Preparation method for extract of total flavonoids in kernel of Prinsepia utilis

A technology of green thorn nuts and total flavonoids, applied in the field of extraction, can solve the problems of application limitations, inconvenient recycling of macroporous resins, time-consuming and laborious separation and purification, etc., and achieve the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

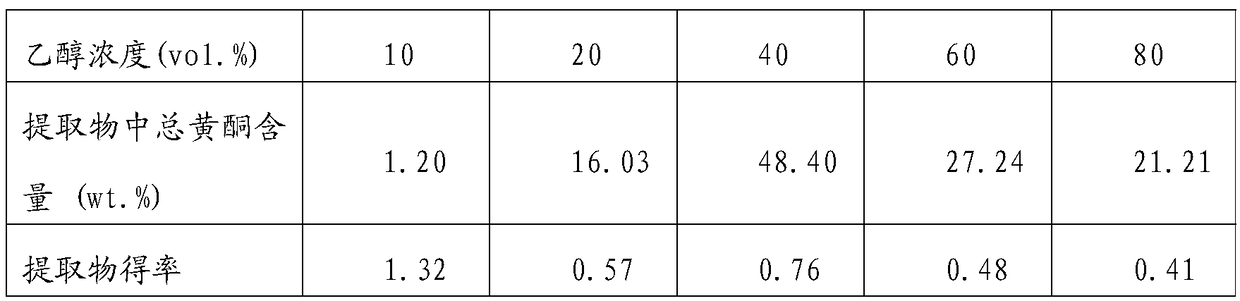

[0032] The preparation method of the total flavonoids extract of green thorn nuts of the present invention comprises the following steps: a degreasing step, a reflux extraction step and a separation and purification step.

[0033] Degreasing steps:

[0034] In the preparation method of the total flavonoids extract of green thorn nuts of the present invention, a degreasing step is added before the reflux extraction step, so as to shorten the time of the separation and purification step, increase the content of total flavonoids in the extract and improve the efficiency. The degreasing step is based on the total oil yield as the final measure of the degreasing effect, and the best process conditions are selected.

[0035] According to the weight ratio of material to liquid of 1:3 to 1:8, the dried and crushed green thorn nuts are soaked in the degreasing agent, and the degreasing is carried out at room temperature for 1 to 3 times, and soaking is carried out during each degreasin...

Embodiment 1

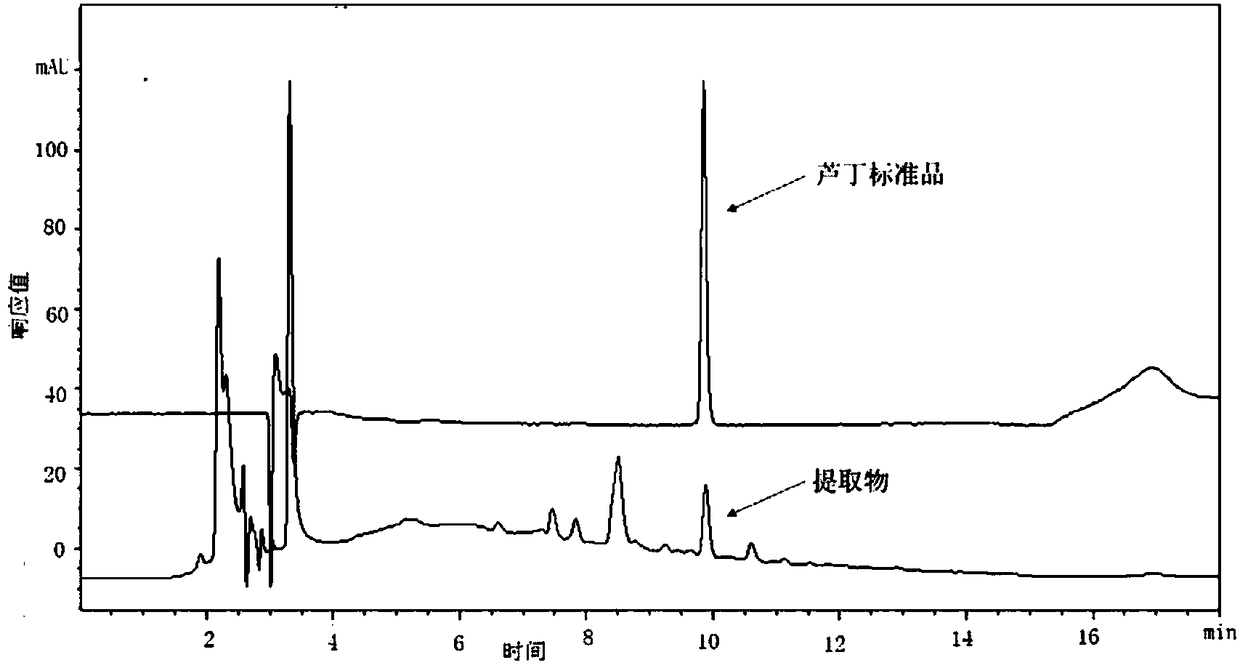

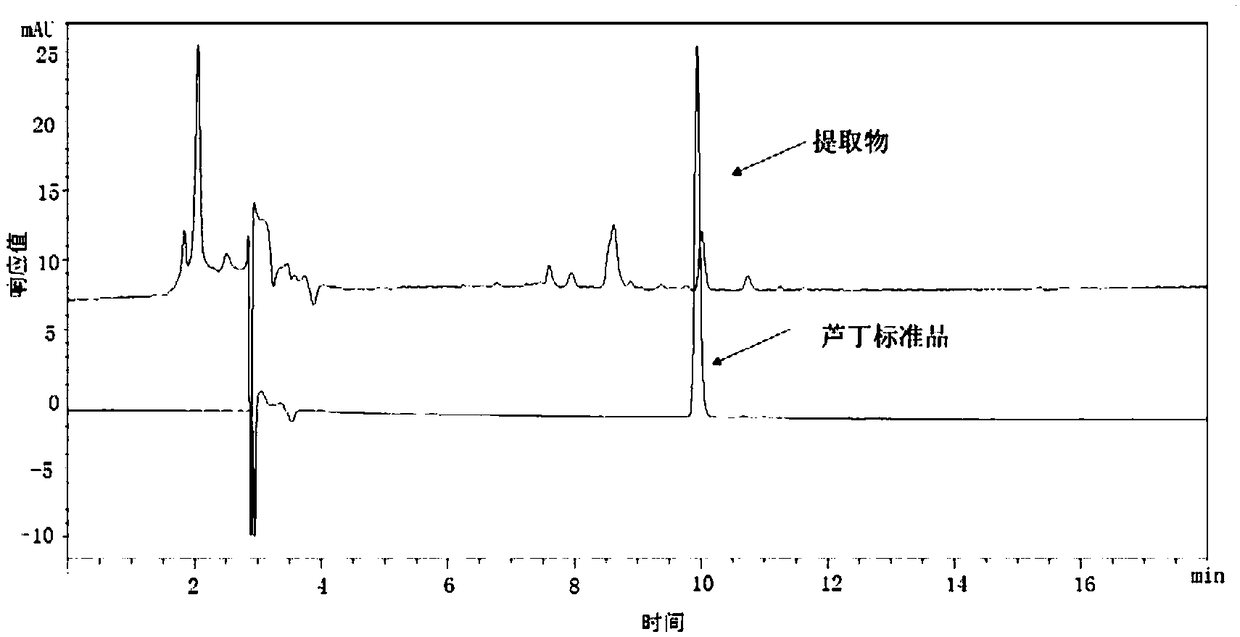

[0048] Take 200 g of dried green thorn nuts, crush them, and degrease them with 600 mL of n-hexane for 3 times. During each degreasing process, soak and stir for 3 hours each time to obtain green thorn nut materials. Afterwards, the green thorn nut material was added into an ethanol aqueous solution with a volume concentration of 70vol.% at a ratio of 1:8 by weight ratio of solid to liquid, and refluxed and extracted twice at 75°C, and the two extracts were combined and enriched by filtration , then remove the ethanol in the extract by concentrating under reduced pressure to obtain a concentrated solution, then evaporate the concentrated solution to dryness in a water bath to obtain 16.23 g of crude extract, and take rutin as a standard contrast, and the total flavonoid content in this crude extract is 20.99wt .%.

Embodiment 2

[0050] Take 200 g of dried green thorn nuts, crush them, and degrease them with 600 mL of petroleum ether for 3 times. During each degreasing process, soak and stir for 3 hours each time to obtain green thorn nut materials. Afterwards, the green thorn nut material was added into an ethanol aqueous solution with a volume concentration of 70vol.% at a ratio of 1:8 by weight ratio of solid to liquid, and extracted twice under reflux at 75°C, and the two extracts were combined and enriched by filtration. Then, the ethanol in the extract was removed by concentration under reduced pressure to obtain a concentrated solution, and then the concentrated solution was evaporated to dryness in a water bath to obtain 15.87 g of crude extract. Taking rutin as a standard contrast, the total flavonoid content in this crude extract was 18.79wt. %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com