Water mist fan and water mist condensation system

A water mist fan and fan technology, which is applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators, can solve the problems of unsatisfactory condensation and adsorption effects of water mist nozzles, and achieve obvious condensation and adsorption effects. The effect of large, simple rotating structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

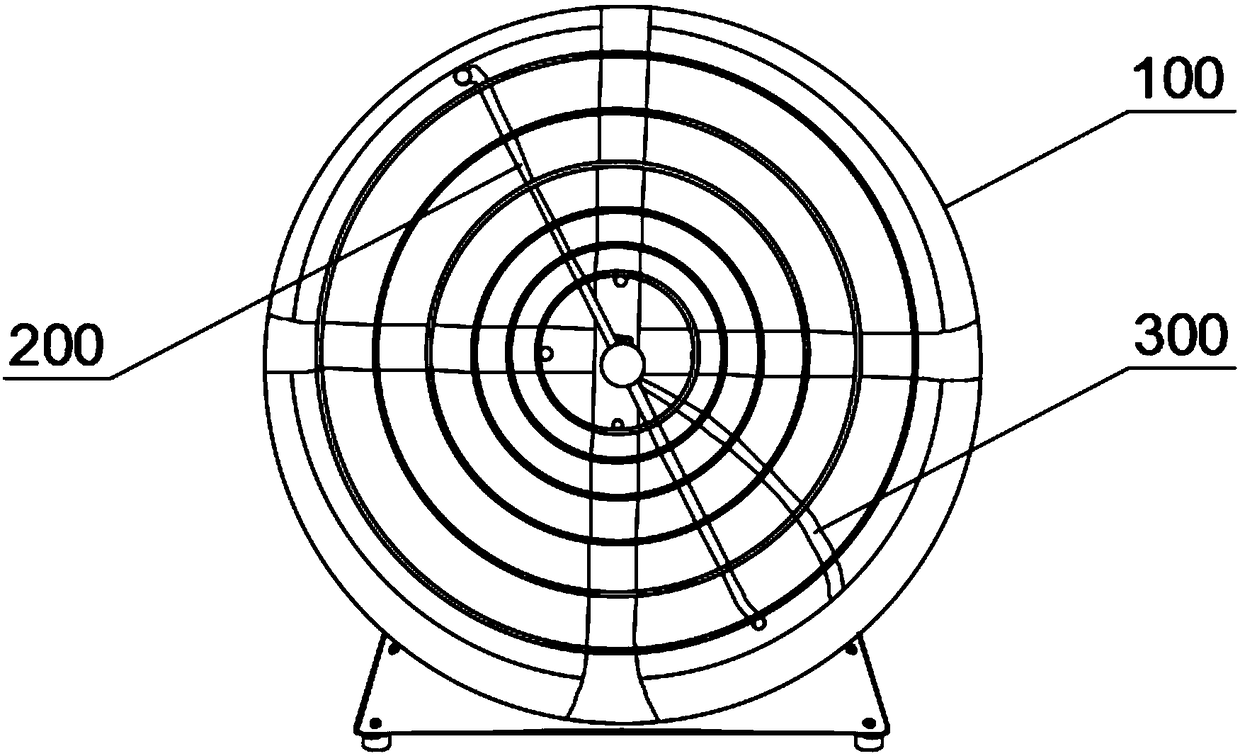

[0044] In the optional scheme of this embodiment, such as figure 1 , figure 2 As shown, a water mist fan provided in this embodiment includes a fan cover 100, a rotating nozzle 200 and a water inlet pipe 300; one end of the water inlet pipe 300 is arranged in the middle of the fan cover 100, and the other end of the water inlet pipe 300 is used A high-pressure water mist fire extinguishing device; the rotating nozzle 200 is fixedly rotated and arranged in the middle of the fan cover 100 ; the rotating nozzle 200 communicates with the water inlet pipe 300 .

[0045] In this embodiment, one end of the water inlet pipe 300 is arranged in the middle of the fan cover 100, the other end of the water inlet pipe 300 is connected to a high-pressure water mist fire extinguishing device, and the rotating nozzle 200 arranged in the middle of the fan cover 100 is connected to the inlet by fixed axis rotation. The water pipe 300 is connected; after the high-pressure water mist fire exting...

Embodiment 2

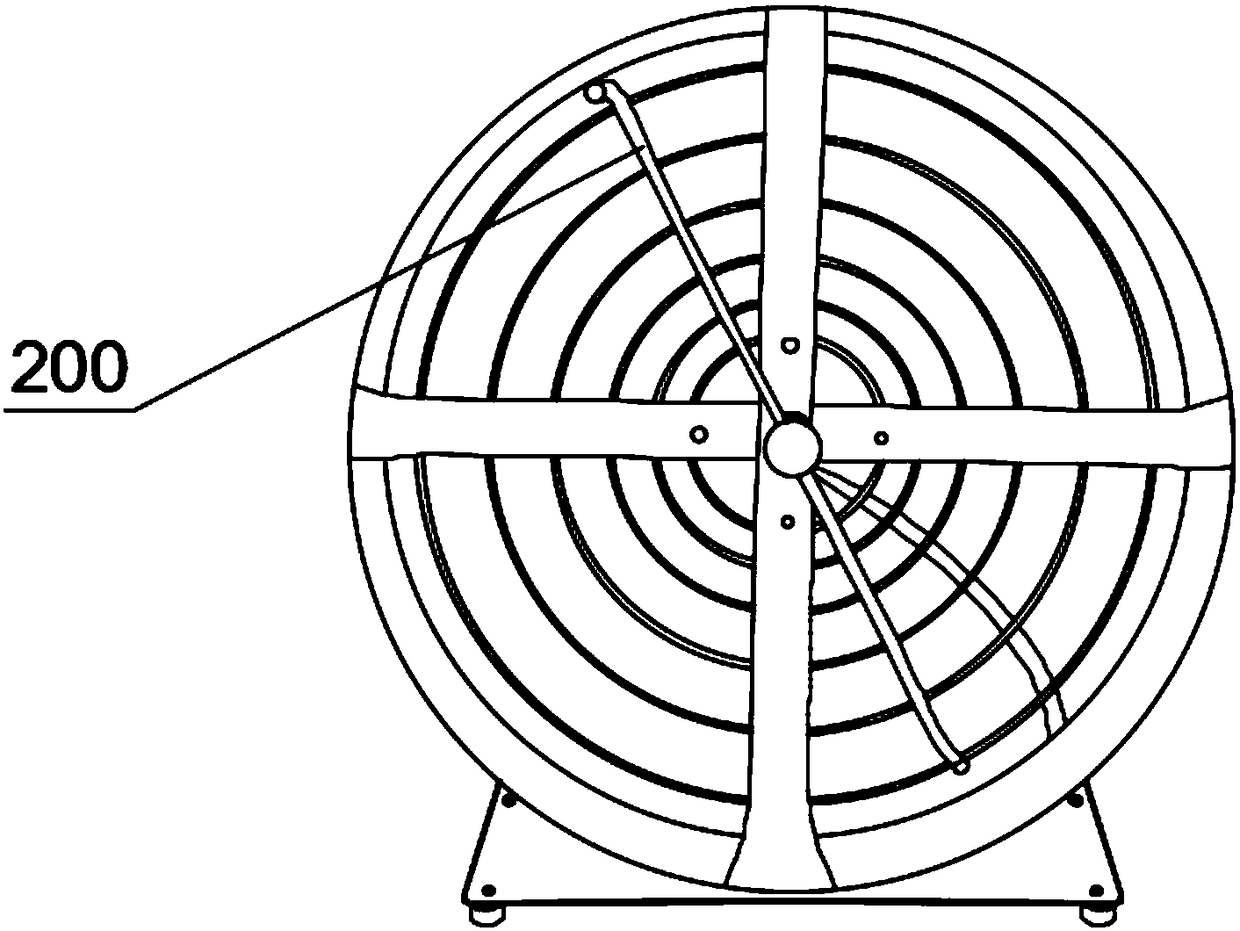

[0072] In the optional solution of this embodiment, different from the first embodiment, the number of rotating nozzles 200 is more than 2; more than 2 rotating nozzles 200 are arranged inside the fan casing 100 at the same interval along the circumferential direction of the fan casing 100 .

[0073] In this embodiment, more than two rotating nozzles 200 are evenly arranged along the circumferential direction of the fan cover 100 to jointly spray.

[0074] In this embodiment, two or more rotating nozzles 200 spray together, so that the density of the sprayed high-pressure fine water mist jet is higher, and the condensation and adsorption effects are more obvious.

[0075] In the optional solution of this embodiment, the middle part of the fan cover 100 is provided with a hollow shaft and a hollow fixed shaft; the hollow shaft is arranged in the hollow fixed shaft; the water inlet pipe 300 is arranged on the hollow fixed shaft; Fixedly connected, the rotating nozzle 200 rotates...

Embodiment 3

[0080] In an optional solution of this embodiment, a water mist condensation system provided by this embodiment includes the water mist fan as described in Embodiment 1 or Embodiment 2.

[0081] In this embodiment, the high-pressure plunger pump on the high-pressure water mist fire extinguishing device provides water sources for multiple water mist fans, and multiple water mist fans are used in combination according to actual needs to form a multi-layer condensation barrier to maximize the condensation of toxic Harmful gas and dust absorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com