Cable winding device

A winding device and cable technology, which is applied in transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems such as the winding device cannot work when the winding device is shut down, the production efficiency is reduced, and the continuous production capacity is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

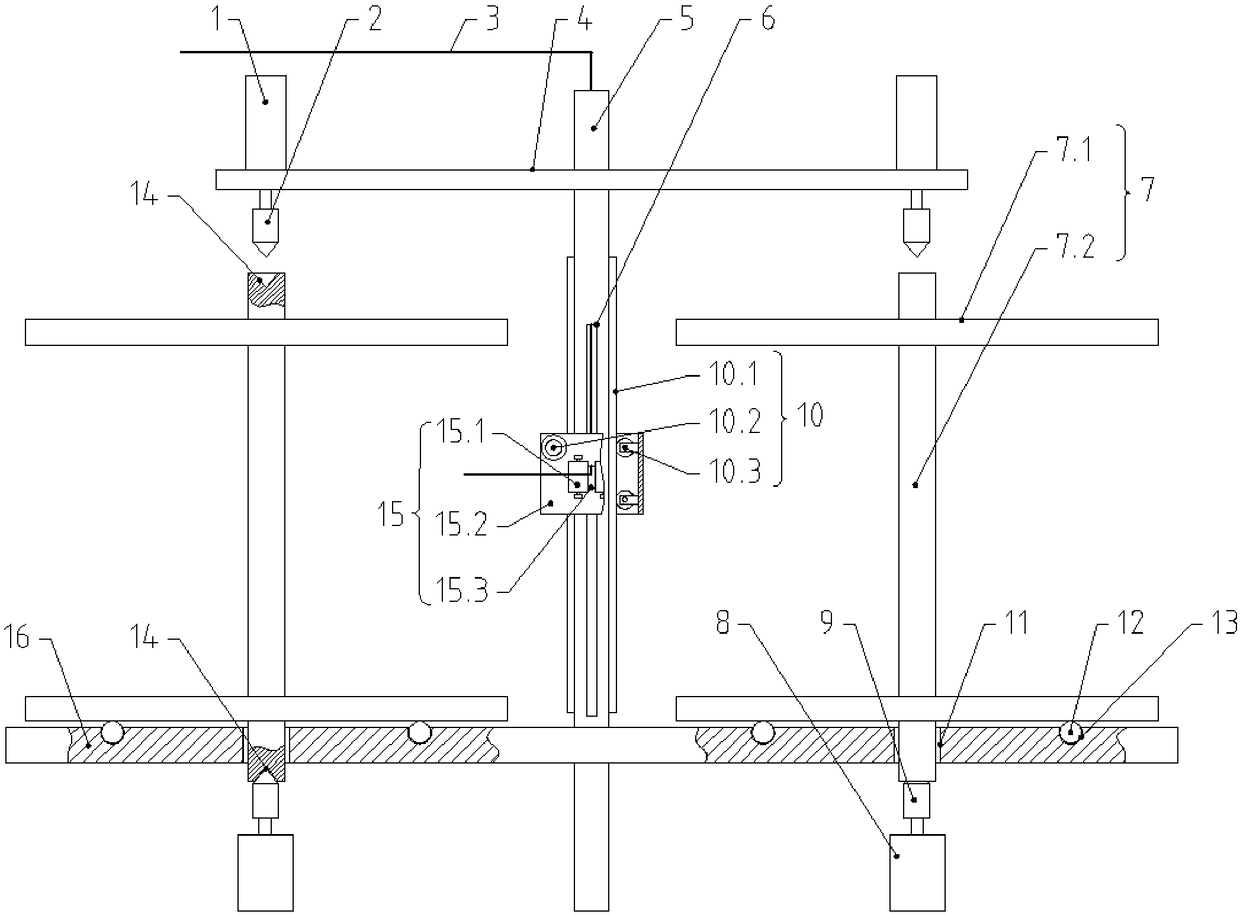

[0018] A cable 3 winding device, including a bracket and a winding reel 7 arranged on the bracket, the winding reel 7 includes a support rod 7.1 and baffles 7.2 sleeved at both ends of the support rod 7.1, and the bracket includes a vertically arranged hollow pillar 5. A horizontal support plate 16 is provided on the outer wall of the bottom of the hollow pillar 5. On the support plate 16, winding discs 7 are provided on both sides of the hollow pillar 5. The support plate 16 is provided with a through hole that can accommodate the end of the support rod 7.1 11. A drive mechanism that can contact and cooperate with the end of the support rod 7.1 is provided under the support plate 16. A cable 3 is provided inside the hollow support 5. An opening 6 for the cable 3 to pass through is vertically opened on the hollow support 5. On the hollow support 5 A wire mechanism 15 that can move up and down is sleeved.

[0019] The cable 3 enters the inside of the hollow pillar 5 from the to...

Embodiment 2

[0022] This embodiment improves on the basis of Embodiment 1:

[0023] The drive mechanism includes a drive motor 8, the output end of the drive motor 8 is provided with a connection block a9 that can be in contact with the end surface of the support rod 7.1, the end of the connection block a9 is tapered, and the end surface of the support rod 7.1 is provided with a cone that cooperates with the connection block a9 Shaped groove 14.

Embodiment 3

[0025] This embodiment improves on the basis of Embodiment 1:

[0026] The wire mechanism 15 includes a sleeve 15.2 sleeved on the hollow pillar 5, the sleeve 15.2 is provided with a wire port 15.3 corresponding to the opening 6, and the outer wall of the sleeve 15.2 is provided with guide wheels 15.1 on both sides of the wire port 15.3. The cylinder 15.2 cooperates with the hollow pillar 5 through the lifting mechanism 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com