Water film adsorption solid-phase particle type dust-free grinder

A solid-phase particle and grinder technology, which is applied to portable grinding machines, grinding machines, grinding/polishing equipment, etc., can solve the problems of workers inhaling a lot of dust, small operating radius, and low efficiency, and achieve high market promotion value and reduce Human body damage, functional and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

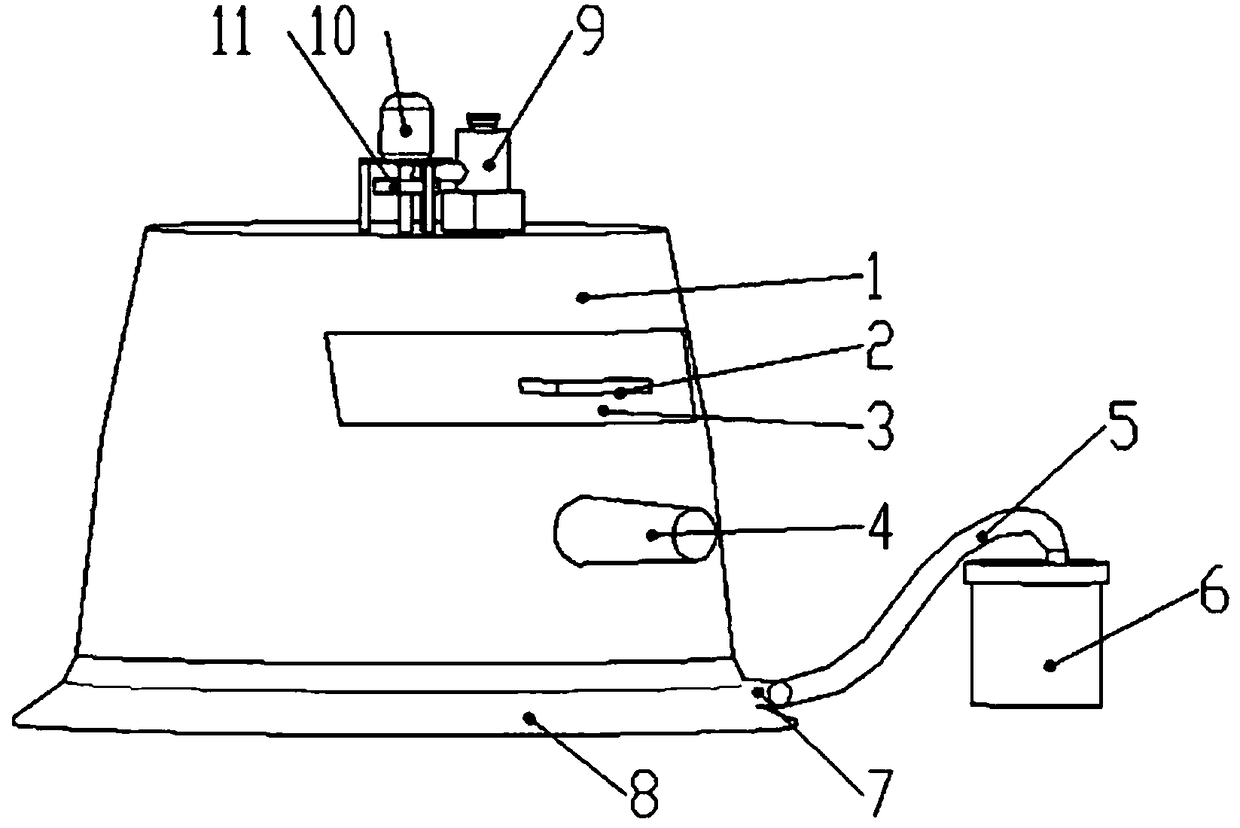

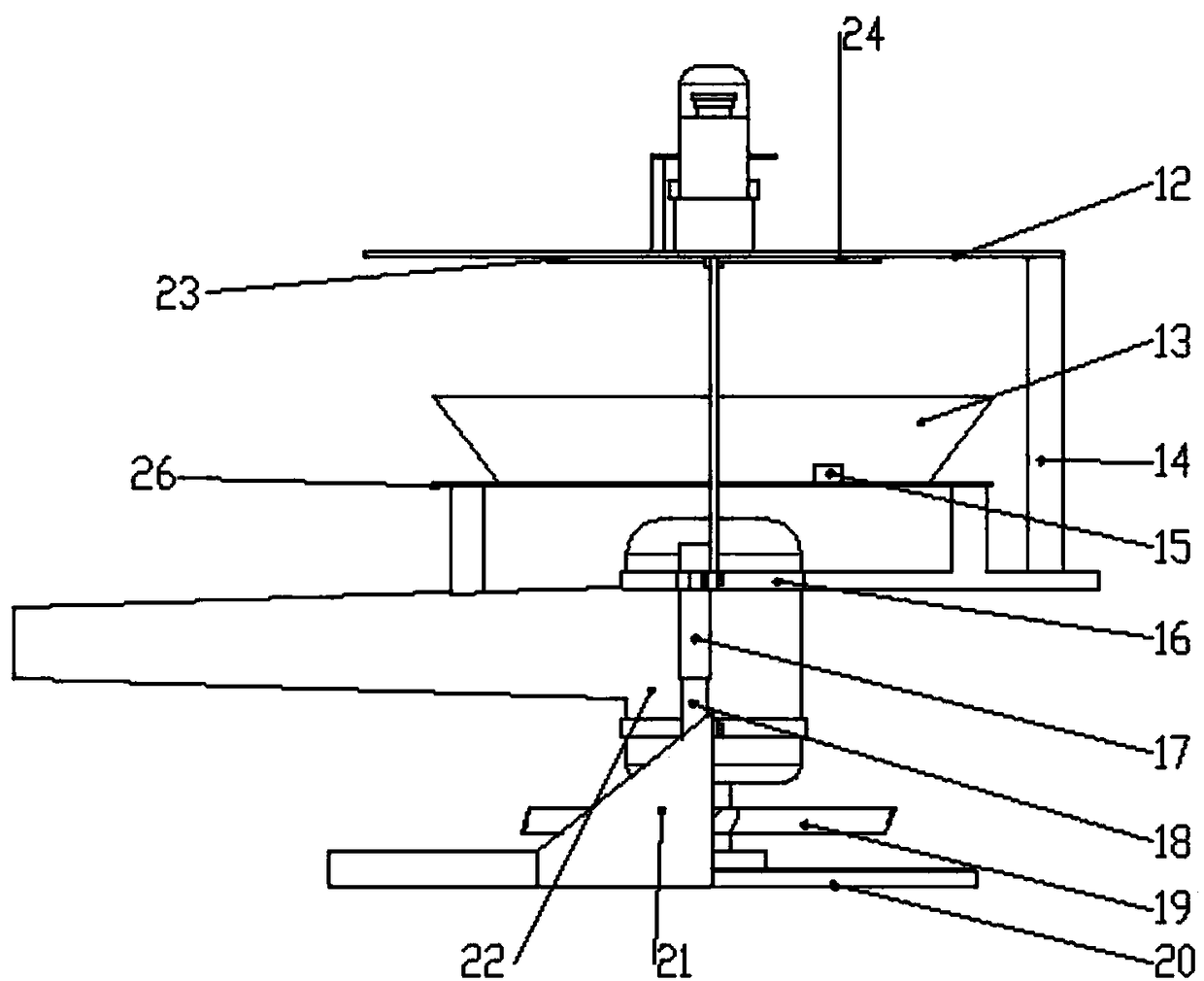

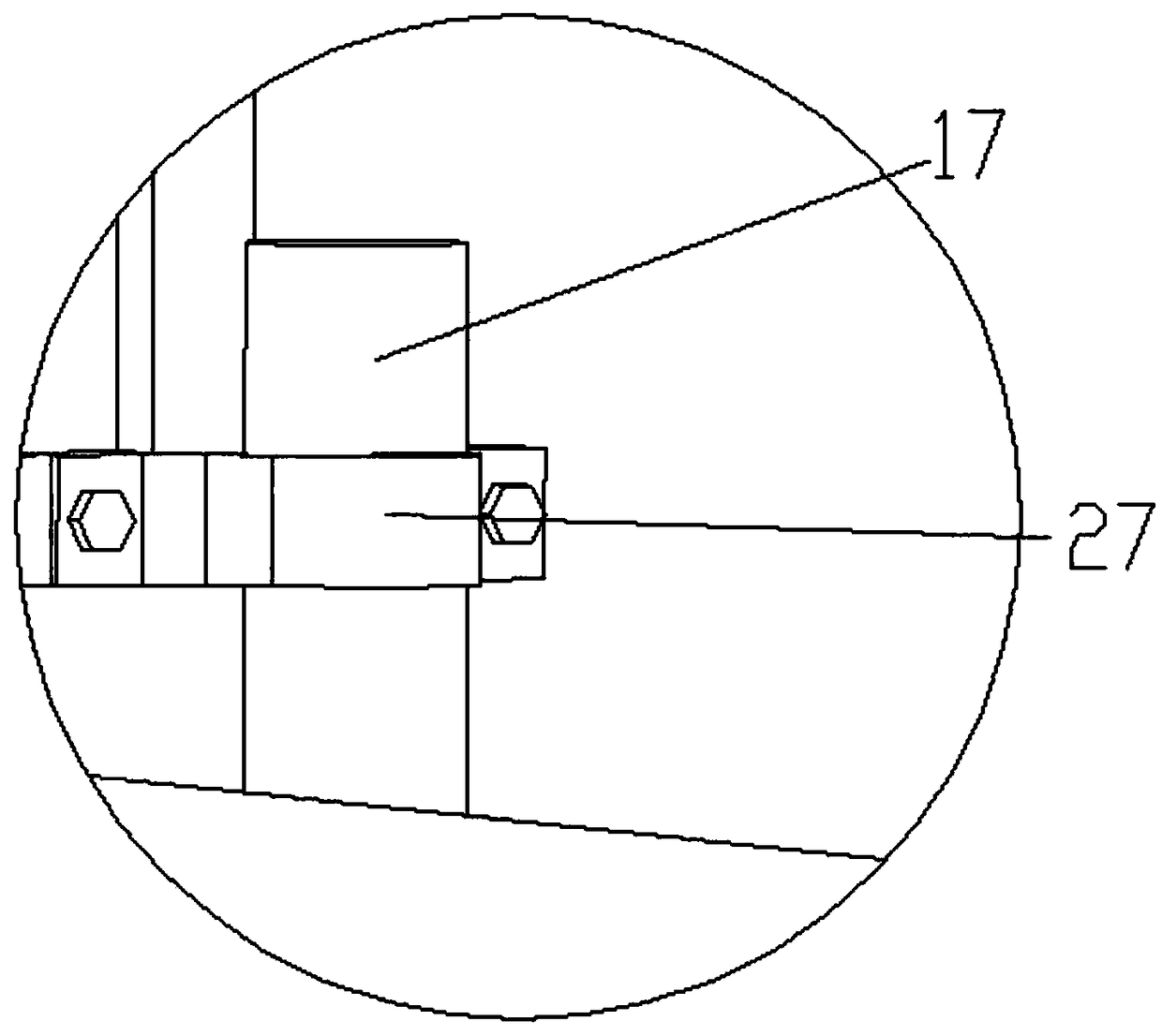

[0031] See attached Figure 1-11 , the water film adsorption solid phase particle type dust-free grinder provided by the present invention mainly includes a handle 4, a grinding wheel 20 and a grinding motor 22; 28 is fixed; the fan 19 is fixed on the motor shaft between the cutting motor 22 and the grinding wheel 20, and the solid phase particles are blown and rotated; the iron hoop 16 with a cross bar is fixed above the cutting motor 22, On the cross bar of the iron hoop 16 with a cross bar, an upper fixed cylinder 17 is fixed by an iron hoop 27; the upper end of the upper fixed cylinder 17, which is threaded with the fly dust collection cylinder 21 through a clearance fit, is provided with a lower ring platform. Telescopic rod 18 cooperates, telescopic spring 25 is installed between upper fixed cylinder 17 and lower telescopic rod 18, and ring cover 39 fixes lower telescopic rod 18 on the upper fixed cylinder 17 by threading with upper fixed cylinder 17, this structure It ...

Embodiment 2

[0033] On the basis of Embodiment 1, the front end of the tray 26 in this embodiment is provided with two limit blocks 15, which are used to limit the position of the dust collection tank 13, which is convenient for placement. When it is put in, it is directly pushed to the bottom. for the correct position.

Embodiment 3

[0035] On the basis of Embodiment 2, the bottom of the housing 1 described in this embodiment is fixed with a soft edge 8 by bonding, which can ensure that the housing 1 can be attached to the working surface in real time, and can effectively prevent flying dust from Fly out from the gap between the working surface and the housing 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com