A Kind of Trochoidal Milling Slotting Tool Path Generation Method

A trochoidal milling and slotting cutter technology, applied in the CAM field, can solve the problem of low trochoidal machining efficiency, and achieve the effects of reducing the total length, reducing load impact and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0040] Such as Figure 1-7 shown.

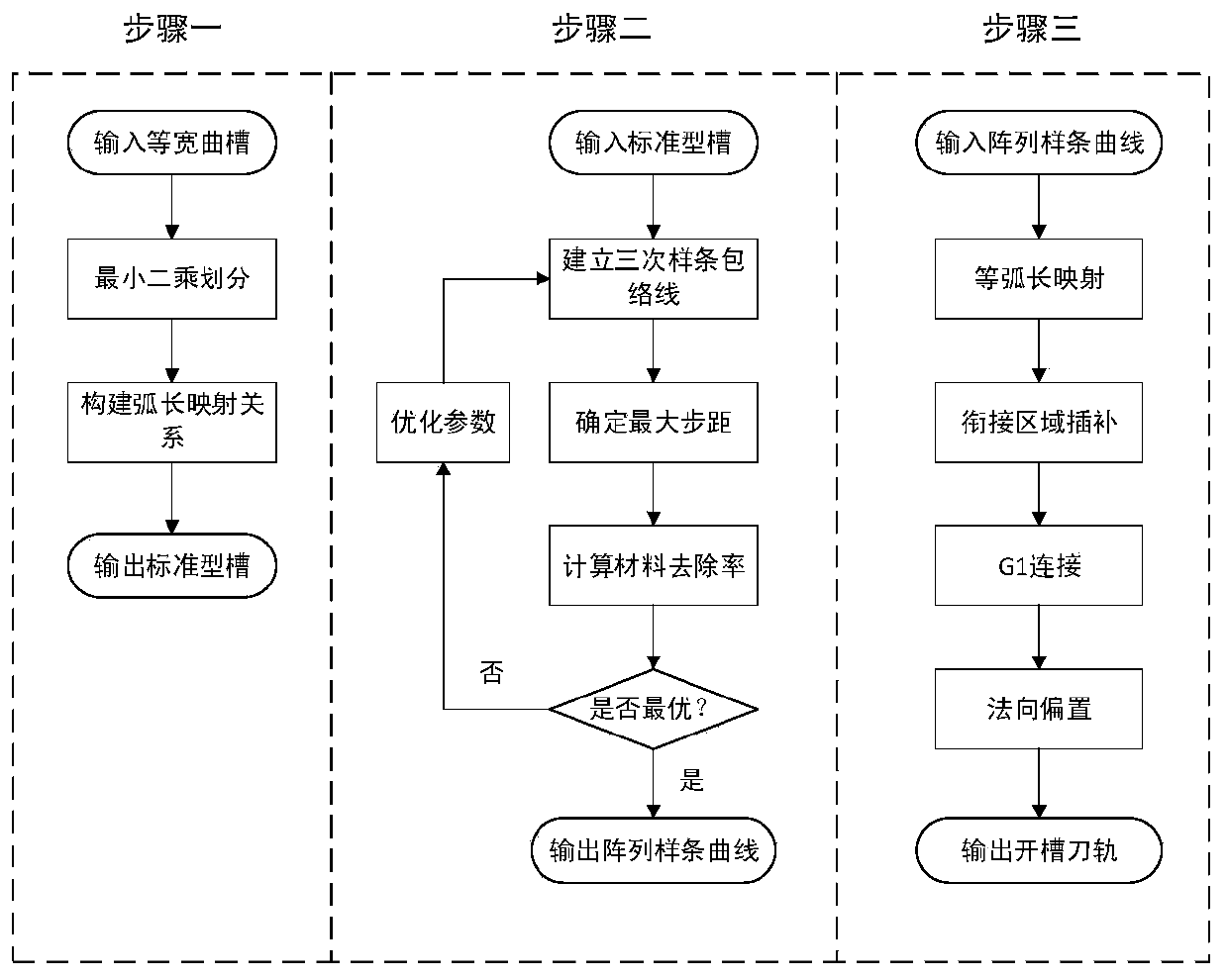

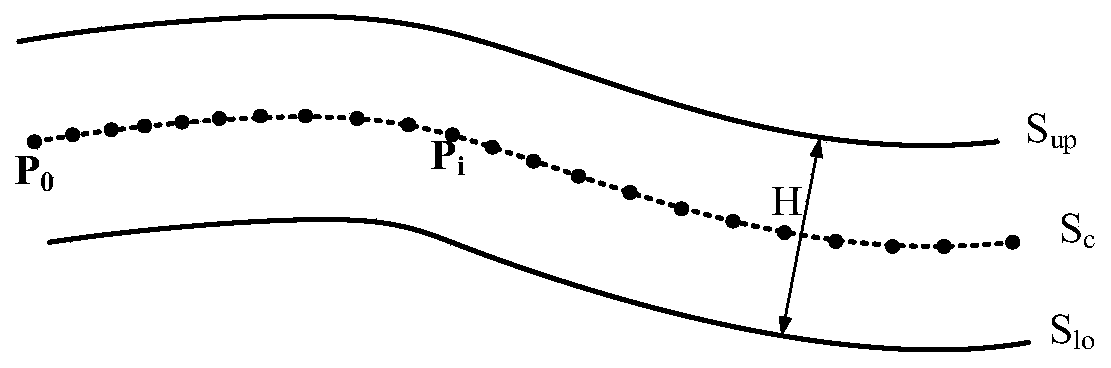

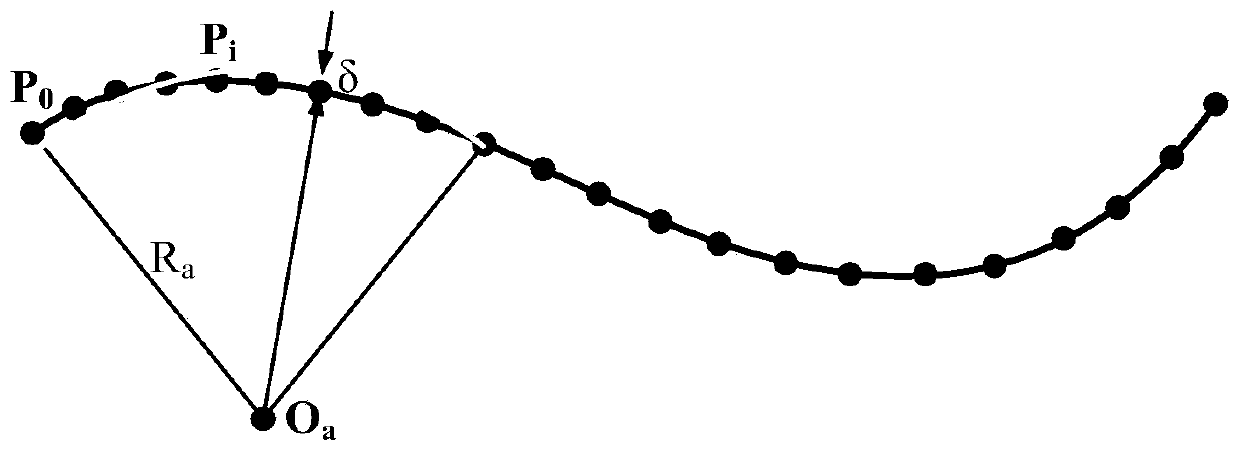

[0041] A trochoidal milling grooving tool path and a method for generating the same are applicable to grooving processing of equal-width curved grooves. The key is to first divide the equal-width curved groove into several equal-curvature circular grooves and straight grooves by using circular arc least square fitting, and establish the arc length mapping relationship; then, for the equal-curvature circular groove and straight groove standard The cubic spline curve is used to characterize the material boundary line formed by the tool motion envelope, the maximum step distance is determined according to the tool contact angle constraint, and the cubic spline curve is optimized with the material removal rate as the target, and an equidistant array is generated on the standard groove ;Map the array of material boundary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com