Method for preparing Mg2Si/Al composite material in situ by laser deposition

A technology of laser deposition and composite materials, applied in metal material coating process, coating and other directions, can solve the problems of mixing impurities, sharp corner cracks, coarse Si, etc., to achieve easy operation, reduce Mg loss, and small grain size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

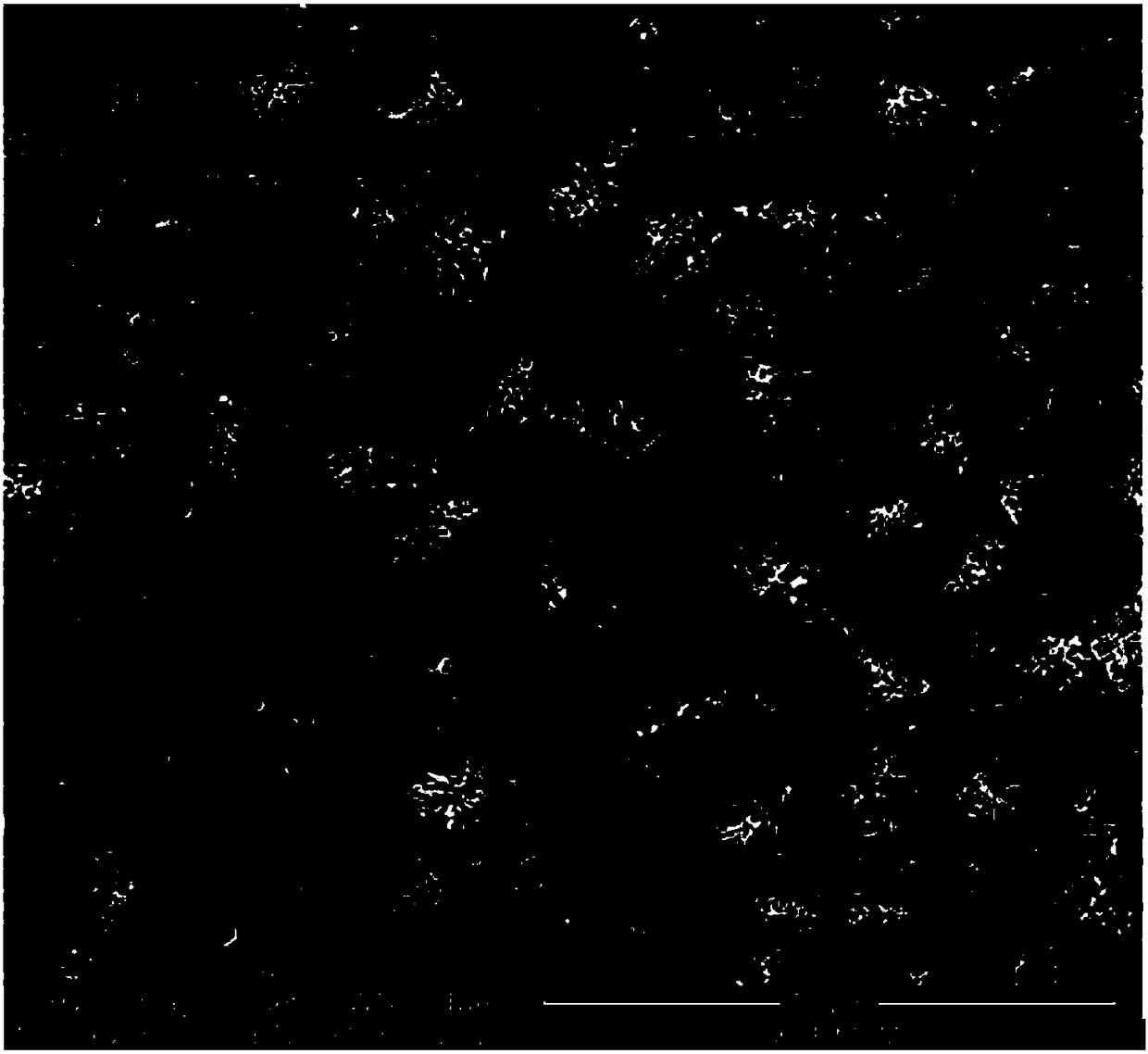

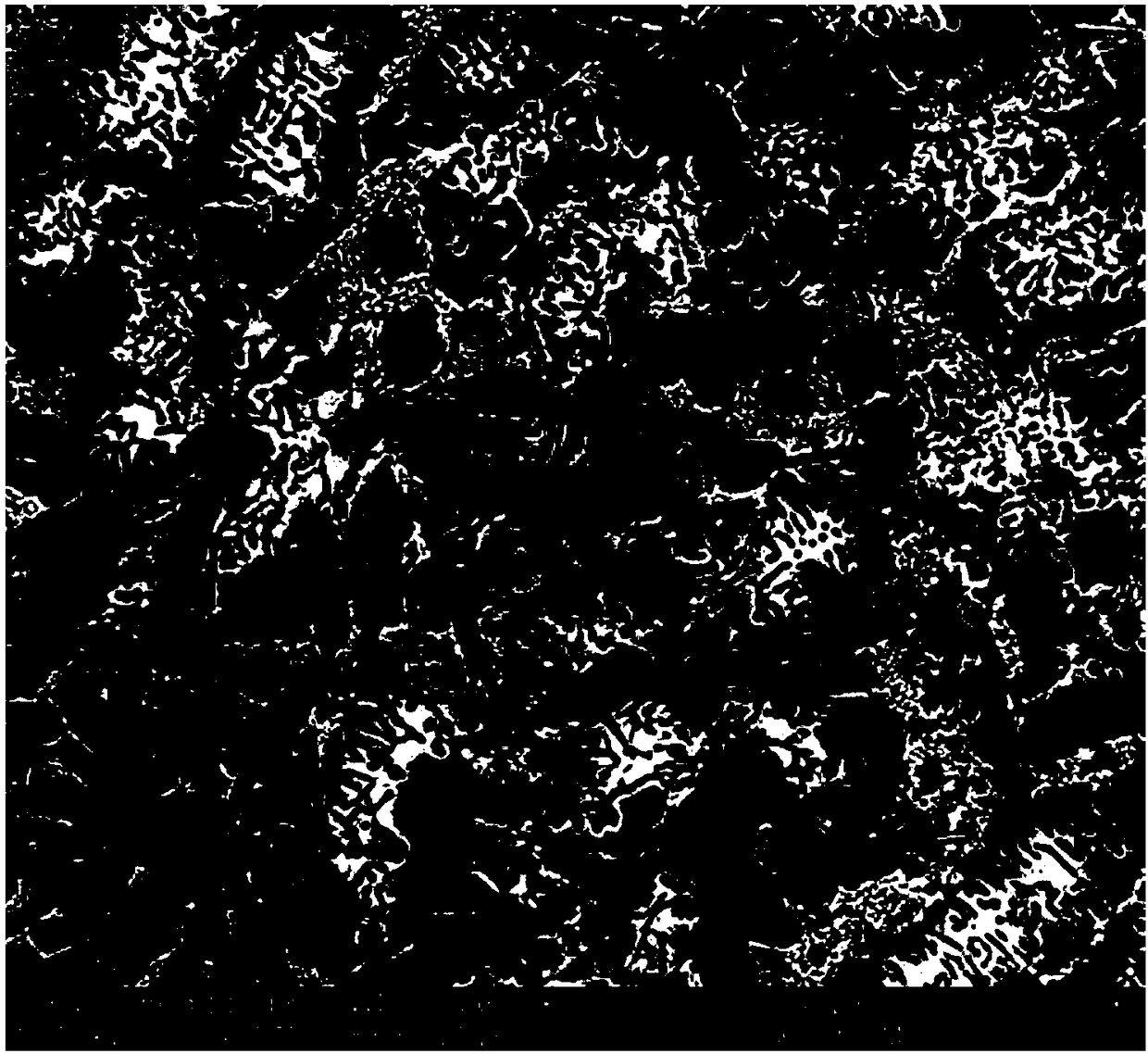

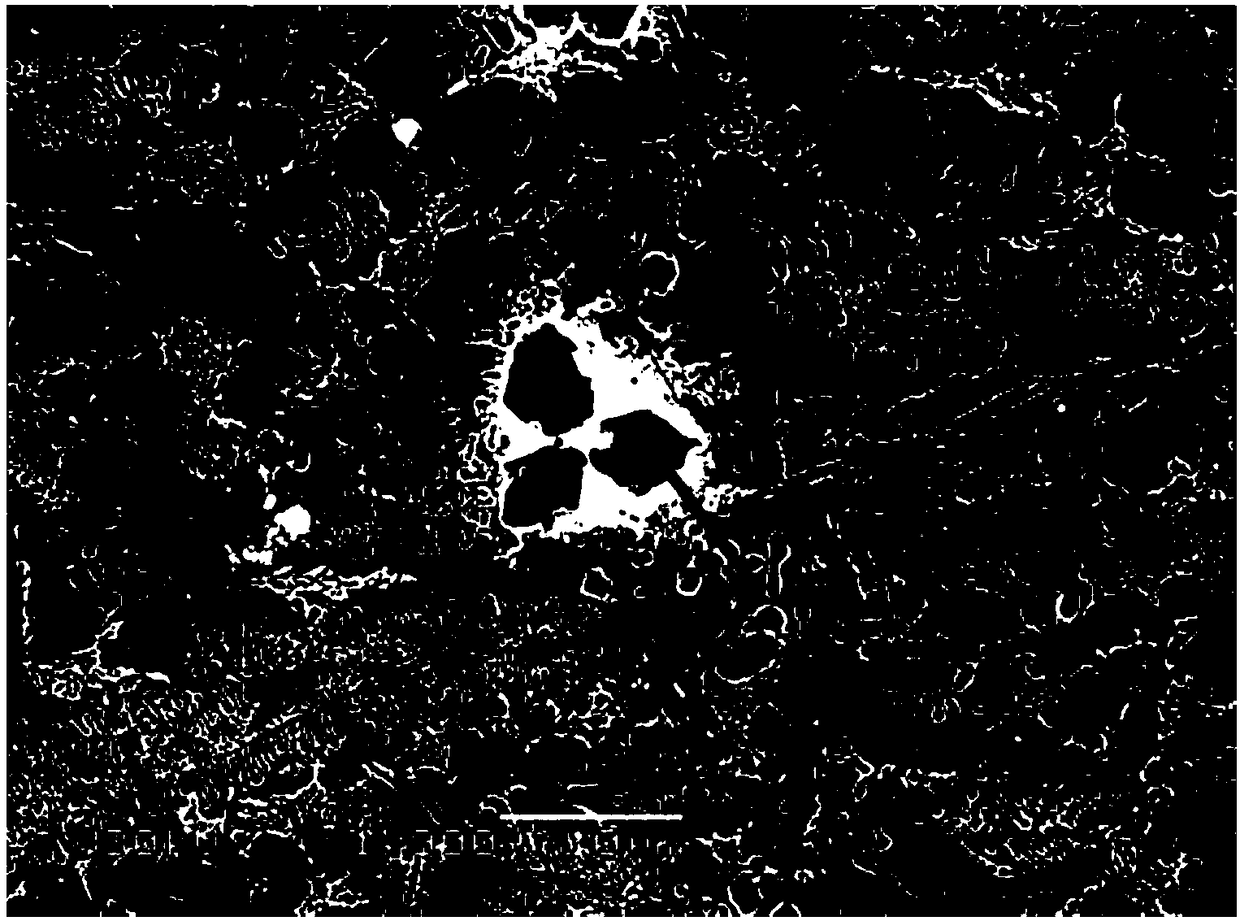

Image

Examples

Embodiment 1

[0026] In-Situ Preparation of Mg by Laser Deposition 2 The method for Si / Al composite material, comprises the following steps:

[0027] (1) Pre-treat the surface of the laser-deposited substrate, clean the dirt, rust and dust on the surface of the substrate, and dry it for later use.

[0028] (2) The Al-50%Mg alloy powder and Al-9%Si alloy powder are mixed according to the mass ratio of Al:Mg:Si of 7:2:1 in a planetary ball mill at a speed of 200r / min for two hours. uniform.

[0029] (3) Put the ball-milled powder into a vacuum drying oven, dry it at 60°C for 2 hours, lay it flat on the flat plate in the groove of the fixture, spray the binder solution evenly to form a uniform water layer, and put it together with the concave The grooved plate is stably placed in a vacuum drying oven, heated and hardened under vacuum at 50-60° C. for 5 hours, and the grooved plate is removed. Obtain the required pre-slices and store them in a vacuum-dried environment.

[0030] (4) Place th...

Embodiment 2

[0035] In-Situ Preparation of Mg by Laser Deposition 2 The method for Si / Al composite material, comprises the following steps:

[0036] (1) Pre-treat the surface of the laser-deposited substrate, clean the dirt, rust and dust on the surface of the substrate, and dry it for later use.

[0037] (2) Al-50% Mg alloy powder and Al-9% Si alloy powder are mixed according to the Mg: Si mass ratio of 2:1, wherein Al: Mg: Si is 7:2:1, in the planetary ball mill Rotate at 200r / min for two hours to make the powder evenly mixed.

[0038] (3) Put the ball-milled powder into a vacuum drying oven, dry it at 60°C for 2 hours, lay it flat on the flat plate in the groove of the fixture, spray the binder solution evenly to form a uniform water layer, and put it together with the concave The grooved plate is stably placed in a vacuum drying oven, heated and hardened under vacuum at 50-60°C for 5 hours, the grooved plate is removed to obtain the required pre-set, and stored in a vacuum-dried envi...

Embodiment 3

[0041] In-Situ Preparation of Mg by Laser Deposition 2 The method for Si / Al composite material, comprises the following steps:

[0042] (1) Pre-treat the surface of the laser-deposited substrate, clean the dirt, rust and dust on the surface of the substrate, and dry it for later use.

[0043] (2) Al-50% Mg alloy powder and Al-9% Si alloy powder are mixed according to the Mg: Si mass ratio of 2:1, wherein Al: Mg: Si is 7:2:1, in the planetary ball mill Rotate at 200r / min for two hours to make the powder evenly mixed.

[0044] (3) Put the ball-milled powder into a vacuum drying oven, dry it at 60°C for 2 hours, lay it flat on the flat plate in the groove of the fixture, spray the binder solution evenly to form a uniform water layer, and put it together with the concave The grooved plate is stably placed in a vacuum drying oven, heated and hardened under vacuum at 50-60°C for 5 hours, the grooved plate is removed to obtain the required pre-set, and stored in a vacuum-dried envi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com