Cylinder block and compressor

A cylinder block and compressor technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of the motor stator gap value not being too small, limiting the energy efficiency of the compressor, and the rotor scavenging, etc. The effect of reducing consumption, reducing equipment costs and increasing energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

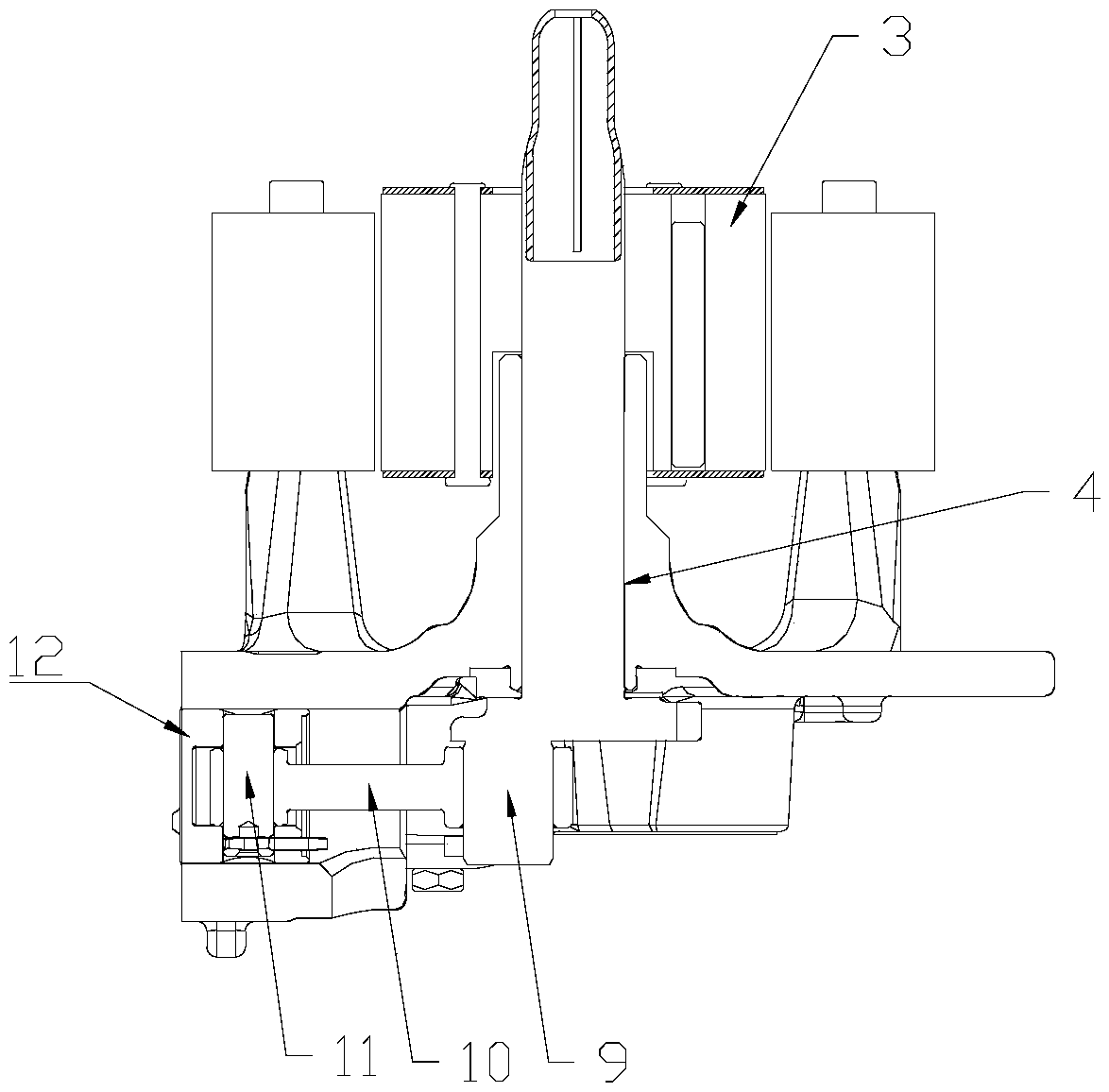

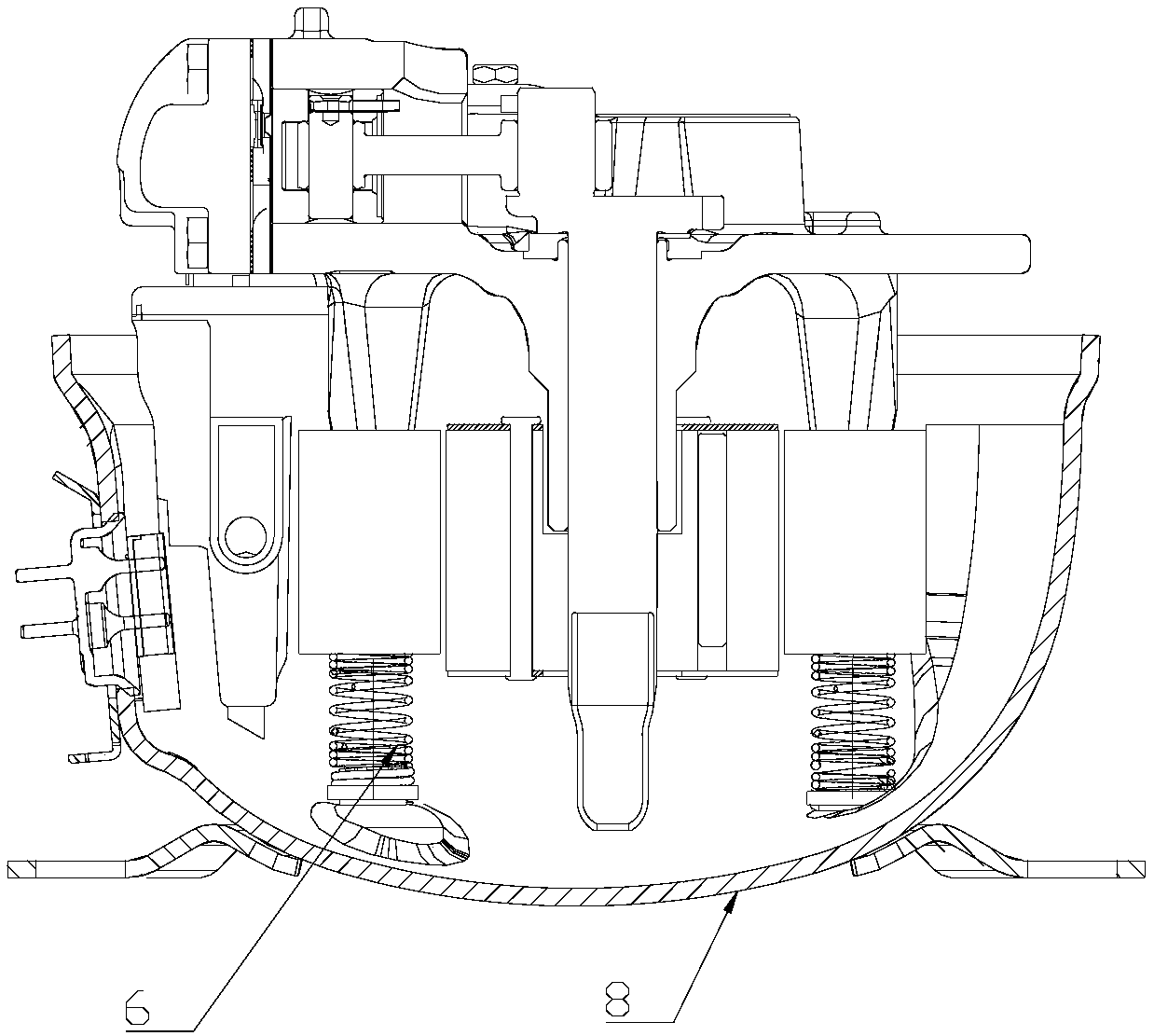

[0029] see in conjunction Figure 1 to Figure 3 As shown, a cylinder block according to an embodiment of the present invention includes:

[0030] Cylinder seat body 1;

[0031] The stator core 2 is integrally formed with the cylinder block body 1 .

[0032] The cylinder block of the present invention solves the problem of low assembly precision between the cylinder block and the stator core 2, and restricts the design of the gap value between the stator core 2 and the motor rotor 3, and the cylinder block main body 1 and the stator core 2 are integrally formed, reducing parts Quantity, the cylinder seat does not need to be machined to assemble the mounting surface, and there is only one machining error. The motor using this type of cylinder seat has higher installation accuracy, and the gap between the stator and the rotor can be designed to be smaller, without worrying that the stator and the rotor cannot Assembling or the problem of stator and rotor sweeping occurs, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com