Preparation method and application of modified sodium vanadium fluorophosphate positive electrode material

A technology of sodium vanadium fluorophosphate and positive electrode materials, applied in the field of electrochemistry, can solve the problems of inability to achieve direct contact, trouble, and complete coating of positive electrode materials, etc., to achieve reduced synthesis costs, short process, and excellent cycle stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

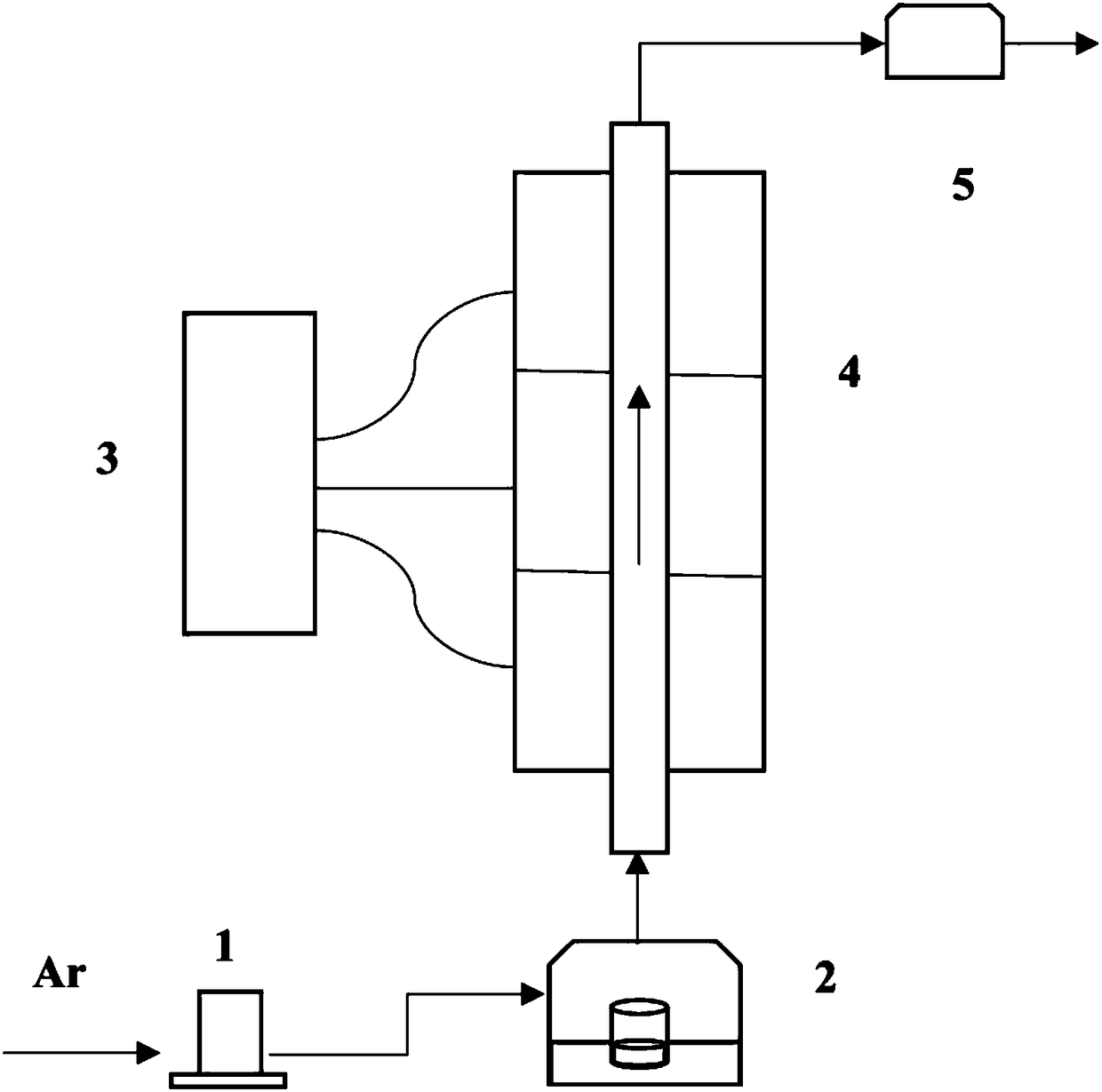

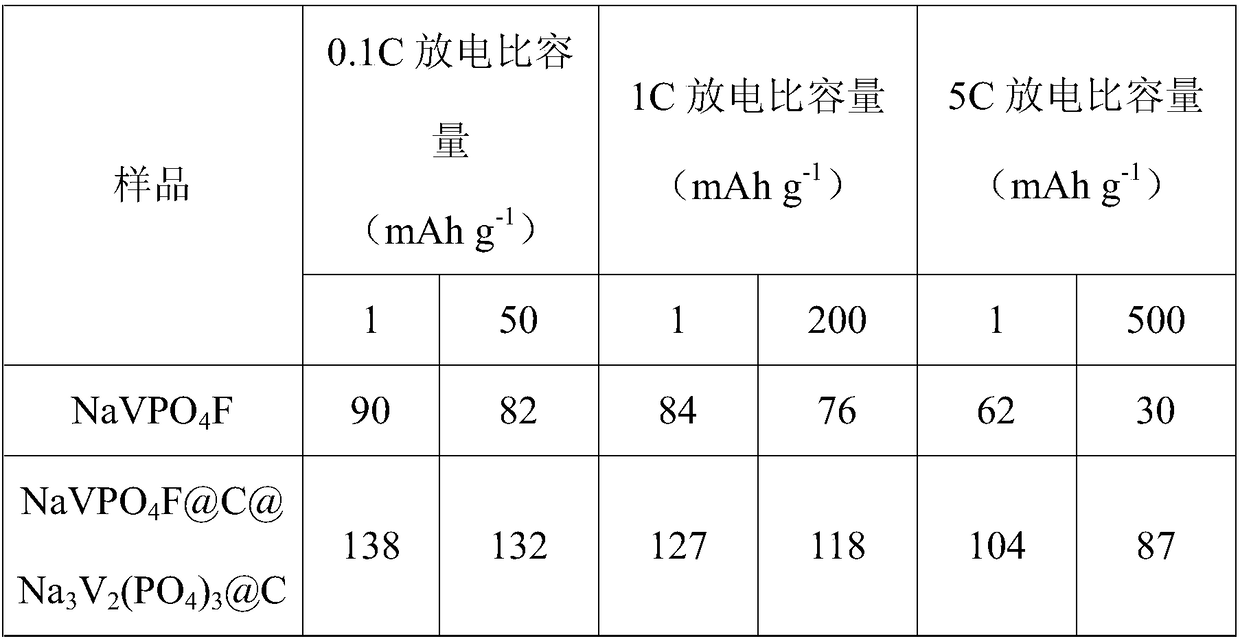

[0049] Sodium fluoride, ammonium metavanadate, and ammonium dihydrogen phosphate are mixed according to the ratio of sodium, vanadium, phosphorus, and fluorine elements in a molar ratio of 1:1:1:1, and the molar ratio of ammonium metavanadate is 1:1. Oxalic acid (that is, the theoretical reaction amount), dissolved in deionized water, stirred at room temperature for 2 hours, prepared a uniform NaVPO 4 F precursor solution, ultrasonic atomization (1.7MHz±10%) to form microsphere droplets, carried by the carrier gas argon to pyrolyze it in an argon atmosphere at 600 °C, the carrier gas flow rate is 1L / min, to prepare NaVPO 4 F microspheres.

[0050] Sodium carbonate, ammonium metavanadate and ammonium dihydrogen phosphate are mixed and dissolved in water according to the molar ratio of sodium, vanadium and phosphorus in a ratio of 3:2:3, and oxalic acid (theoretical 3 times the value) mixed, stirred for 2h, the prepared NaVPO 4 F microspheres were added to it, after ultrasonic...

Embodiment 2

[0055] Mix sodium fluoride, ammonium metavanadate, and ammonium dihydrogen phosphate according to the ratio of sodium, vanadium, phosphorus, and fluorine elements in a molar ratio of 1:1:1:1, add oxalic acid (3 times the theoretical amount), dissolve In deionized water, stir at room temperature for 2 hours to prepare uniform NaVPO 4 F precursor solution, ultrasonic atomization (1.7MHz±10%) to form microsphere droplets, carried by the carrier gas argon to pyrolyze it in an argon atmosphere at 500 °C, the carrier gas flow rate is 1L / min, and NaVPO is prepared 4 F microspheres.

[0056] Sodium carbonate, ammonium metavanadate and ammonium dihydrogen phosphate are mixed and dissolved in water according to the molar ratio of sodium, vanadium and phosphorus in a ratio of 3:2:3, and oxalic acid (theoretical 3 times the value) mixed, stirred for 2h, the prepared NaVPO 4 F microspheres were added to it, after ultrasonic treatment at 40KHz for 2h, put it into 120°C and dry for 12h, th...

Embodiment 3

[0060] Mix sodium fluoride, ammonium metavanadate, and ammonium dihydrogen phosphate according to the ratio of sodium, vanadium, phosphorus, and fluorine elements in a molar ratio of 1:1:1:1, add oxalic acid (adding twice the theoretical amount), dissolve In deionized water, stir at room temperature for 2 hours to prepare uniform NaVPO 4 F precursor solution, ultrasonic atomization (1.7MHz ± 10%) to form microsphere droplets, carried by the carrier gas argon and pyrolyzed in an argon atmosphere at 600 °C, the carrier gas flow rate is 2L / min, and NaVPO is prepared 4 F microspheres.

[0061] Sodium carbonate, ammonium metavanadate and ammonium dihydrogen phosphate are mixed and dissolved in water according to the molar ratio of sodium, vanadium and phosphorus in a ratio of 3:2:3, and oxalic acid (theoretical 2 times the value) mixed, stirred for 2h, the prepared NaVPO 4 F microspheres were added to it, after ultrasonic treatment at 40KHz for 2h, it was placed in 120°C for 12h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com