Automobile anti-collision beam mounting structure and mounting method

A technology of installation structure and installation method, which is applied to bumpers, combustion engines, internal combustion piston engines, etc., can solve the problem of reducing the energy absorption effect of the anti-collision beam body, pulling off the anti-collision beam at the connection, and weakening the strength of the anti-collision beam 1. and other problems, to achieve the effect of avoiding the collision force transmission path, enhancing the strength, and improving the impact resistance of the car body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

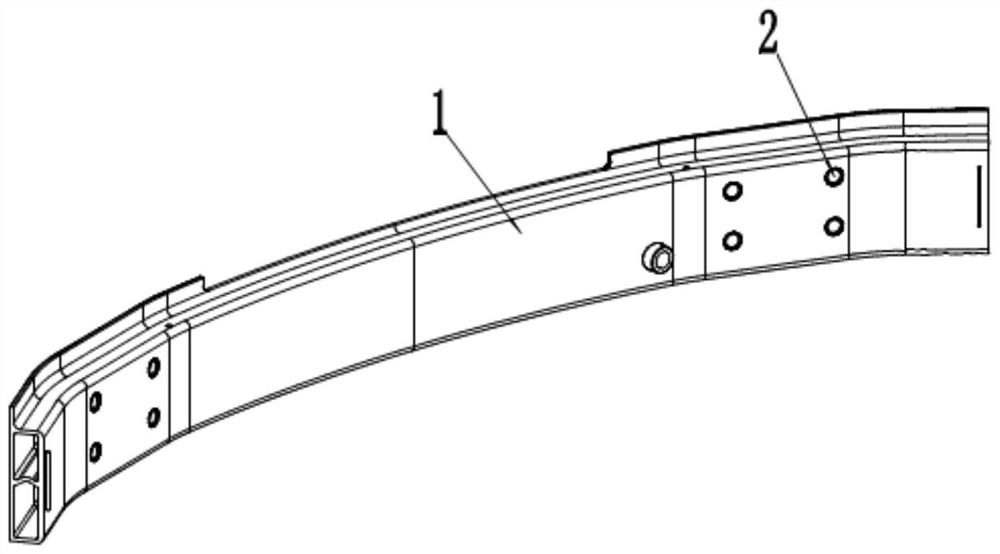

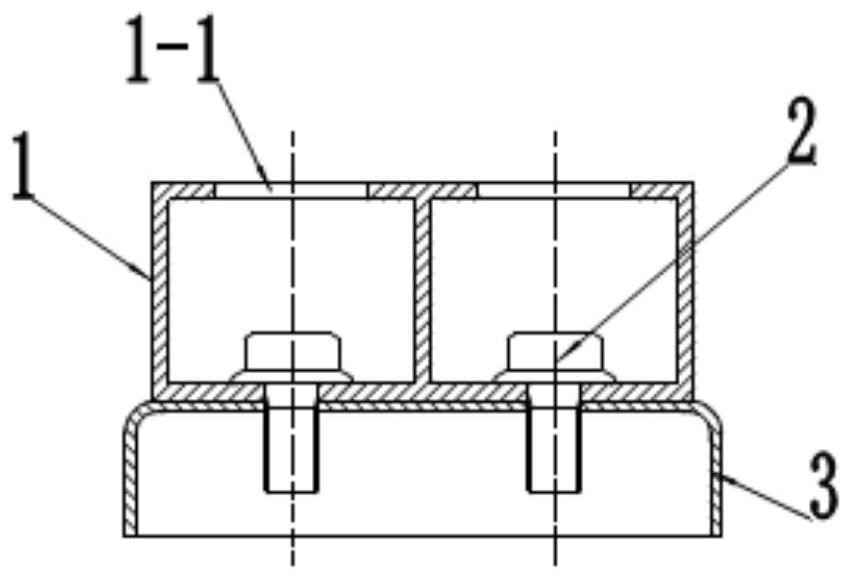

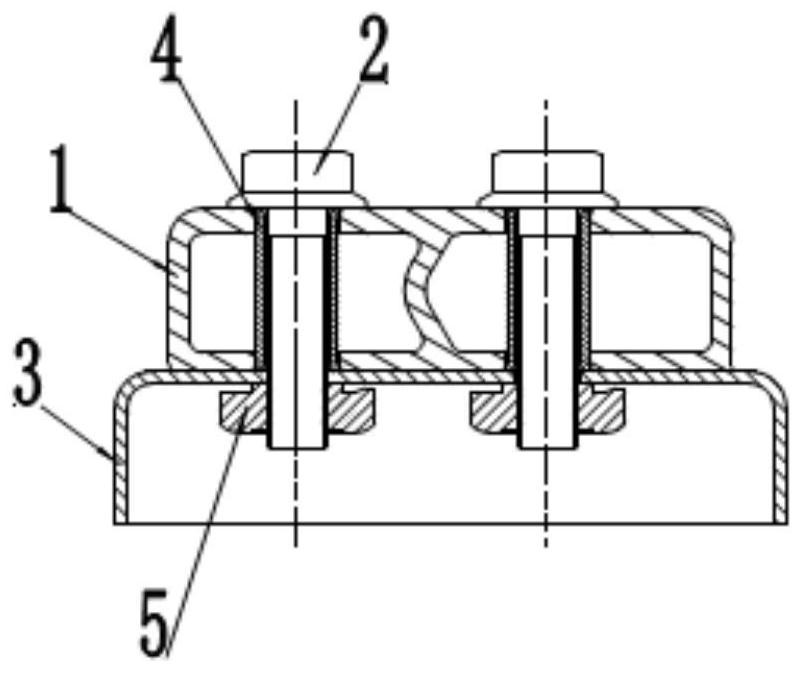

[0030] Referring to Figure 1, figure 2 , the anti-collision beam 1 of the car is a component of a cavity structure installed at the front end of the car body. When a frontal collision of the car body occurs, the impact energy can be absorbed by the collapse deformation of the anti-collision beam to reduce the damage to the car body. , in the prior art, the anti-collision beam 1 of the automobile and the body longitudinal beam 3 are connected and assembled by bolts 2, and the assembly structure is as follows: the bolts 2 pass through the holes 1-1 on the outer arc surface of the anti-collision beam 1 cavity. , directly screw the inner arc surface of the cavity 1 of the anti-collision beam with the end of the longitudinal beam 3 of the vehicle body. This installation structure needs to consider the operating space of the bolt 2 and the tightening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com