A Micro Engine Flame Tube with Two-Stage Guide Vanes

A technology of guide vanes and flame tubes, which is applied in the field of micro-engines, can solve the problems of limited improvement of flame surface stability, poor stability, and small range of low-speed areas, and achieve the effects of preventing carbon deposition, uniform mixing, and high turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described now in conjunction with accompanying drawing:

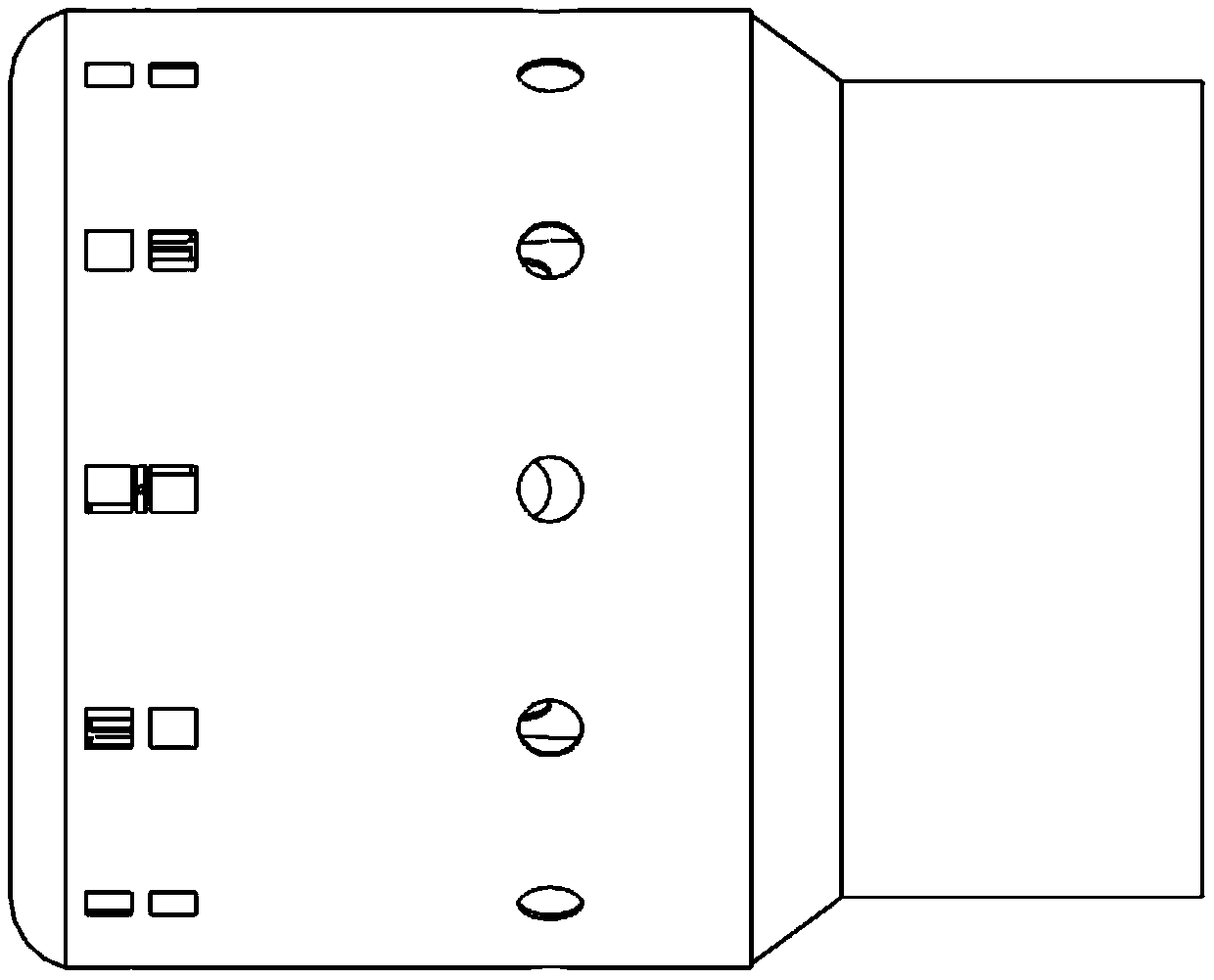

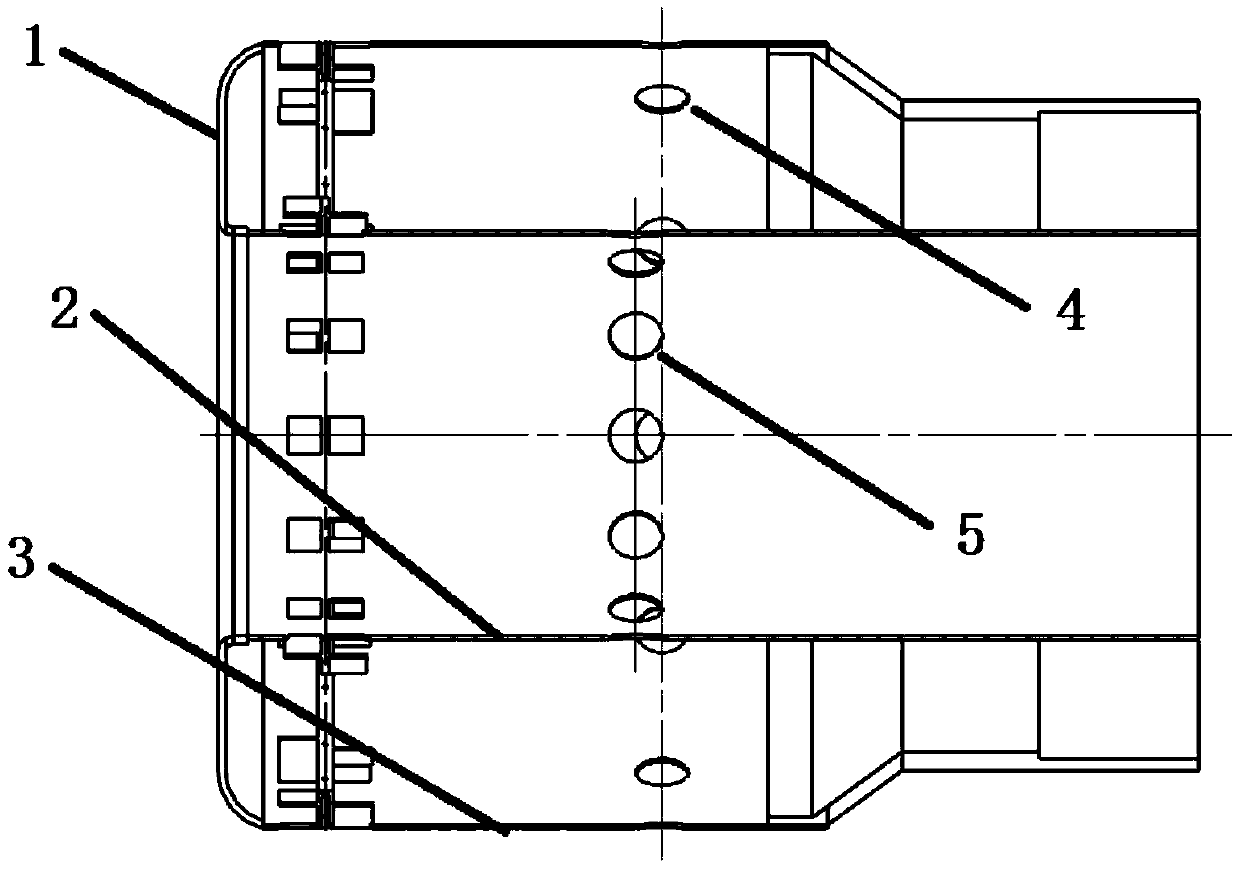

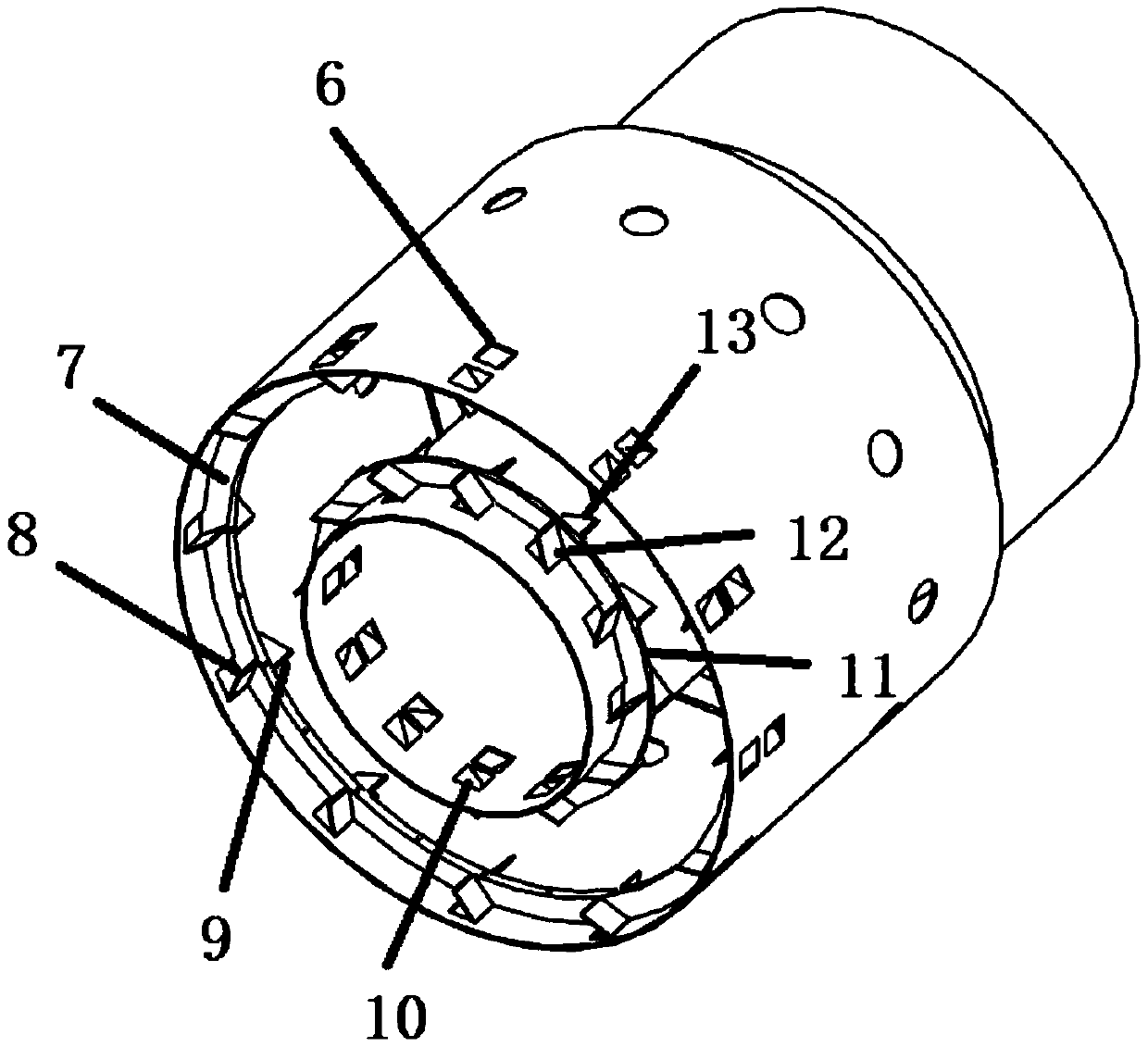

[0022] combine figure 1 , figure 2 , image 3 with Figure 4 , the invention provides a structural design scheme of a micro-engine flame cylinder with two-stage guide vanes. figure 1 is the front view of the flame tube, figure 2 is the sectional view of the flame tube, image 3 In order to remove the three-dimensional schematic diagram of the flame tube on the front face, Figure 4 Sectional view of the split rib.

[0023] according to figure 2 , image 3 with Figure 4 As shown, the present invention rationally designs the main combustion holes of the inner and outer shells of the flame cylinder and sets up two-stage guide vanes, so that the airflow entering the flame cylinder becomes a swirling airflow, and the inwardly rotating airflow and the outwardly rotating The air flow meets and opposes inside the flame tube to form a low-velocity zone. Separation ribs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com