Calibrating device for soft magnetic stripe

A technology of a correction device and a magnetic strip, applied in the field of correction devices, can solve the problems of affecting the production of magnetic penetration, poor magnetic penetration effect, etc., and achieve the effects of good linear parallelism, good magnetic penetration effect and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

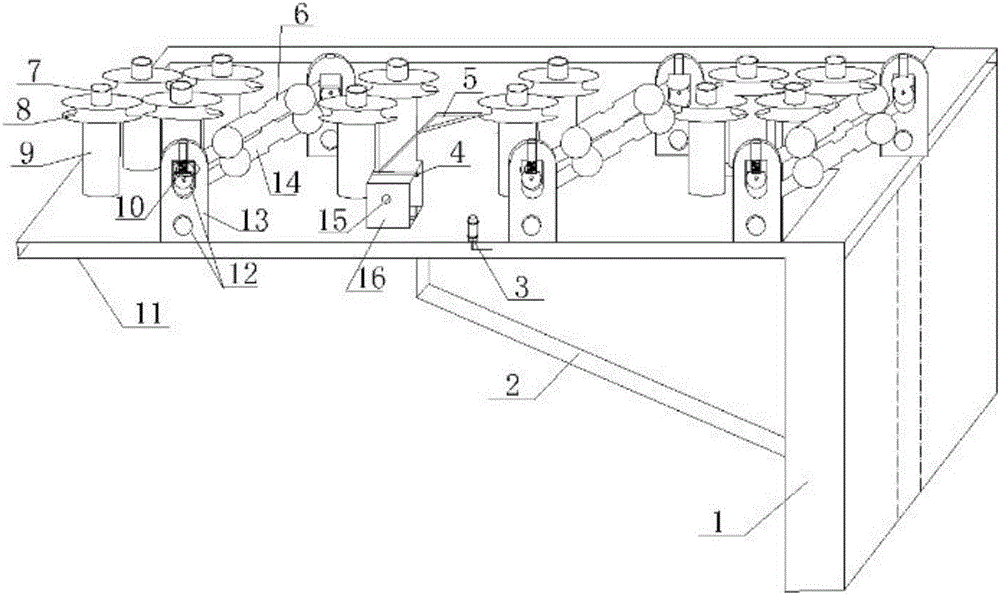

[0015] Referring to the accompanying drawings, a soft magnetic strip correction device is characterized in that it includes a bottom support device, a longitudinal leveling device, a horizontal correction assembly, a transition flat support and an induction corrector. The bottom support device includes a side support plate 1 , trapezoidal support plate 2 and horizontal base support 11, described longitudinal leveling device comprises vertical support plate 13, lower roller 14, upper roller 6, pin shaft 12 and stage clip adjustment assembly 10, and longitudinal leveling device has three groups, so The horizontal correction assembly includes support columns 9, rollers 8, gaskets and bolts 7. There are twelve horizontal correction assemblies and six groups. The transition flat supports include positioning seats 16, fixed bolts 4, flat supports 5 and pins 15, The induction corrector 3 is installed and fixed below the horizontal base 11, and the center line of the induction correcto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com