Link-chain-type egg conveying equipment

A transmission equipment and chain-type technology, which is applied in the direction of lighting and heating equipment, conveyors, conveyor objects, etc., can solve the problems of increased egg breaking rate, increased cost, increased customer production cost and shipment risk, etc., to achieve reduction Manufacturing cost and the effect of reducing the broken egg rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

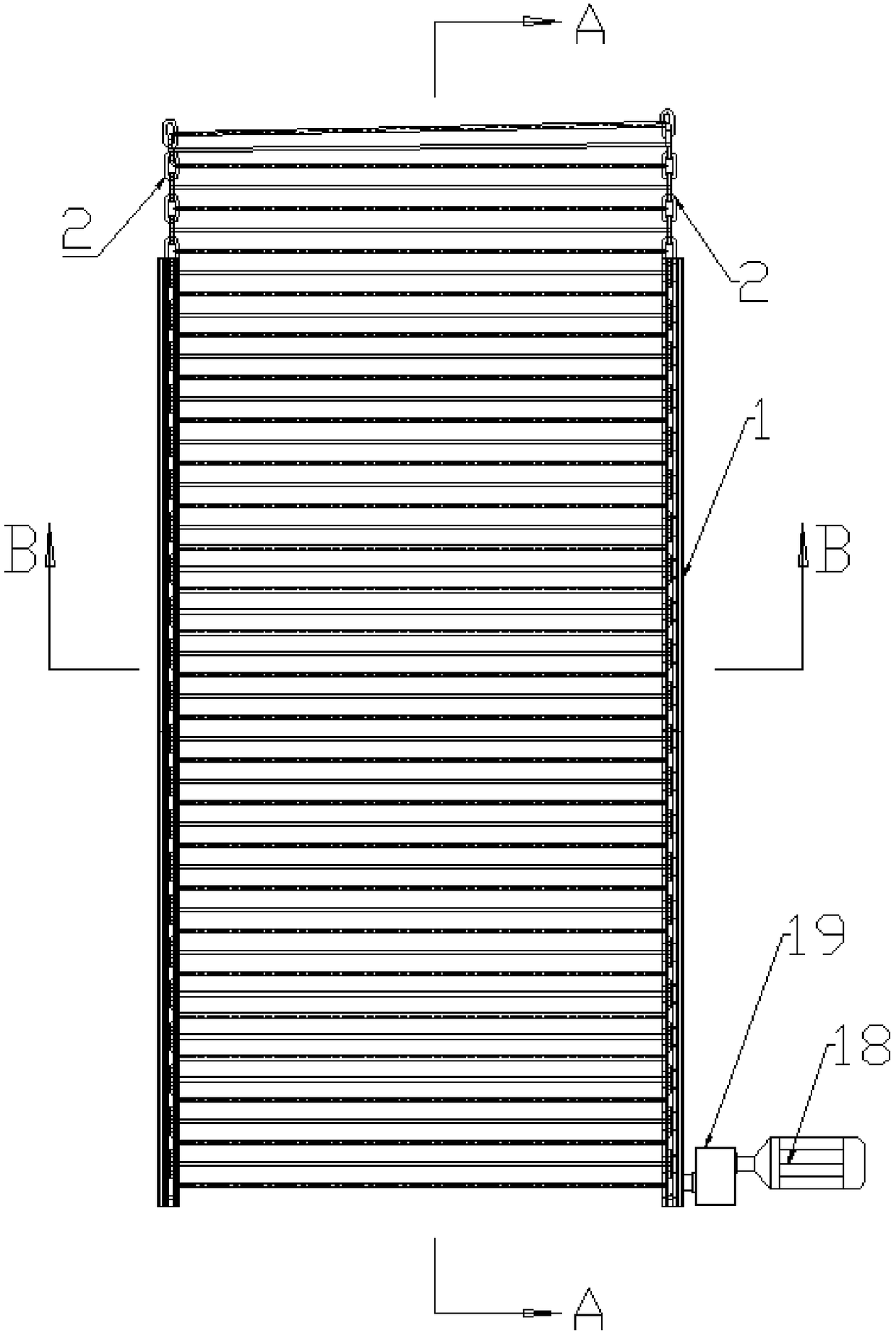

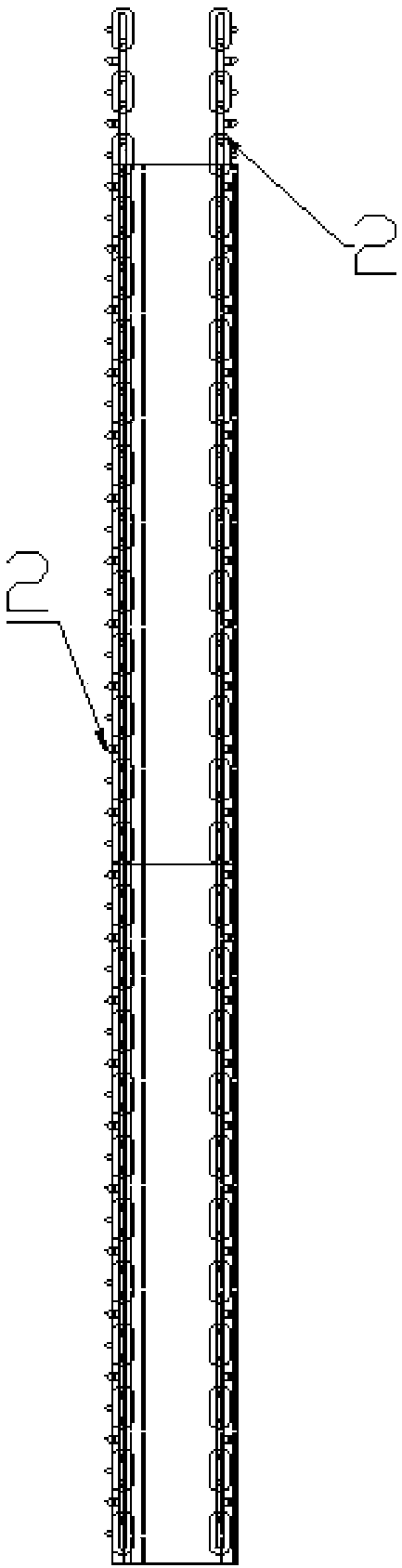

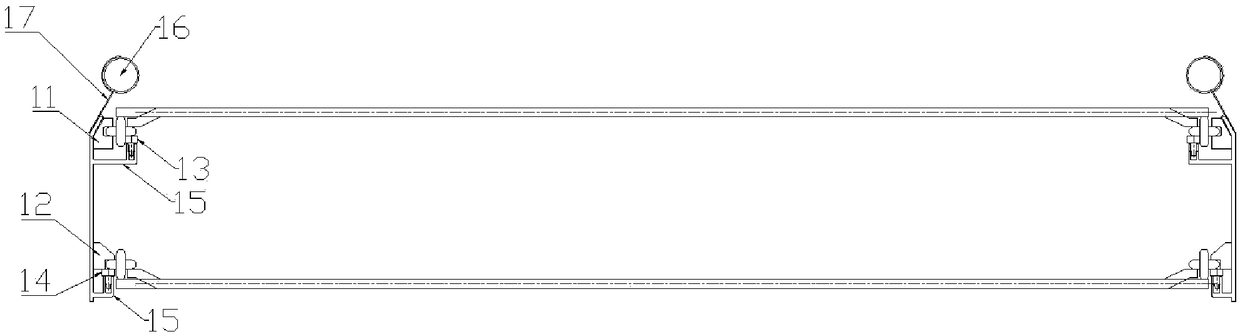

[0030] like Figure 1-Figure 9 As shown, the present invention provides a chain-type egg conveying equipment, including a frame 1, the frame 1 is composed of aluminum side plates on both sides and a beam connected between the aluminum side plates, the frame 1 There is an egg conveying channel inside, and the two sides of the egg conveying channel are aluminum side plates. The frame 1 is equipped with a chain drive wheel group and at least one chain guide wheel group located inside the egg conveying channel. The chain drive A chain conveyor belt group surrounds the wheel group and the chain guide pulley group. The chain conveyor belt group can be driven by the mutual cooperation between the chain drive wheel group and the chain guide pulley group. It runs in the egg channel to transport eggs to different stations, and the chain drive wheel set is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com