Long seal pasting device and processing box assembling production line

A technology of sealing parts and sticking positions, which is applied in the field of sticking long sealing parts and processing box assembly production lines, can solve the problems of lower assembly qualification rate, low production efficiency and large deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is an example of the process cartridge assembly line of the present invention, which also includes a specific description of the implementation of the sticky-length seal device on the sticky-length seal station.

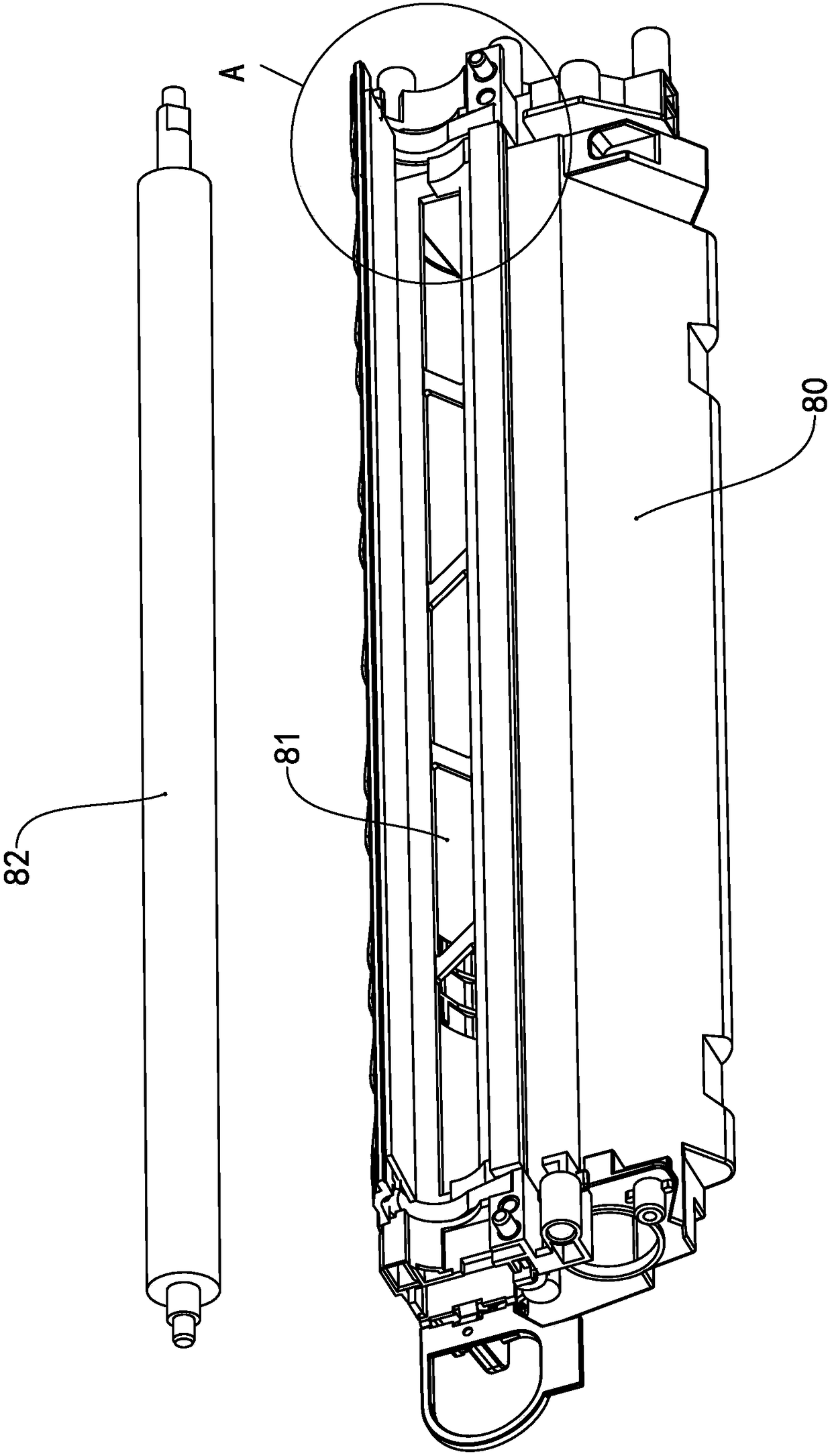

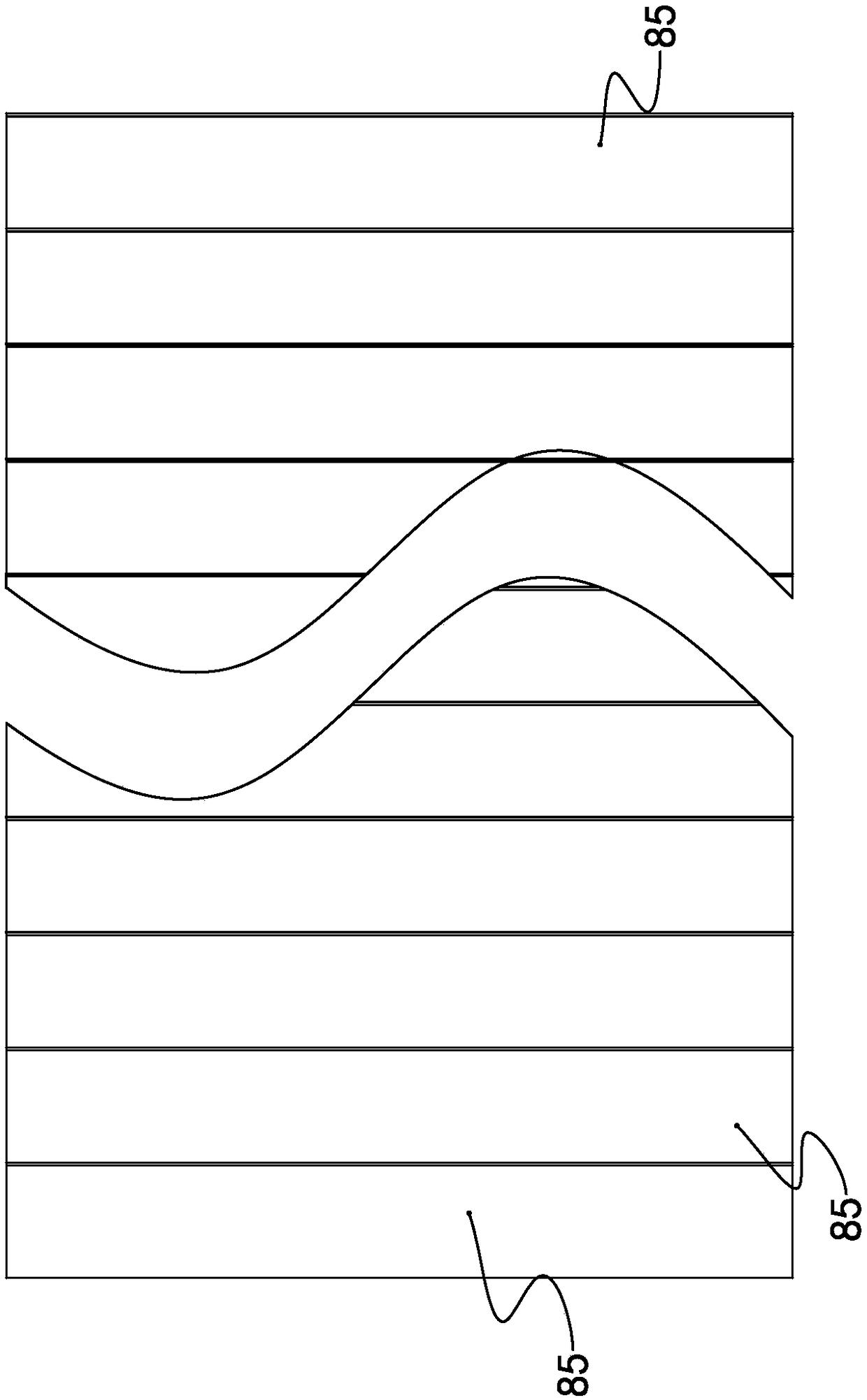

[0045] see Figure 5 , Figure 6 , Figure 7 , Figure 8 , for the sake of clarity, the process box assembly line omits some parts irrelevant to the present invention, and due to the limitation of the drawing, Figure 5 , Figure 6 is the entirety of an embodiment of the process cartridge assembly line, and Figure 7 , Figure 8 It is a plan view of the whole embodiment of the process cartridge assembly line.

[0046] On the base frame 1000 arranged in a straight line, there are workpiece raw material conveyor belt 100, loading station 200, end seal attaching station 300, side seal attaching station 400, and long seal attaching station arranged sequentially from left to right. 500 stations, 600 stations for sealing scrapers, 700 stations f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com