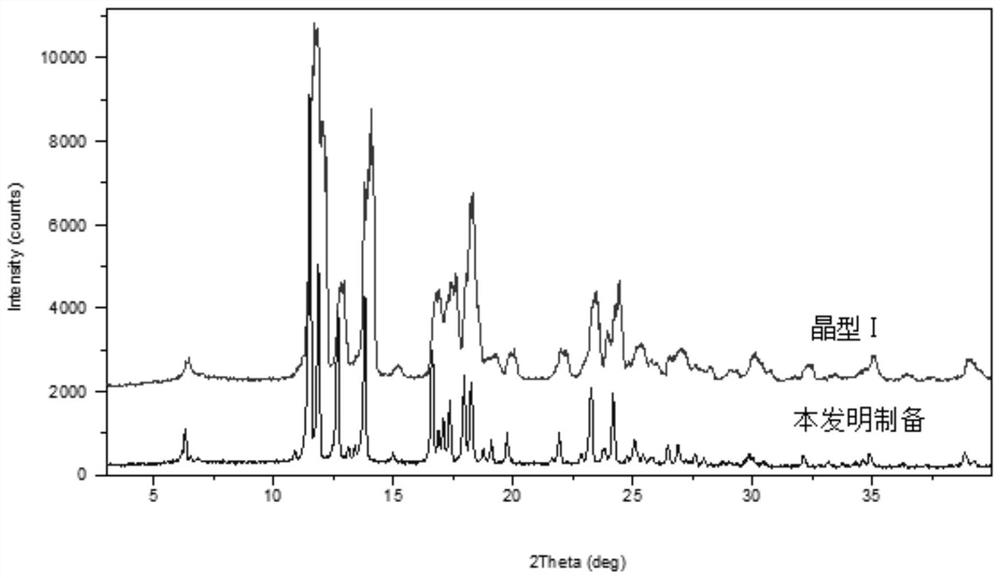

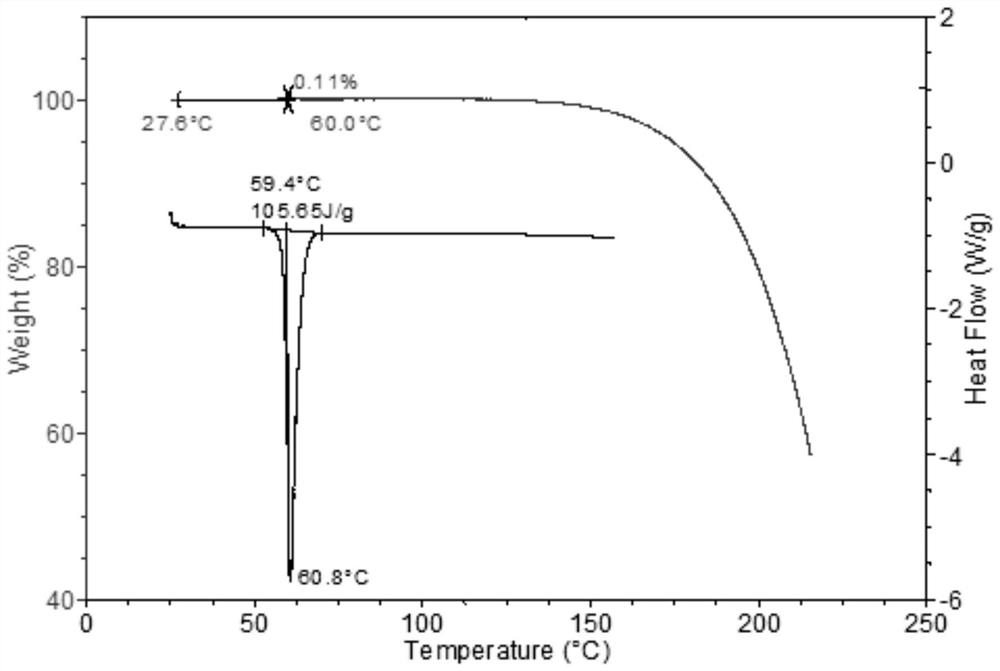

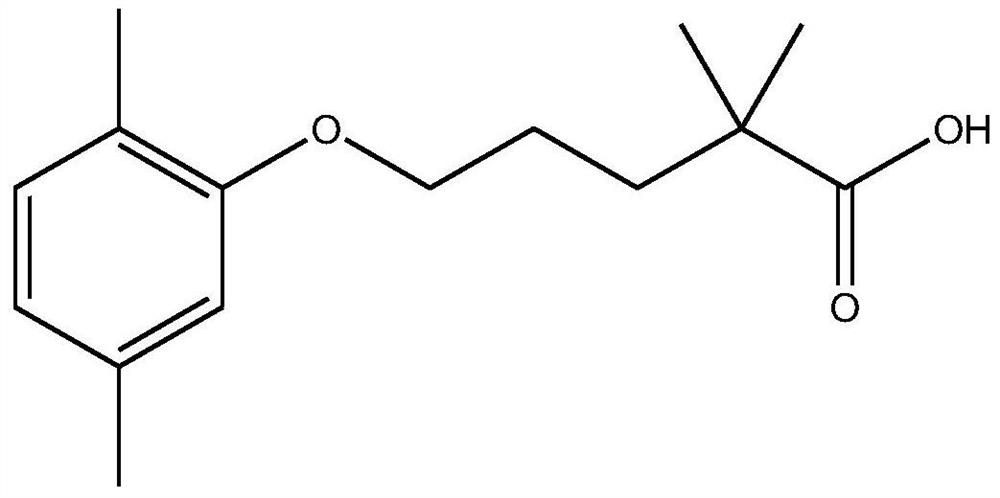

Preparation method of gemfibrozil crystal form I

A technology of fibrozil crystal form and gemfibrozil, which is applied in the field of medicinal chemistry, can solve the problems of large amount of three wastes and low yield, and achieve the effects of reducing the generation of three wastes, high yield, and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, a preparation method of gemfibrozil crystal form I:

[0027] Take 10g of gemfibrozil and add it to 50ml of ethanol, heat up to 30°C and stir until the gemfibrozil dissolves to obtain the gemfibrozil ethanol solution;

[0028] Slowly add 20ml of water to gemfibrozil ethanol solution (dropping time is 60-90 minutes), during the dropping process, solids will be precipitated, then lower the temperature to 10°C, stir for 2 hours, filter to obtain solids, 40°C After vacuum drying for 7-8 hours, 8.1 g of gemfibrozil crystal form was obtained, with a yield of 81%.

Embodiment 2

[0029] Embodiment 2, a preparation method of gemfibrozil crystal form I:

[0030] Take 10g of gemfibrozil and add it to 25ml of ethanol, heat up to 40°C and stir until the gemfibrozil dissolves to obtain the gemfibrozil ethanol solution;

[0031] Slowly add the gemfibrozil ethanol solution obtained dropwise (dropping time is 60 to 90 minutes) into a solution composed of 15ml of water and 6ml of ethanol. After the dropwise addition is completed, cool down to 10°C, stir for 2 hours, and filter. The obtained solid was vacuum-dried at 40° C. for 7 to 8 hours to obtain 8.5 g of gemfibrozil crystal form I, with a yield of 85%.

[0032] Remarks: The filtrate obtained by filtering is concentrated in a conventional manner, and the concentrated substrate is discarded to obtain an ethanol-water solution, which is prepared according to the ethanol-water solution ratio (1:2.5) described in Example 2 above, so as to realize recycling (recycling The number of times is at least 5 times), and...

Embodiment 3

[0034] Take 10g of gemfibrozil and add it to 20ml of ethanol, heat up to 50°C and stir until the gemfibrozil dissolves to obtain the gemfibrozil ethanol solution;

[0035] Slowly add the gemfibrozil ethanol solution obtained dropwise (dropping time is 60 to 90 minutes) into a solution composed of 12ml of water and 6ml of ethanol. After the dropwise addition is completed, cool down to 20°C, stir for 1 hour, and filter. The obtained solid was vacuum-dried at 40° C. for 7 to 8 hours to obtain 8.7 g of gemfibrozil crystal form I, with a yield of 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com