Automatic production line for mobile phone screen testing

An automated production line, mobile phone screen technology, applied in the direction of telephone communication, electrical components, branch equipment, etc., can solve the problems of multiple productivity and capital investment, low degree of automation, long detection time, etc., to reduce labor costs, reduce labor intensity, The effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

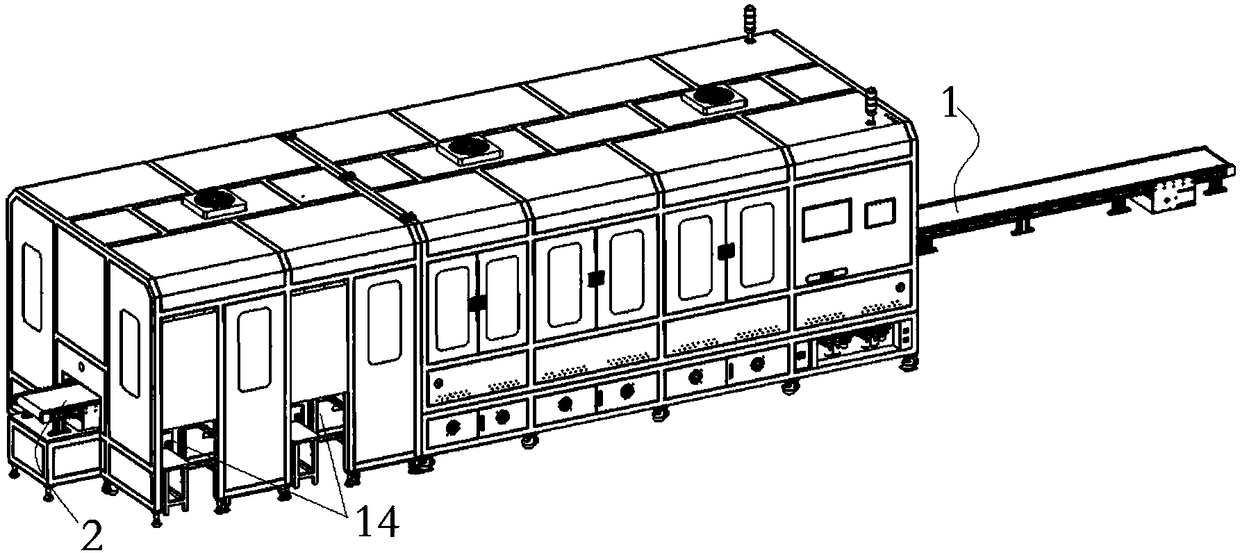

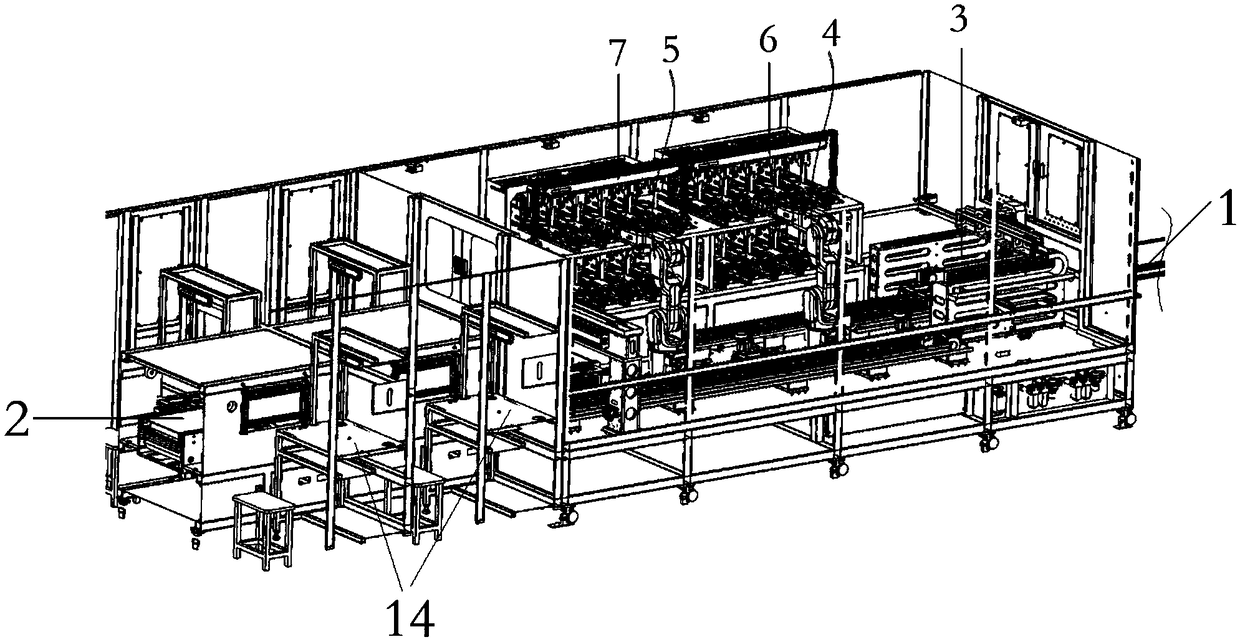

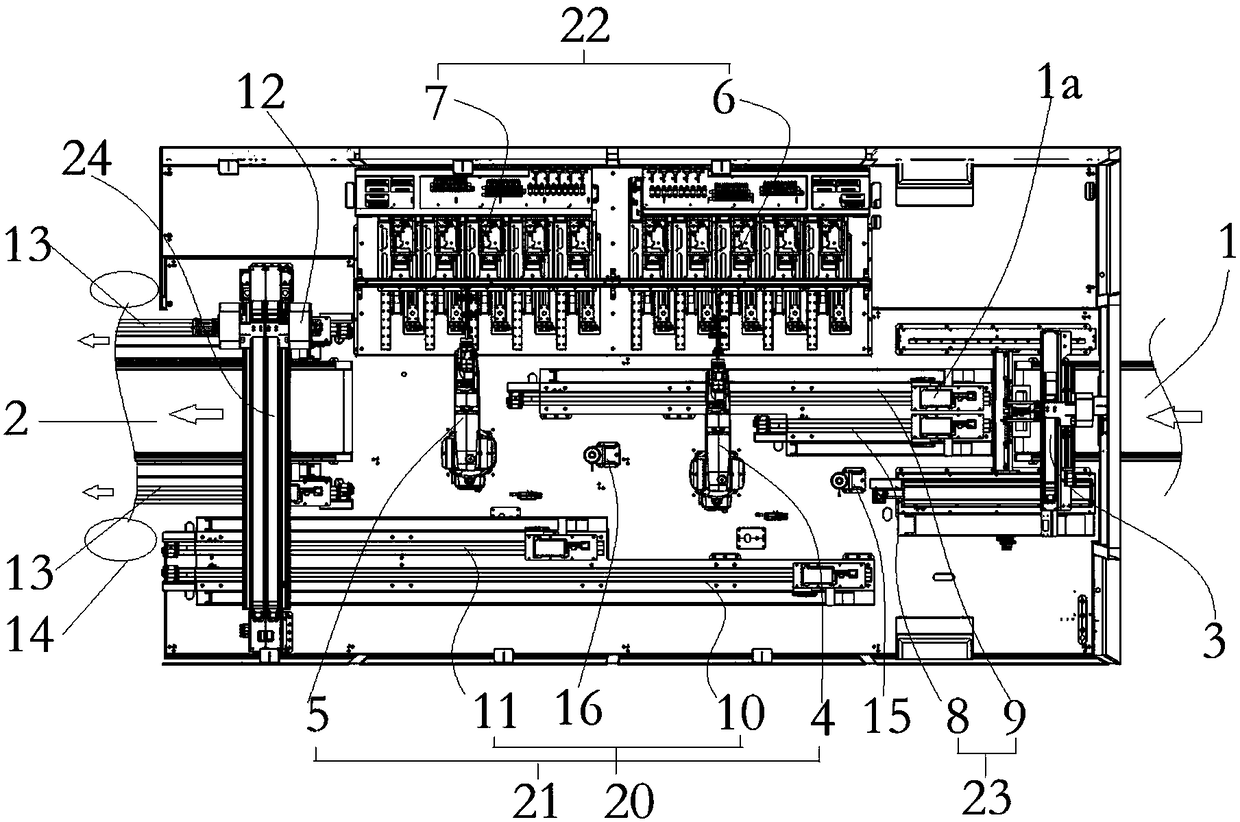

[0040] as attached figure 1 To attach Figure 6 As shown, an automated production line for mobile phone screen testing includes a material input mechanism 1, a feeding and grabbing device 3, a feeding and conveying device 23, a handling manipulator device 21, a screen detection device 22, a transfer and output conveying device 20, a transfer Device 12, re-inspection conveying device 13 and material output mechanism 2;

[0041]The feeding end of the feeding conveying device 23 is arranged correspondingly to the discharging end of the material input mechanism 1, and the described material feeding grabbing device 3 is arranged above the discharging end of the material input mechanism 1, and the material input mechanism is a belt Conveyor, the material input mechanism 1 conveys material to the feeding conveying device 23 through the feeding grasping device 3, the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com