Piled retaining wall embankment

A pile-supported and retaining wall technology, applied in the field of civil engineering, can solve the problems of waste of vertical bearing capacity of side piles, increase of expropriation costs, waste of land resources in occupied area, etc., to improve the ability to resist differential deformation and to restrain horizontal The stress and the effect of reducing the number of piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The pile-supported retaining wall embankment involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0024]

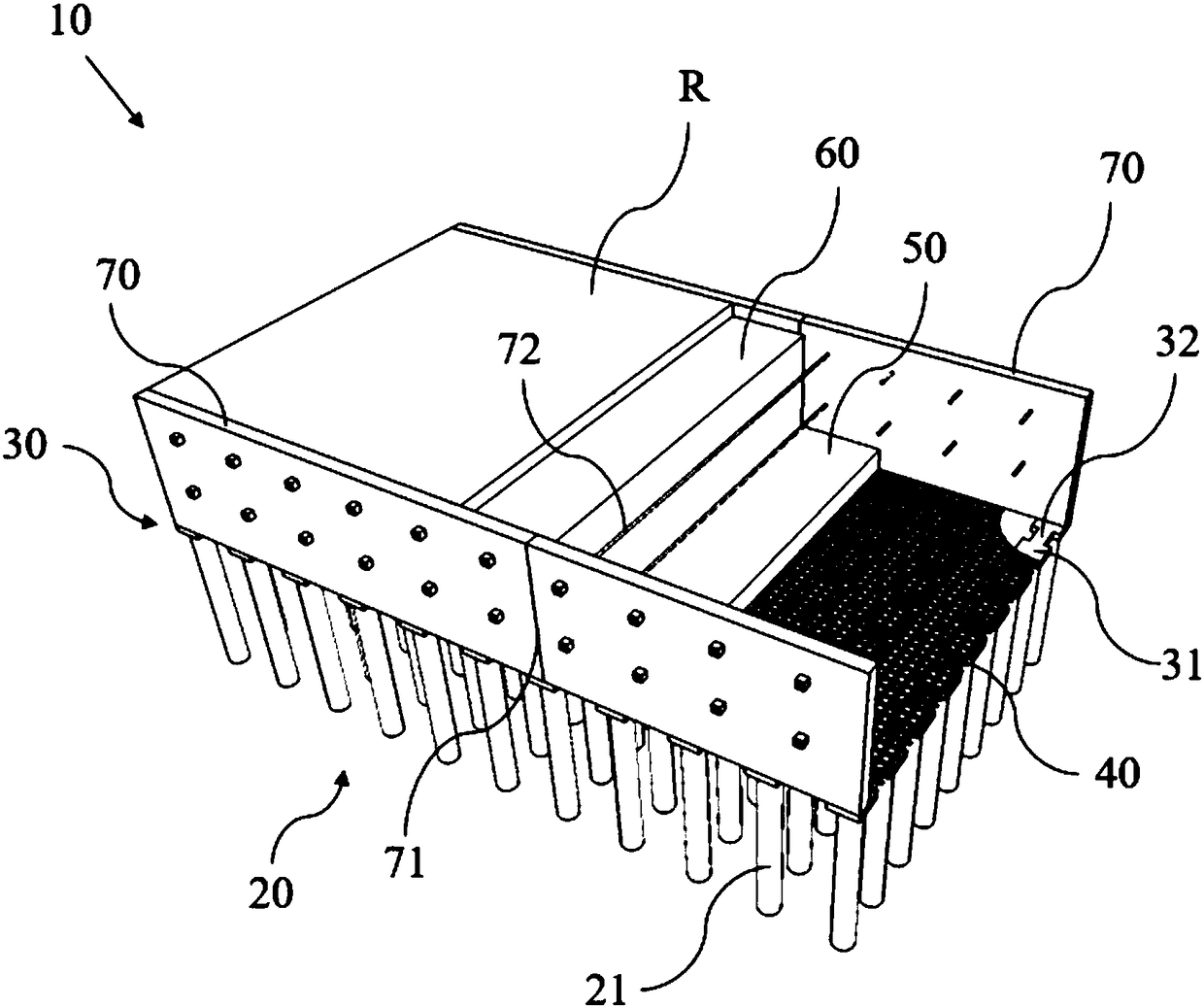

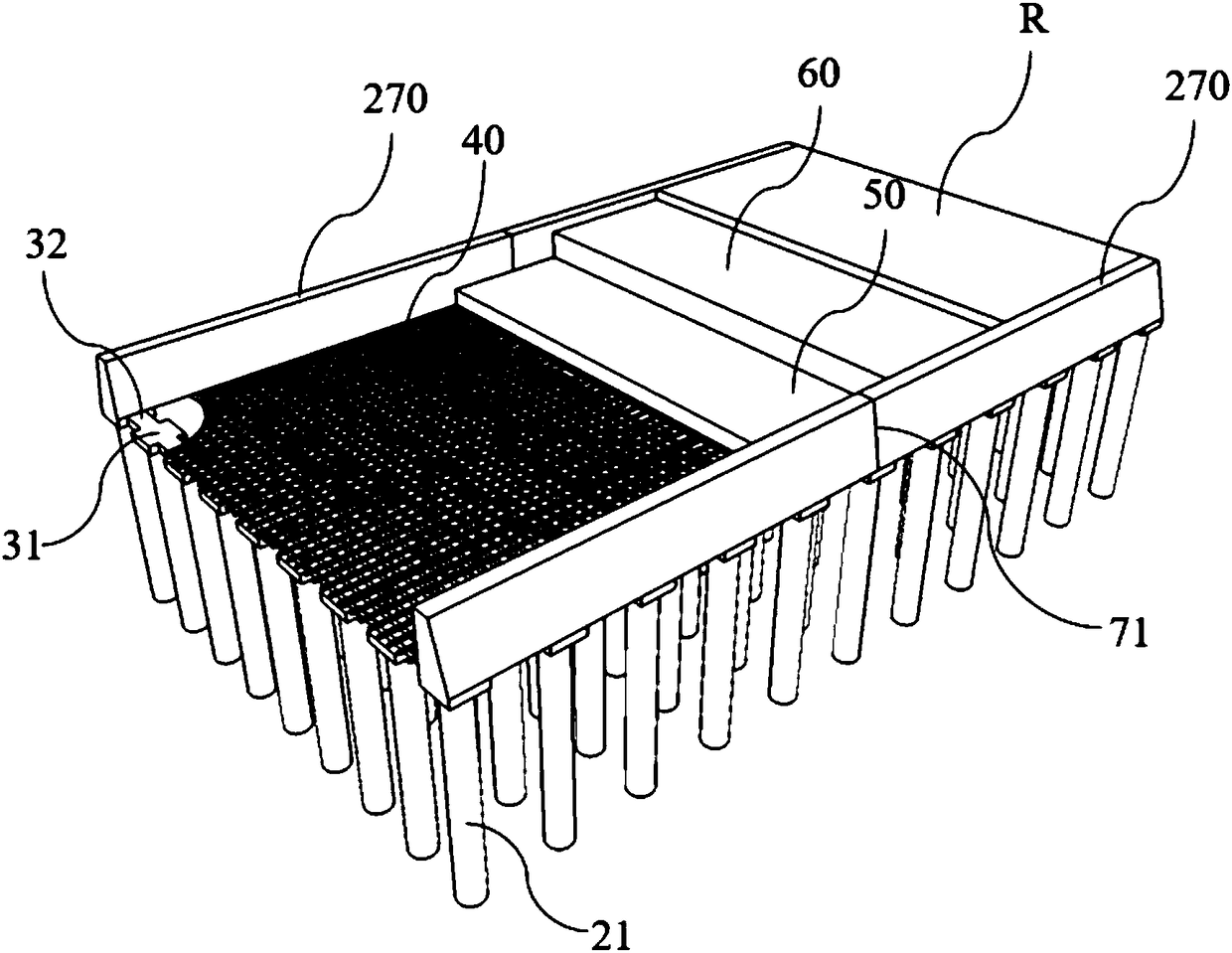

[0025] Such as figure 1 As shown, the pile-supported retaining wall embankment 10 includes: a bearing part 20 , a connecting layer 30 , a geogrid layer 40 , a cushion layer 50 , an embankment layer 60 , and a retaining wall 70 .

[0026] The bearing part 20 includes multiple groups of vertical bearing piles 21, and the multiple groups of vertical bearing piles 21 are arranged in a rectangular array, and the pile distance of the vertical bearing piles 21 is 4 to 8 times the pile diameter, and the pile diameter of each vertical bearing pile 21 The diameter is 300-600mm, and the depth of the pile top entering the pile cap should not be less than 50mm.

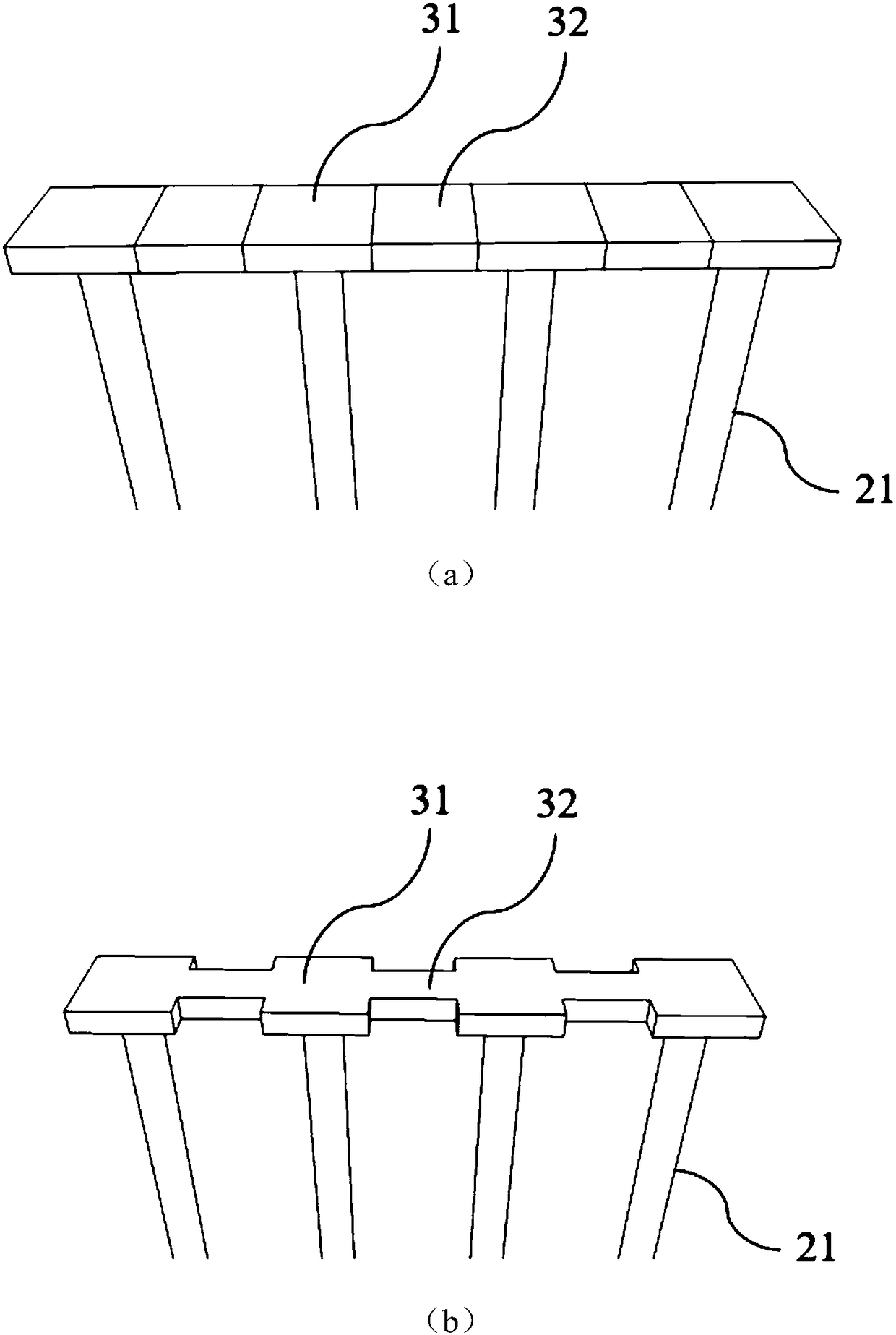

[0027] The connecting layer 30 includes multiple sets of pile caps 31 and multiple sets of coupling beams 32 . Each group of pile caps 31 corresponds to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com