Ultimate strength test model design method of small-waterplane-area twin-hull ship under combined action of bending and torsion

A technology of small waterplane surface two-body and test model, which is applied in the field of ship structure engineering, can solve problems such as unfavorable ship development, structural deformation and collapse feature limitations, and achieve the effect of being conducive to development and realizing effective application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

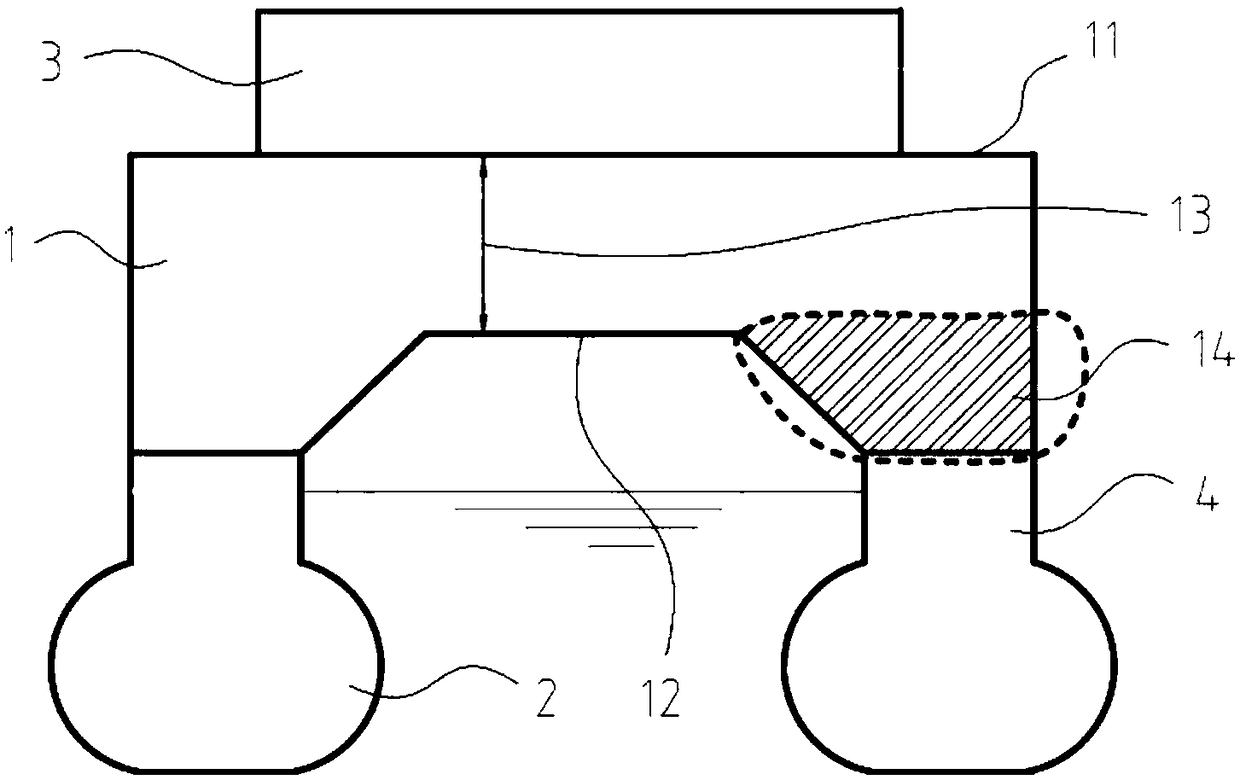

[0040] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 to attach Figure 10 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

[0041] figure 1 is a cross-sectional structure diagram of a small waterplane area catamaran; Figure 8 It is a design flow chart of a test model of a small waterplane area catamaran of the present invention. Such as figure 1 and Figure 8 As shown, the design method for the combined ultimate strength test model of the small waterplane area catamaran provided by this embodiment includes the following steps:

[0042] Step 1, carry out the structural simplification design of test model;

[0043] The combined bending and torsional ultimate strength test model of the small waterplane catamar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com