Automatic production process system for standard part

A technology of production process and standard parts, which is applied in the field of automatic production process system of standard parts and plate production system, can solve the problems of low production efficiency per capita, achieve the goal of increasing market share and brand effect, improving production efficiency and saving production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

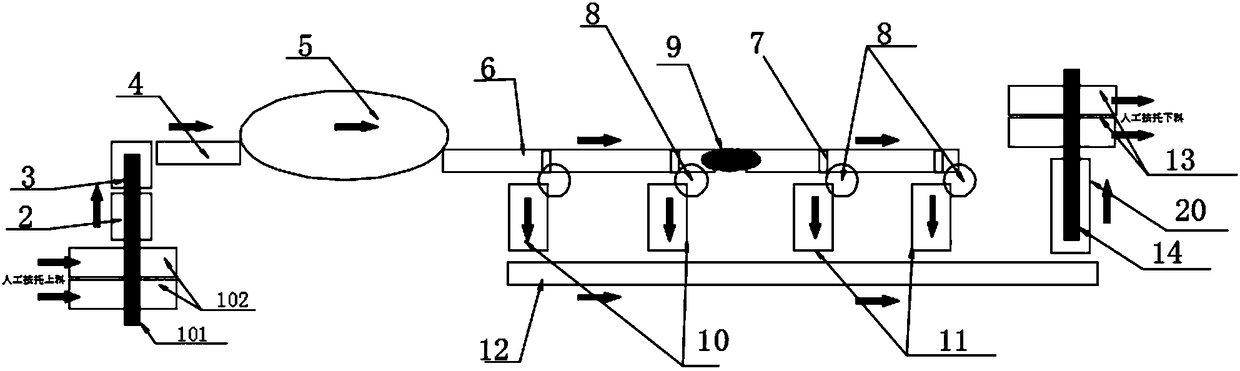

[0023] The invention is illustrated below in conjunction with the accompanying drawings. The following positional relationships are relative positional relationships in the accompanying drawings, and the technical solution is not specifically limited.

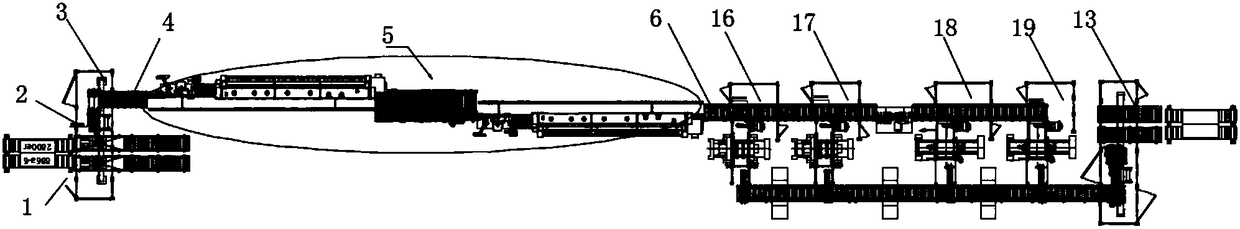

[0024] Such as figure 1 As shown, an automatic production process system for standard parts includes a feeding device 1, a board splitter 2, a motion steering device 3, an edge conveyor 4, a left and right edge banding machine 5, a main conveying line 6, and a main conveying line 6 The multiple processing stations on the side are respectively station one 16, station two 17, station three 18 and station four 19;

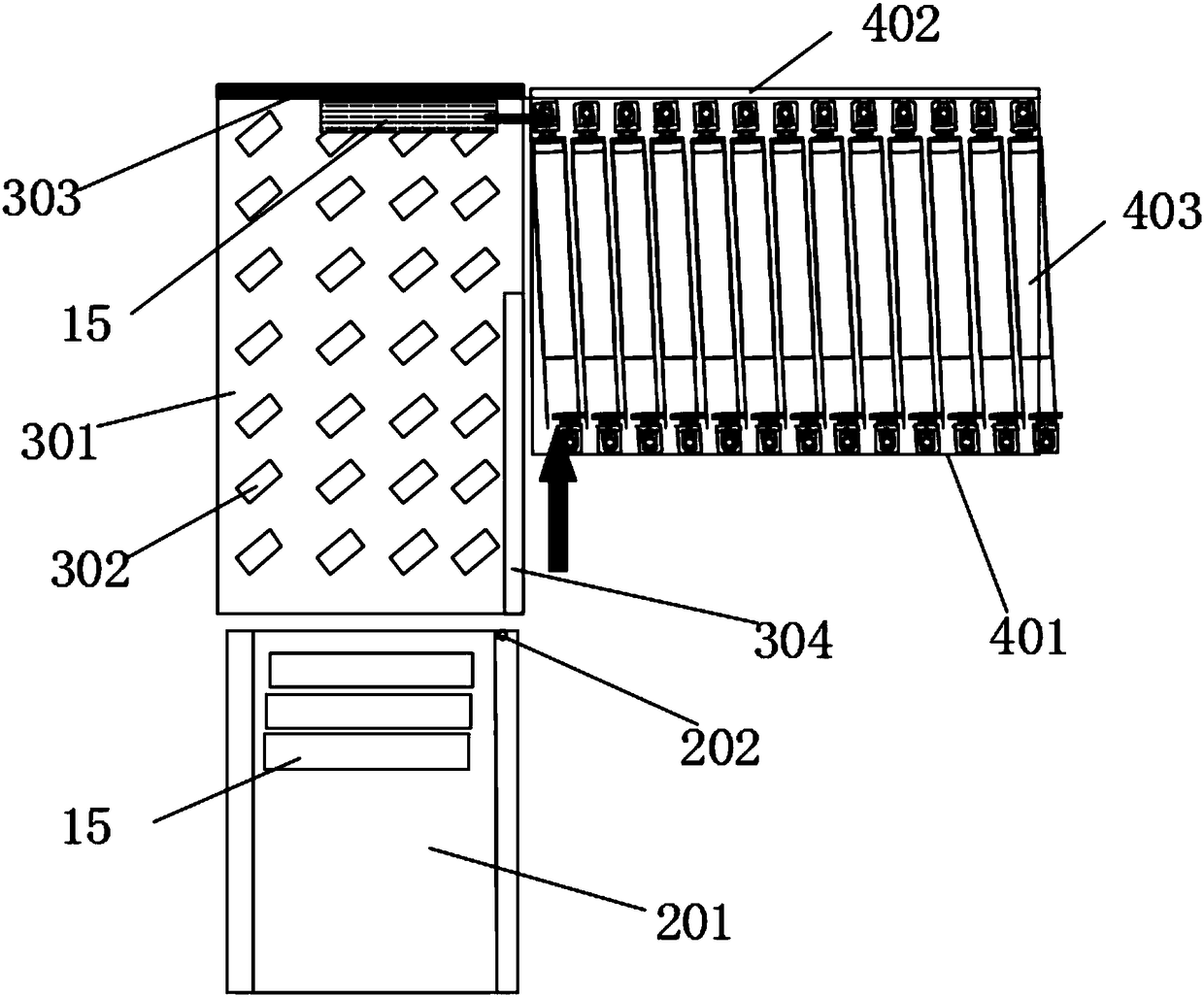

[0025] The feeding device 1 is used to simultaneously feed a plurality of standard panels 15 on the splitter 2, the feeding device 1 includes a feeding station 102 and a feeding manipulator, and the feeding station 102 is provided with a storage rack, the standard plate 15 to be processed is stored in the storage rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com