Ecological engineering purification system suitable for micro-polluted source water

A technology of ecological engineering and purification system, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of reducing chemical consumption and reducing turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

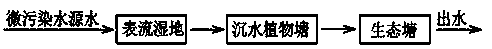

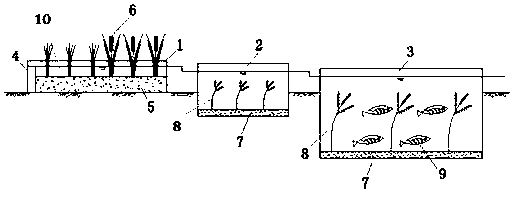

[0021] figure 1 It is a process flow diagram of an ecological engineering purification system applicable to slightly polluted source water of the present invention, figure 2 It is a structural schematic diagram of an ecological engineering purification system suitable for slightly polluted source water of the present invention. Such as figure 1 and figure 2 As shown, the ecological engineering purification system suitable for slightly polluted source water is provided with a surface flow wetland 1, a submerged plant pond 2 and an ecological pond 3. The surface flow wetland 1, the submerged plant pond 2 and the ecological pond 3 are connected by pipelines, and the water levels of the three units are lowered in turn.

[0022] First, the slightly polluted source water is lifted by the pump or flows by itself to the water distribution area 4 at the front end of the surface flow wetland 1, and the raw water entering the water distribution area 4 flows into the wet area 10. The...

Embodiment 2

[0026] The source water of a certain river course is slightly polluted. The various water quality indicators are: turbidity 35 ~ 70 NTU, oxygen consumption 6 ~ 7 mg / L, ammonia nitrogen 0.5 ~ 1.0 mg / L, and a kind of water source suitable for slightly polluted water source is used in Example 1. The water is treated by the ecological engineering purification system:

[0027] Slightly polluted source water is pumped to the surface flow wetland 1, the surface flow wetland 1 is 5.15m long x 0.8m wide x 0.8m high, of which the water distribution area 4 is 0.15 m long, and the water distribution area 4 realizes uniform water distribution; the surface flow wetland 1 The substrate is yellow sand with a particle size of less than 2 mm. The first half of the area is planted with Zizania angustifolia, and the rear half area is planted with Cattail angustifolia, with a planting density of 20 plants / m. 2 The water depth of the surface flow wetland 1 is 0.3m, and the hydraulic retention time ...

Embodiment 3

[0030] The source water of a certain river course is slightly polluted. The various water quality indicators are: turbidity 40 ~ 80 NTU, oxygen consumption 5 ~ 6 mg / L, ammonia nitrogen 0.6 ~ 0.9 mg / L, using a kind of method in Example 1 suitable for slightly polluted water sources The water is treated by the ecological engineering purification system:

[0031] Slightly polluted source water is pumped to the surface flow wetland 1, the surface flow wetland 1 is 5.15m long x 0.8m wide x 0.8m high, of which the water distribution area 4 is 0.15 m long, and the water distribution area 4 realizes uniform water distribution; the surface flow wetland 1 The substrate is yellow sand with a particle size of less than 2 mm, and watercress and cold-resistant iris are planted at a planting density of 25 plants / m 2 The water depth of surface flow wetland 1 is 0.4m, and the hydraulic retention time is 1 day; the raw water enters the submerged plant pond 2 after passing through the surface fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com