Process gas temperature control method for loose resurgence roller

A temperature control method and a technology of loosening and regaining moisture, which is applied in the field of temperature control of loosening and dampening drum process gas and tobacco shred production process control. It can solve the problems of unsolved water addition and steam valve opening control hysteresis, and achieve stable loosening and regaining moisture. Process, easy design and implementation, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

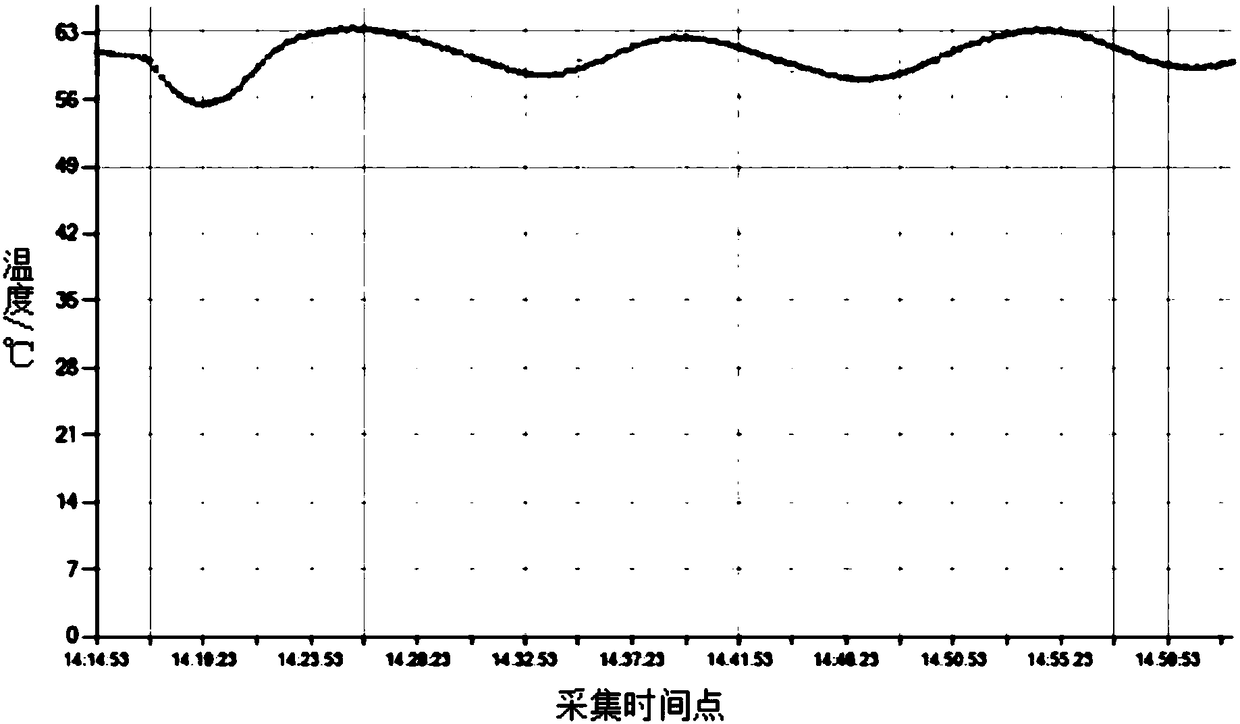

Image

Examples

Embodiment 1

[0025] In this example, the process requirements for the loosening and moisture regaining process of brand a product are: the temperature of the process gas is 70°C, and according to the equipment situation and process requirements, the T value of the collection period of water addition is set to 15 seconds, k 1 The value is 0.1.

[0026] set y 水 The range of upper and lower limits of compensation is -0.05~0.05, y 1 The range of y is 0~1, the range of y is 0~1, and the corresponding steam valve opening range is 0~100%.

[0027] The average water addition amount of the last batch of grade a calculated by this method is 200L / h, which is used as the standard value d of the water addition amount of the current batch.

[0028] The concrete steps of embodiment are as follows:

[0029] A: Set the formula parameters, that is, according to the requirements of the process standard, set the process gas temperature SP of the drum to 70°C, the standard value d of water addition to 200L / ...

Embodiment 2

[0036] When the next batch of grade a is produced, the standard value of water addition d is 204L / h.

[0037] When the real-time value of process gas temperature PV=72°C, the PID controller will output y in real time 1 = 0.62.

[0038] The instantaneous value of water addition d in the current cycle n = 200L / h, the amount of water added in the previous cycle d n-1=210L / h.

[0039] Calculate the current steam positioning valve opening y for compensation 水 =k*(d n -d n-1 ) / d=0.1*(200-210) / 204=-0.0049, which is the y used for compensation 水 =-0.0049, calculate the current steam valve opening setting value y=0.6151, output to the steam valve positioner, and the corresponding steam valve opening is 61.51%.

[0040] When entering the next cycle, when the real-time value of process gas temperature PV=71°C, the PID controller will output y in real time 1 = 0.615.

[0041] The instantaneous value of water addition d in the current cycle n =206L / h, the amount of water added in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com