Preparation method and application of rey molecular sieve adsorbent for ultra-deep removal of thiophene sulfides in gasoline

A technology of molecular sieves and adsorbents, which is applied in the field of preparation of REY molecular sieve adsorbents, can solve the problems of small number of active sites for adsorption of rare earth species, great difference in industrial demand, and low utilization rate of rare earths, so as to reduce the preparation cost and improve the utilization rate , the effect of reducing the roasting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

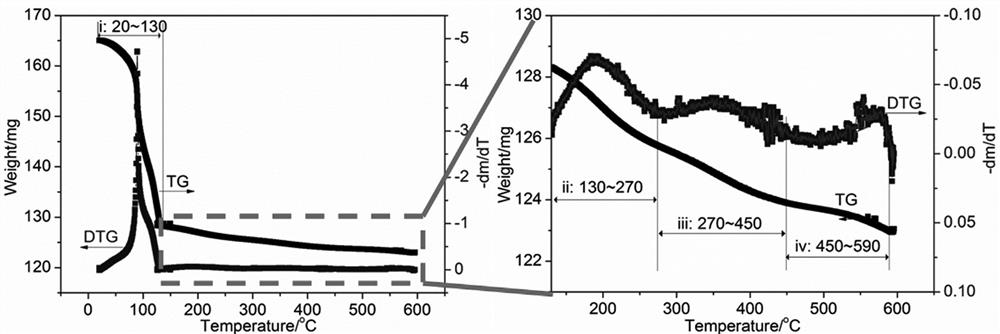

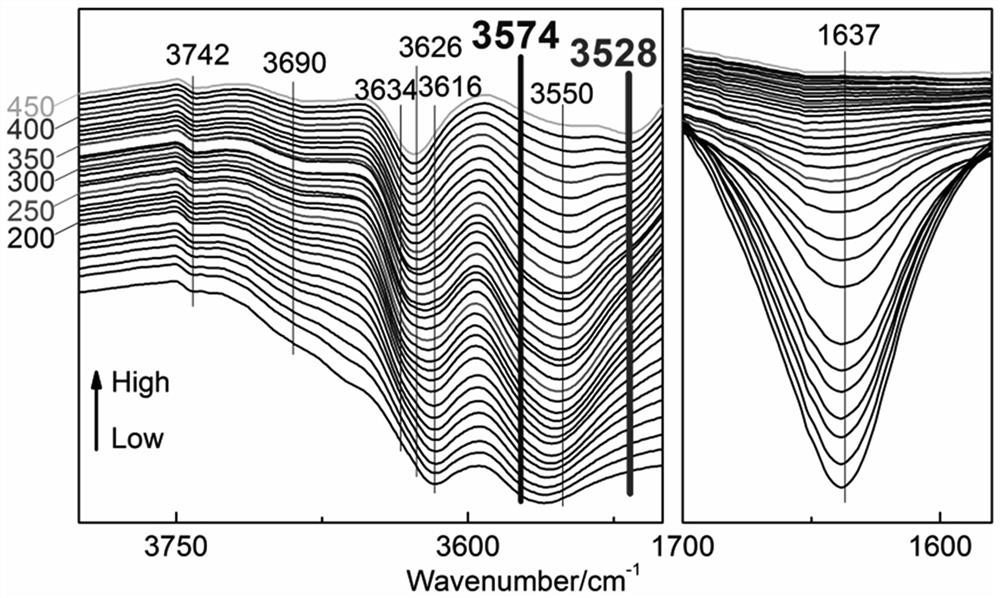

Method used

Image

Examples

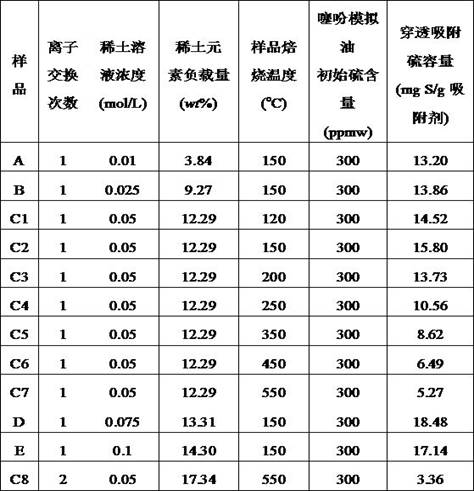

Embodiment 1

[0039] Weigh 5.0 g of NaY molecular sieve raw powder (molar ratio of silicon to aluminum is 2.65), measure 125 ml of cerium nitrate solution with a concentration of 0.01 mol / L, put the two into a three-necked flask connected to a condenser tube, and place the Stirring in a magnetic stirrer, the temperature of the oil bath was controlled at 100 o C, after stirring for 6 h (rotation speed: 400~500 r / min), cool to 80 o C, using 80 o Suction filtration with distilled water of C, washed to neutrality, and the obtained filter cake was dried in a drying oven for a day and night, and then the dried sample was placed in 150 oC , Activated under nitrogen atmosphere for 6 h to obtain sample A, the loading amount of Ce element was measured to be 3.84 by XRF analysis wt %.

[0040] Dissolve 0.2772 g of thiophene in 500 mL of n-octane to prepare a thiophene simulated oil with a sulfur content of 300 ppm. Weigh 1.0 g of adsorbent A, grind it into 100-mesh particles, and place them in a ...

Embodiment 2

[0042] All the other are the same as Example 1, the difference is: the concentration of cerium nitrate solution is 0.025 mol / L, exchange, filter, dry, and roast to obtain sample B, through XRF analysis, it is recorded that the loading capacity of Ce element is 9.27 wt %.

[0043] The rest are the same as in Example 1, except that: when the sulfur content in the liquid phase product is greater than zero, the breakthrough adsorption sulfur capacity of the adsorbent B is 13.86 mg S / g adsorbent B.

Embodiment 3

[0045] All the other are with embodiment 1, difference is: the concentration of cerium nitrate solution is 0.05 mol / L, and roasting temperature is 120 oC , to obtain sample C1, which was analyzed by XRF, and the loading amount of Ce element was measured to be 12.29 wt %.

[0046] The rest are the same as in Example 1, except that the breakthrough adsorption sulfur capacity of the adsorbent C1 is 14.52 mg S / g adsorbent C1 when the sulfur content in the liquid phase product is measured to be greater than zero.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com