Horizontal reinforced concrete steel pipe pile pre-supporting and protecting method

A technology of reinforced concrete and steel pipe piles, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of easy crack settlement, unsatisfactory strength and rigidity, insufficient strength and rigidity, etc., so as to improve the safety performance of the structure. and durability, improved safety, high strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

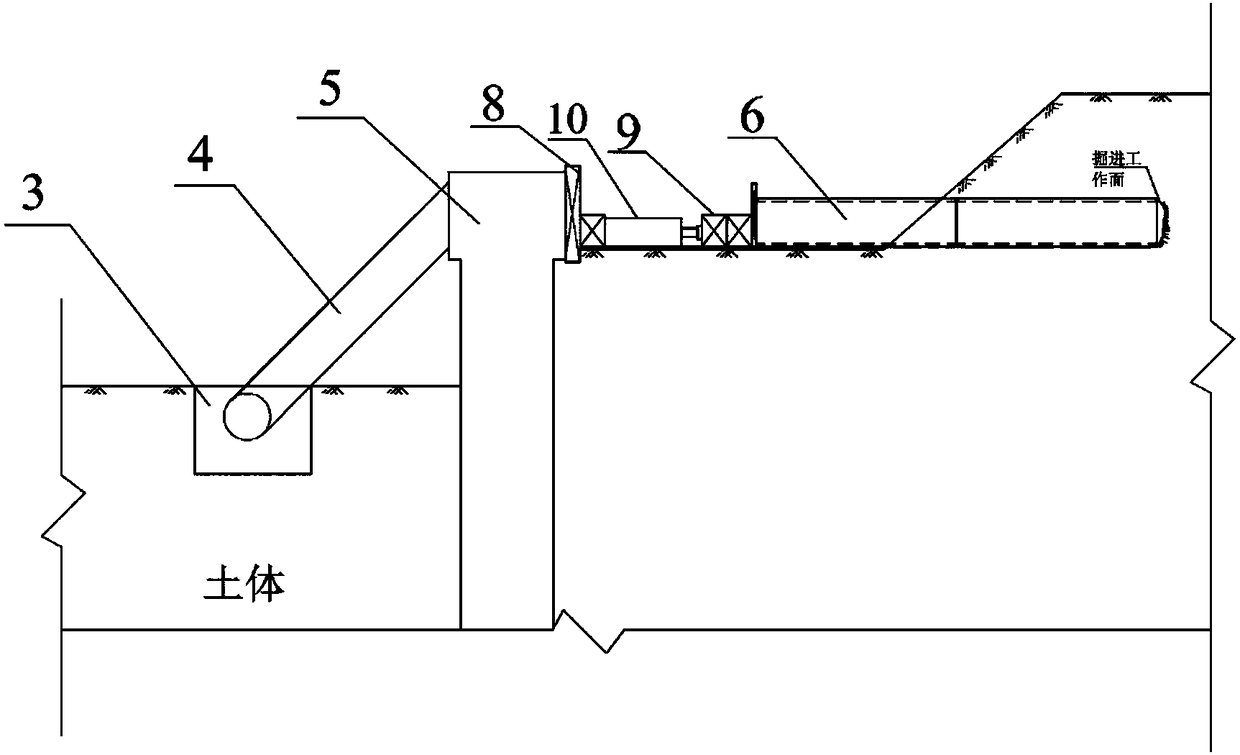

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

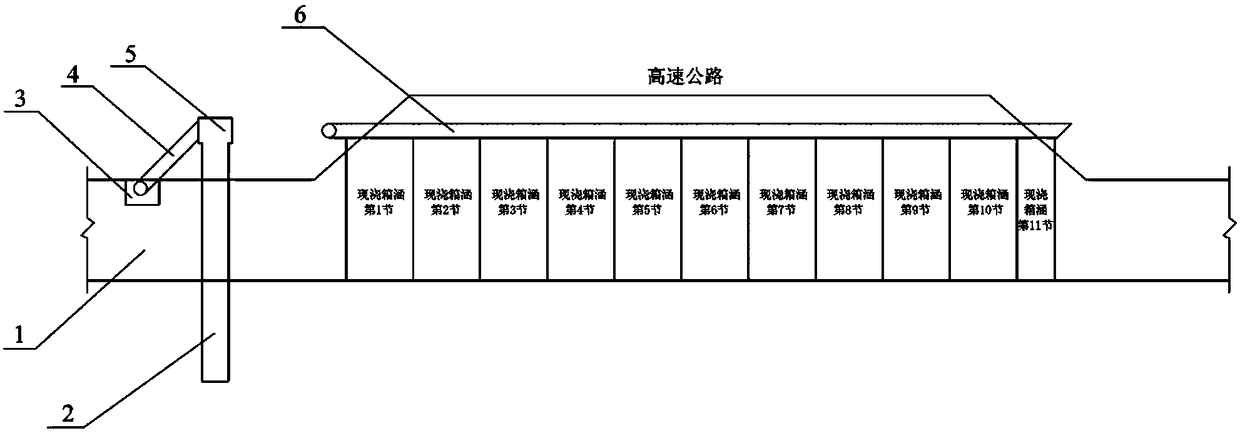

[0033] The super-large box culvert 7 mentioned in the present invention is a cast-in-place box culvert with a box chamber of 16m×8.5m; the jacking device 10 adopts a jack.

[0034] A method for pre-supporting horizontal reinforced concrete steel pipe piles, comprising the following steps:

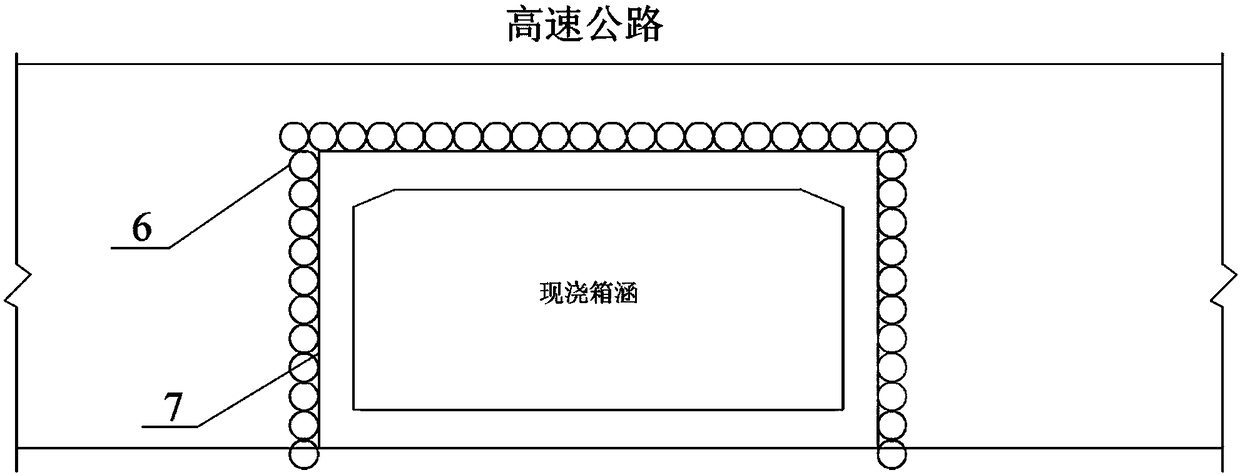

[0035] Step 1: jacking in multiple steel pipes 6-1 along the outer contour of the super-large box culvert 7 designed in advance;

[0036] Step 2: After the steel pipe 6-1 penetrates the subgrade, insert a reinforcement cage 6-2 into the steel pipe 6-1 and pour concrete 6-3;

[0037] Step 3: The adjacent steel pipes 6-1 are engaged with each other to form a rigid rectangular shed along the outer contour of the super-large box culvert 7;

[0038] Step 4: Carry out construction of super large box culvert 7.

[0039] Further, during the jacking process of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com