Vertical rod supporting seat movably adjusted on overhung I-shaped steel and construction method of vertical rod supporting seat

A technology of mobile adjustment and I-beam, which is applied to the accessories of scaffolding, house structure support, house structure support, etc., can solve the problems of non-reuse, waste of manpower and material resources, damage to I-beam, etc., and achieve wide practicability and promotion Sexuality, cost saving and work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

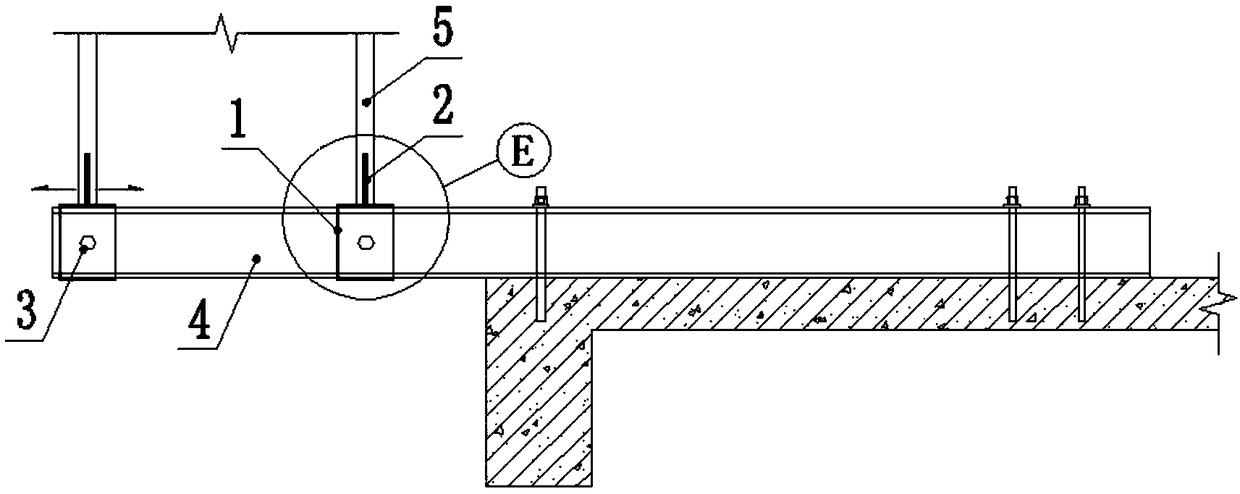

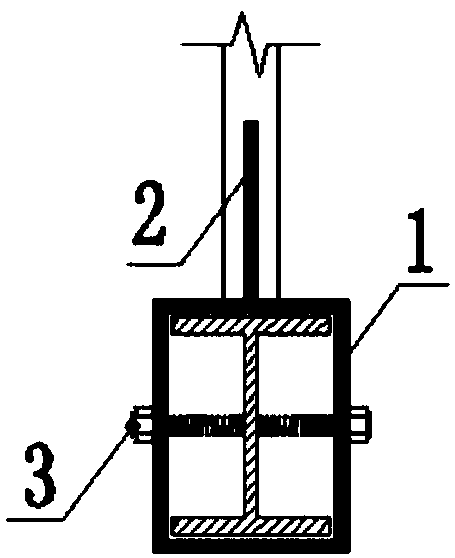

[0012] Embodiment of the present invention: the structural diagram of the movable and adjustable vertical rod support on the cantilevered I-beam is as follows Figure 1~3 As shown, it includes a cantilevered I-beam 4, a square steel sleeve 1 is set on the cantilevered I-beam 4, a connecting rod 2 is welded on the top of the square steel sleeve 1, and a vertical rod 5 is connected on the connecting rod 2. At the same time, both sides of the square steel sleeve 1 are provided with threaded holes, and the bolts 3 are screwed into the threaded holes to contact and tighten with the cantilevered I-beam 4 . Described connecting rod 2 is threaded steel bar, and vertical rod 5 is the steel pipe that the lower end is provided with internal thread, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com