Residual oil hydrogenation refining process for stopping and starting fractionating tower system and changing direction of cold low-fraction oil

A residual oil hydrogenation and fractionation tower technology, which is applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of long separation process and high energy consumption, increase the temperature of raw materials entering the furnace, and reduce fuel consumption. , process and operation simplification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

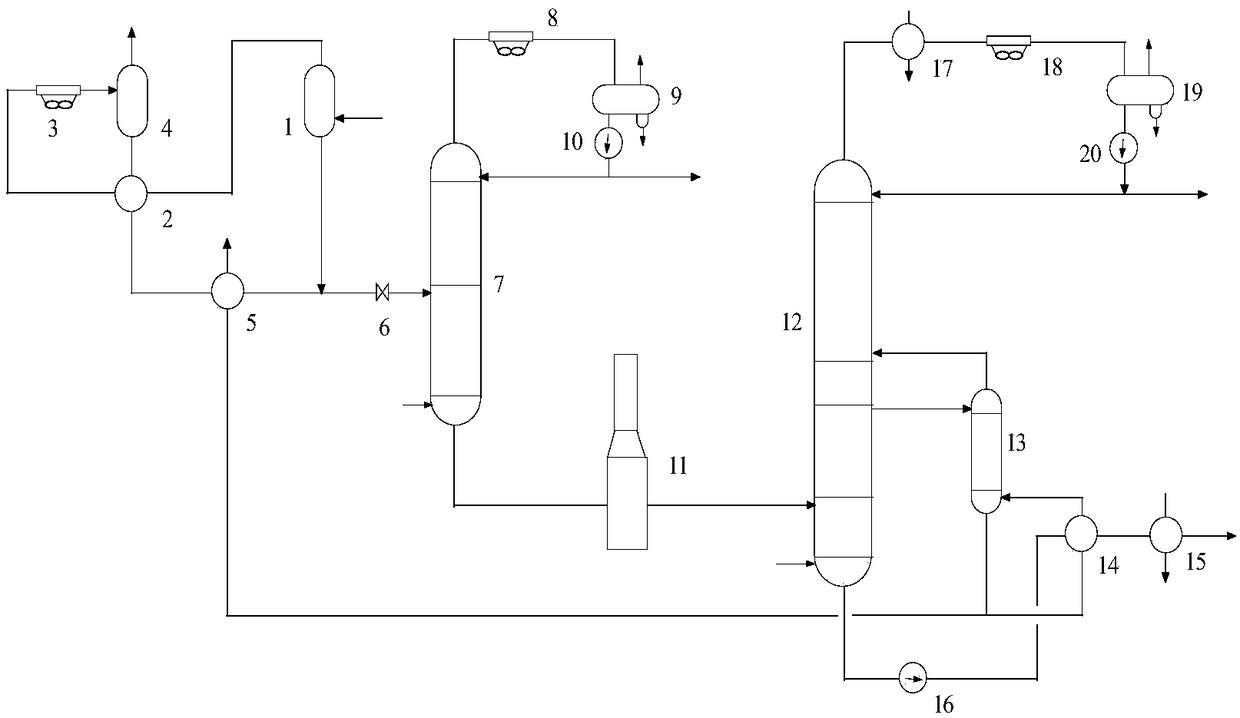

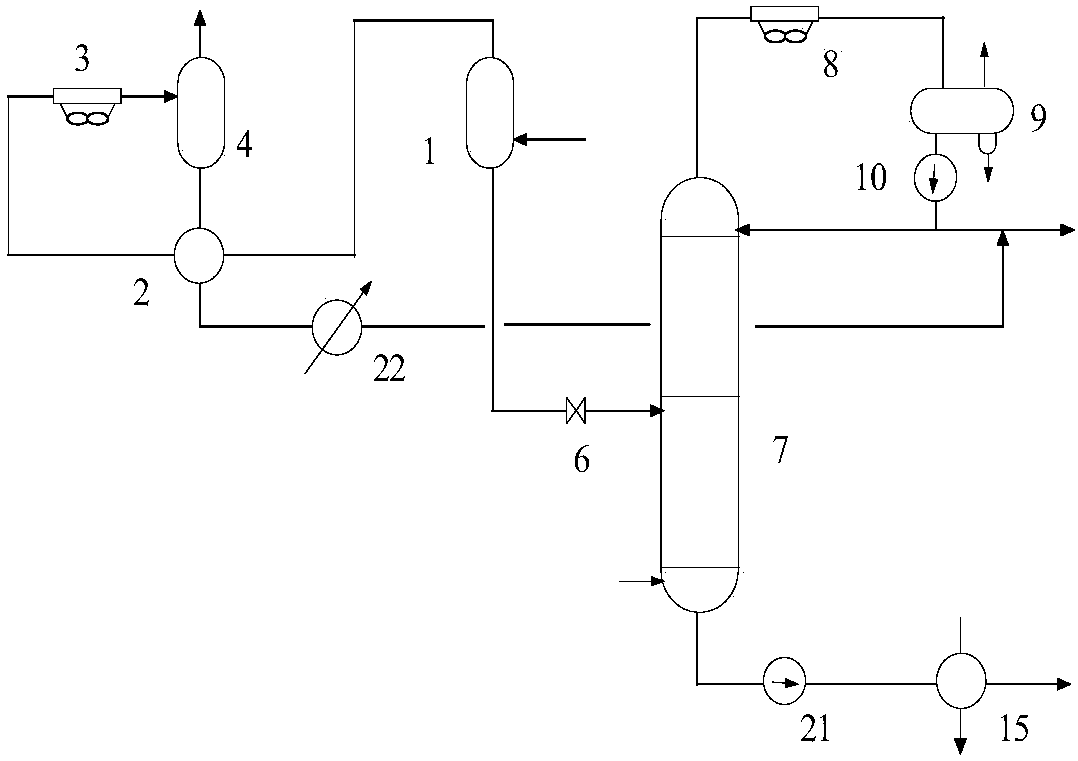

[0036] A kind of residual oil hydrotreating flow process of the present embodiment, its process flow chart is as follows figure 2 shown. Compared with the process of the comparison example, the following improvements were implemented:

[0037] (1) The cold and low-separation oil from the cold and low-separation tank 4 passes through the cold and low-separation oil once to the hot and low-separation gas once. After heat exchanger 2 exchanges heat with the hot and low-separation gas, it does not enter H 2 S stripper 7, but after being cooled to about 40 ° C by circulating water in the secondary circulating water cooler 22 of cold low-separation oil, and H 2 The unstable naphtha at the top of the S stripper is mixed, and sent to the gasoline and diesel hydrotreating unit (such as entering its H 2 S stripper), with the help of its separation system to complete the separation of gas, naphtha and diesel fractions.

[0038] (2) Shut down H 2 The fractionation tower system flow a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com