Efficient recovery process and device for waste mercury catalyst

A waste mercury catalyst and high-efficiency technology, applied in chemical recovery, mercury halide, inorganic chemistry, etc., can solve problems such as safety hazards, system instability, corrosion resistance and high temperature resistance, etc., and achieve high recovery rate, cost reduction, and efficient recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

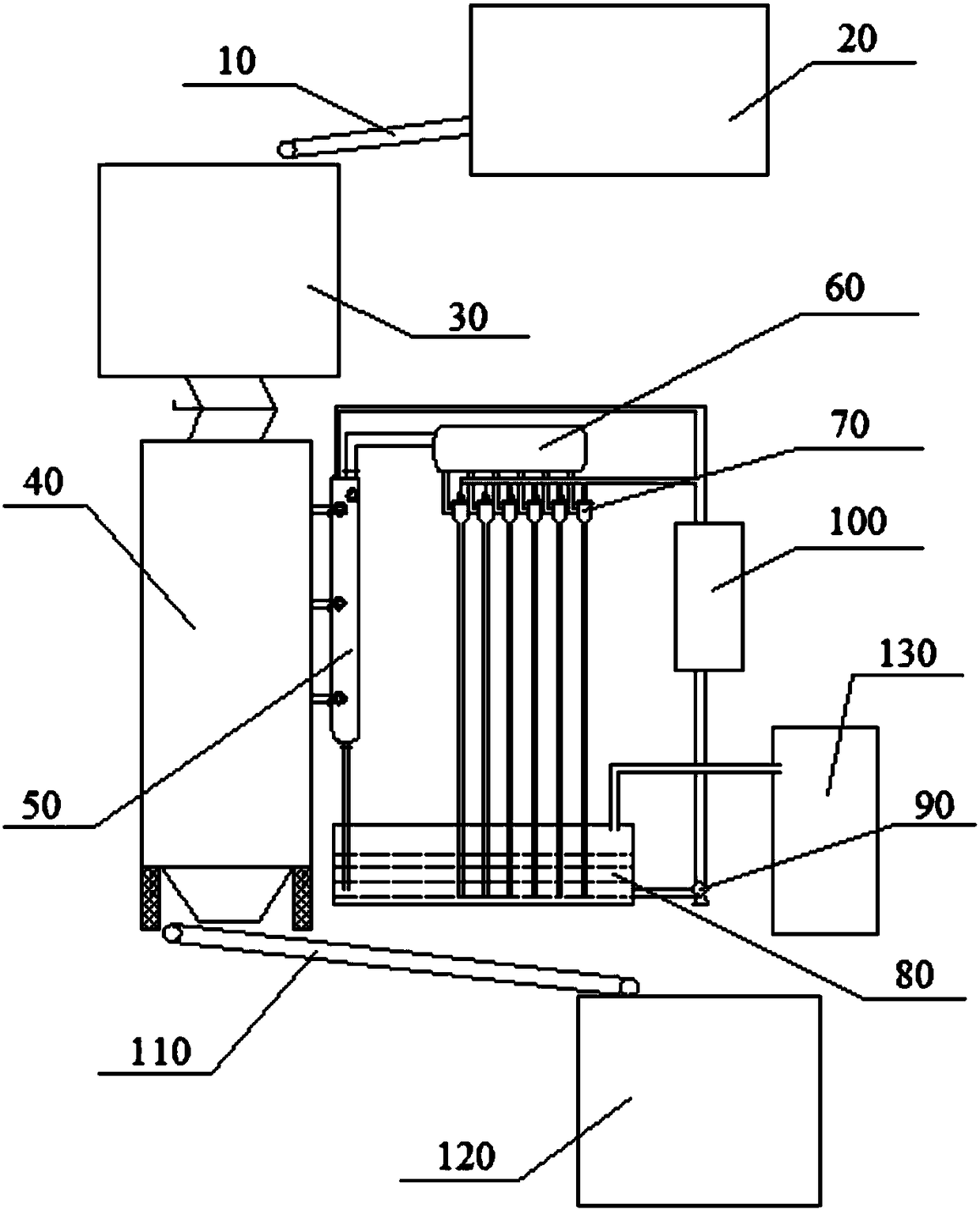

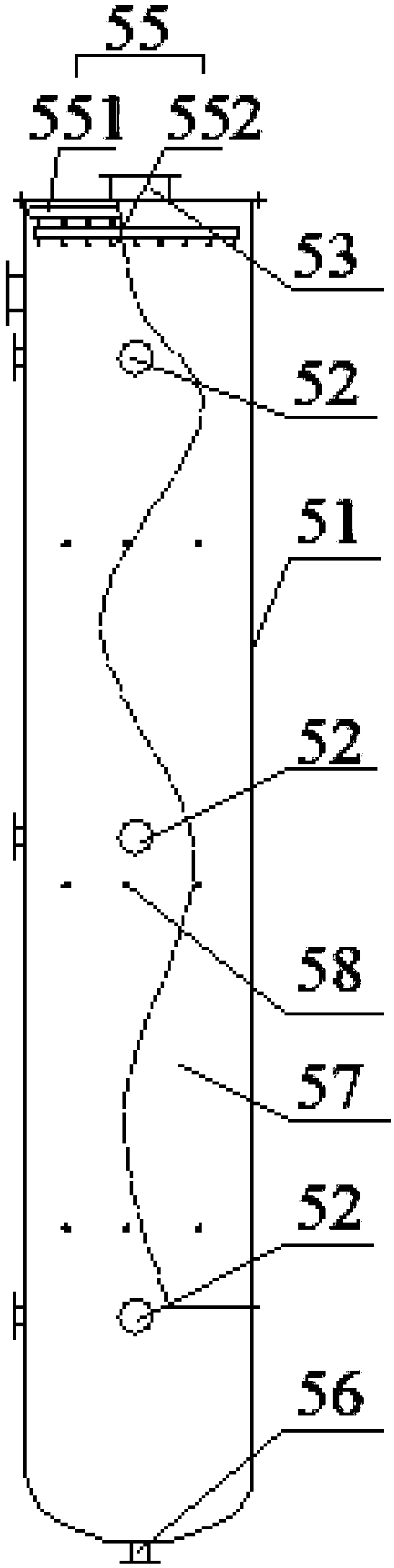

[0028] In combination with the accompanying drawings of the present invention, the technical solutions of the embodiments of the invention will be further elaborated in detail.

[0029] A process for efficiently recovering spent mercury catalysts, comprising the following steps:

[0030] S1: High-voltage electrostatic treatment: After the waste mercury catalyst is treated with a high-voltage pulse electric field, the waste mercury catalyst to be heated is obtained; the electric field strength of the high-voltage pulse electric field is not less than 30kV / cm, the pulse width is 0-100μs, and the pulse frequency is 1000- 2000Hz.

[0031] S2: waste mercury catalyst heating: the waste mercury catalyst to be heated with a mercury content higher than 1% is in the recovery furnace 40, and the temperature in the recovery furnace 40 reaches at least 320°C, which is 320~500°C, so that the waste mercury catalyst in the waste mercury catalyst The mercuric chloride leaves the activated carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com