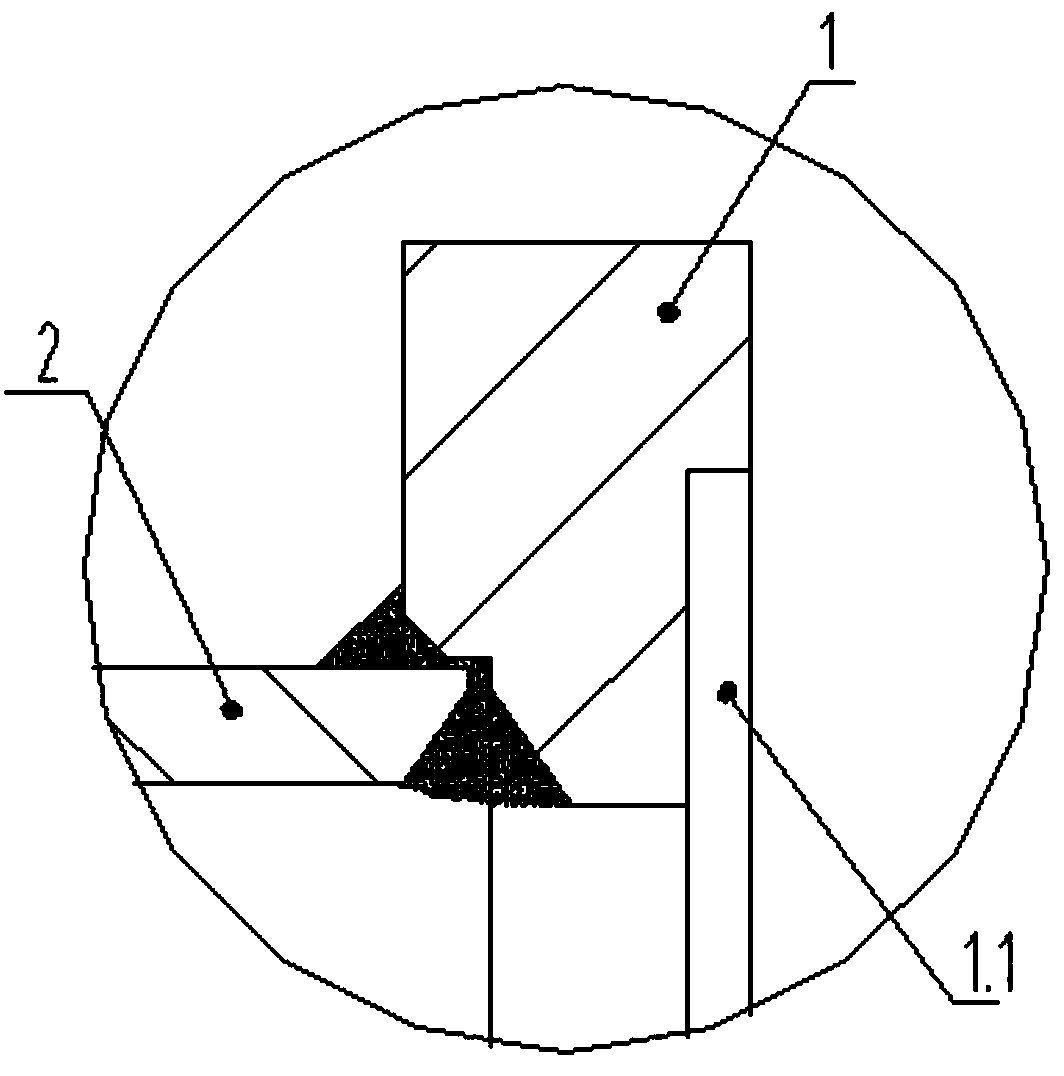

[0018] The outer end surface of the flange I1 is concave to form a groove 1.1, and the inner end surface of the groove 1.1 forms an inner sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com