High-pressure double-cavity multipurpose water delivery mechanism

A high-pressure, water-inlet chamber technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of small water pump head, inability to go deep into underwater operations, low efficiency, etc., to achieve large head and save labor time , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

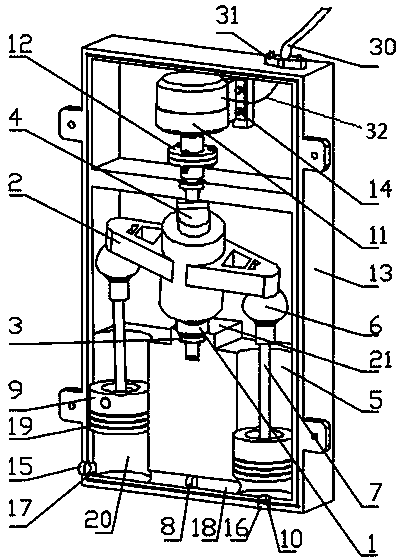

[0032] Embodiment 1: as Figure 1-9 As shown, the high-pressure double-cavity water delivery device includes transmission shaft II1, transmission frame 2, bearing I3, transmission shaft I4, water inlet chamber 5, ball joint 6, piston rod 7, piston 9, water inlet 10, motor 11. Flange coupling 12, box body 13, water outlet 17, water delivery channel 18, water outlet chamber 20; the box body 13 is a hollow sealed box, and the lower part of the box body 13 is provided with a water inlet chamber 5 and a water outlet chamber 20, and the motor 11 is fixed on the inner upper part of the box body 13 by screws 14, the output shaft of the motor 11 is connected with the short shaft 22 on the upper end of the transmission shaft I4 through the flange coupling 12, and the transmission frame 2 includes two outriggers 24 and a base 25, two The outrigger is symmetrically fixed on the upper part of the base, and a through hole 27 is opened at the center of the base. The long shaft 23 at the lowe...

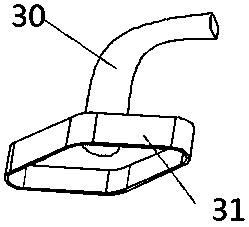

Embodiment 2

[0033] Embodiment 2: as figure 1 , 8 , 9, and 10, the structure of this embodiment is the same as that of Embodiment 1, the difference is that the piston 9 is provided with a sealing rubber ring 19, and the sealing rubber ring 19 is closely matched with the inner wall of the water inlet chamber 5 or the water outlet chamber 20, and the transmission frame 2, the ball The head universal joint 6 and the piston rod 7 are connected by threads, the box body 13 is provided with a handle, the electric wire 32 connecting the motor and the power supply is arranged in a soft hollow tube 30, and the hollow tube 30 is sealed by a rope cover 31 fixed on the case 13.

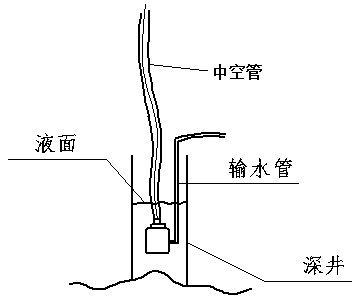

[0034] like Figure 11 , 12 As shown, the device is placed under the water surface of a deep well or reservoir. After the motor 11 is started, the transmission shaft I4 is driven to rotate through the flange coupling 12, and the rotational movement of the transmission shaft I4 and the transmission shaft II1 makes the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com