High-temperature-resistant camouflage fabric production process

A production process and high temperature resistance technology, applied in the field of fabrics, can solve the problems of reducing the service life of equipment, equipment damage, improving textile efficiency, etc., to achieve the effect of improving service life, preventing equipment damage, and facilitating timely maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

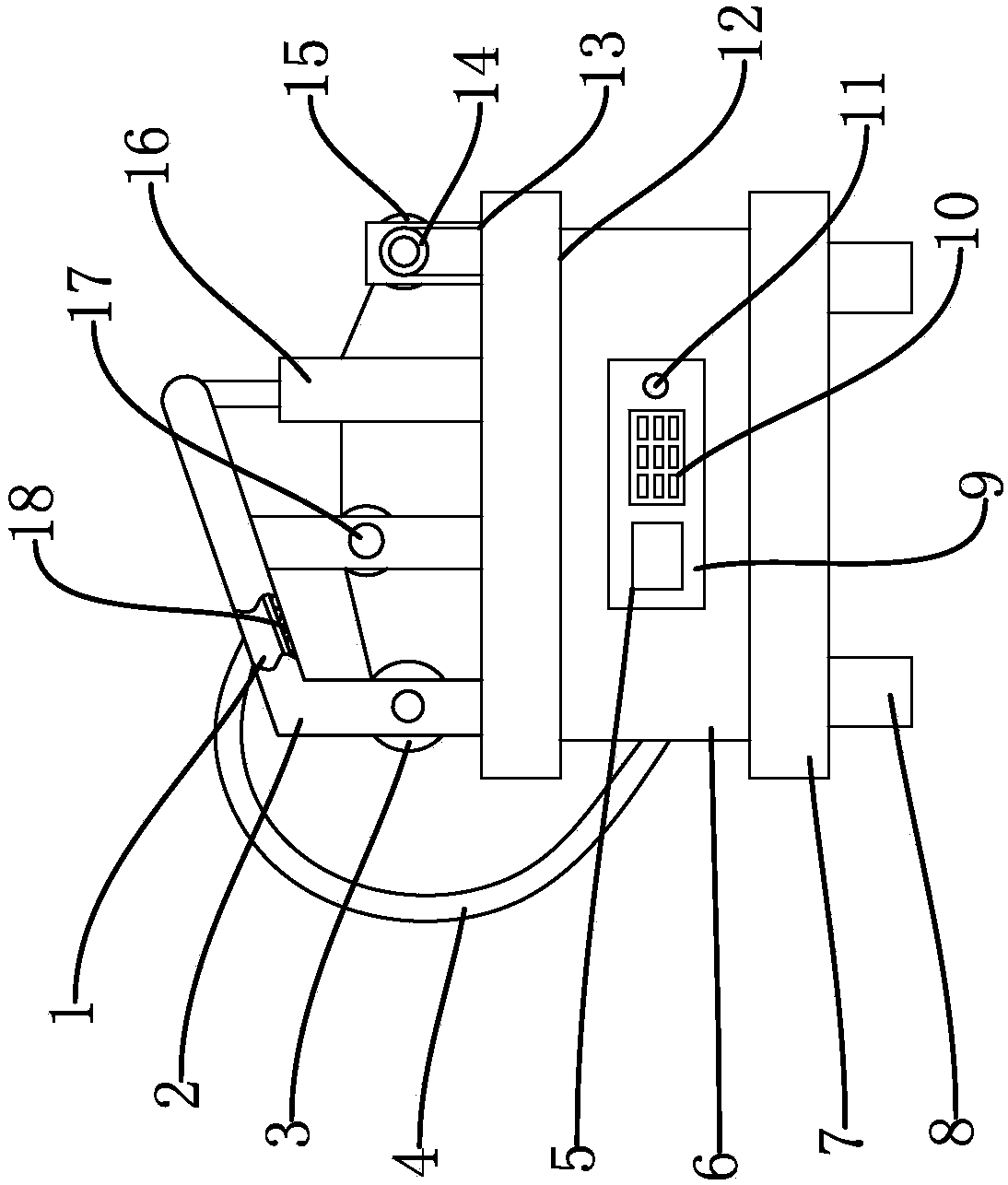

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

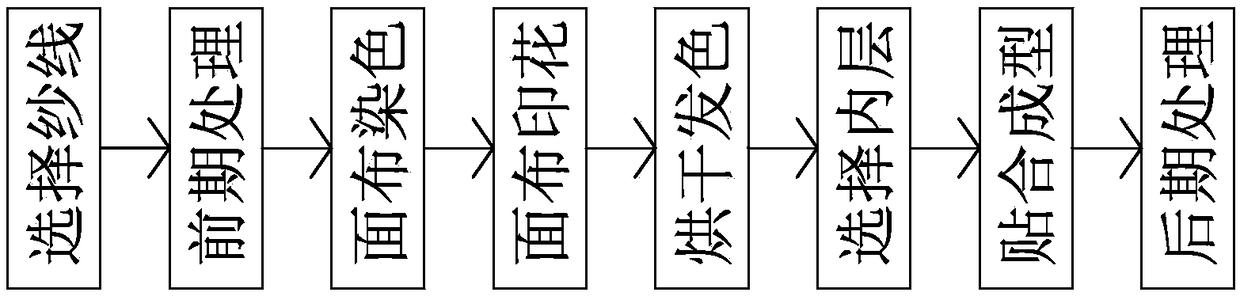

[0031] Such as Figure 1-4 Shown, a kind of manufacture craft of high temperature resistant camouflage fabric, this manufacture craft comprises the following steps:

[0032] S1, select yarn: weave warp and weft into face cloth by a kind of textile machine, described warp adopts spandex fiber, described weft adopts blended polyester;

[0033] S2. Early treatment: Singeing is performed on the front and back of the face cloth by a singeing machine at a temperature of 1000-1180°C;

[0034] S3, face cloth dyeing: put the face cloth after S2 singeing into the dye vat for dyeing, the dyeing time is 30-40 minutes, and the dyeing temperature is 90-100°C;

[0035] S4, face cloth printing: the face cloth after S3 dyeing is carried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com