Air flow and multi-stage drum type electrostatic combined foreign fiber separation device

A technology of airflow separation and separation device, which is applied in fiber processing, textiles and papermaking, mechanical processing, etc. It can solve the problems of low removal rate of foreign fibers, short charging time, economic loss of cotton processing enterprises, etc., and achieve high rejection rate, The effect of efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

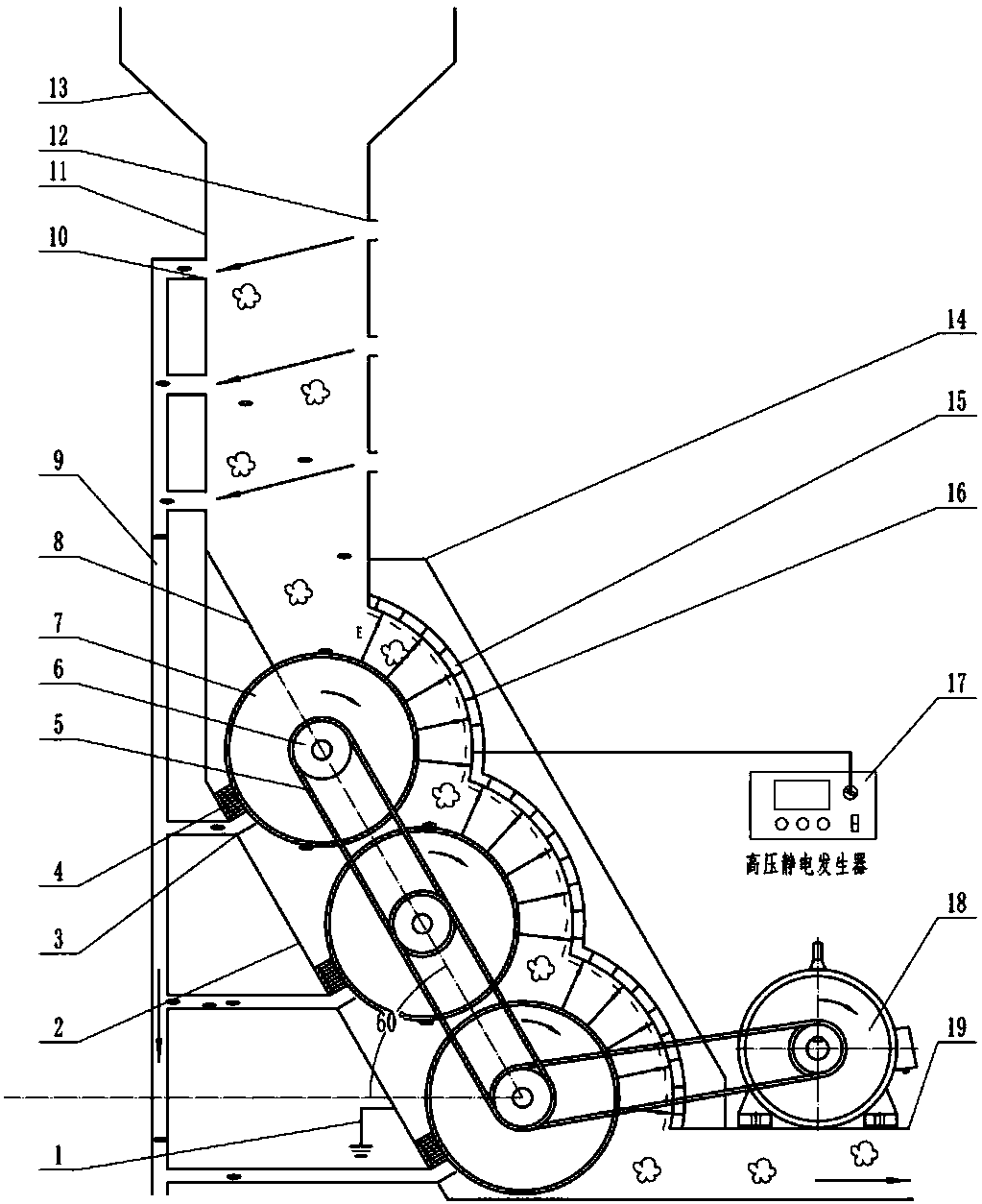

[0013] Embodiment 1: with reference to attached figure 1 , this embodiment: including feeding port (13), airflow separation device housing (11), airflow separation foreign fiber inlet (10), airflow opening (12), foreign matter negative pressure conveying pipeline (9), conveying slide plate (8 ), electrostatic separation device housing (2), motor (18), roller (7), pulley (6), belt (5), electrode plate (15), electrostatic electrode (16), electrostatic separation foreign fiber inlet ( 3), hair brush (4), protective cover (14), high-voltage electrostatic generator (17), grounding terminal (1) and seed cotton outlet (19); 13) It is arranged on the top of the whole device, the airflow separation device housing (11) is arranged below the feeding port (13), and the corresponding airflow separation device housing (11) is provided on the right side The airflow opening (12) is provided with the airflow separation foreign fiber inlet (10) on the left side of the airflow separation device...

Embodiment 2

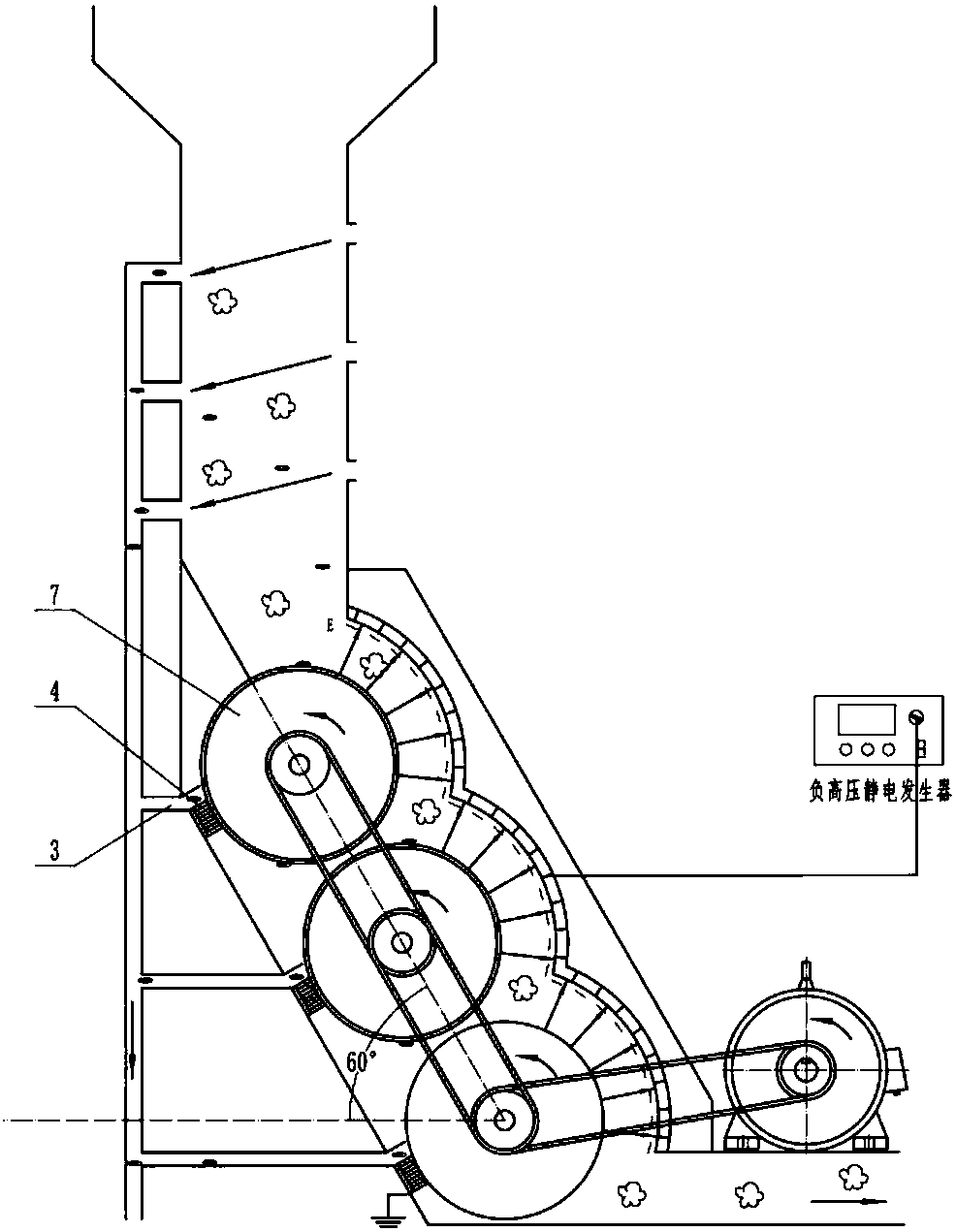

[0015] Embodiment 2: with reference to attached figure 2 , when the airflow and multi-stage drum type electrostatic combined foreign fiber separation device is working, the motor drives the drum to rotate counterclockwise, which can also achieve the purpose of cleaning foreign fibers; on the basis of Example 1, the following changes are made, the electrostatic separation of different The fiber inlet (3) is arranged on the upper side of the hair brush (4), and the motor (18) drives the cylinder (7) to rotate counterclockwise, and foreign fibers are brushed off by the hair brush (4) and fall into the electrostatic separation foreign fiber inlet (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com