Motor with heat radiation function

A function and casing technology, applied in the field of motors with heat dissipation function, can solve problems such as burning out the motor, and achieve an obvious effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

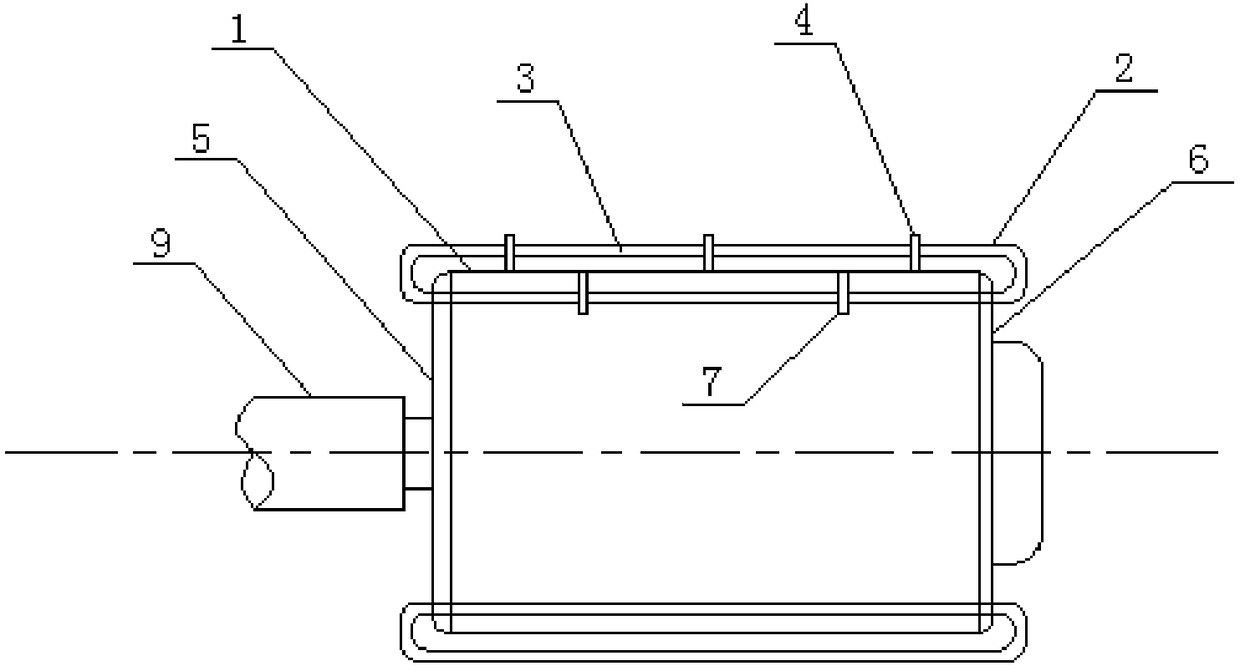

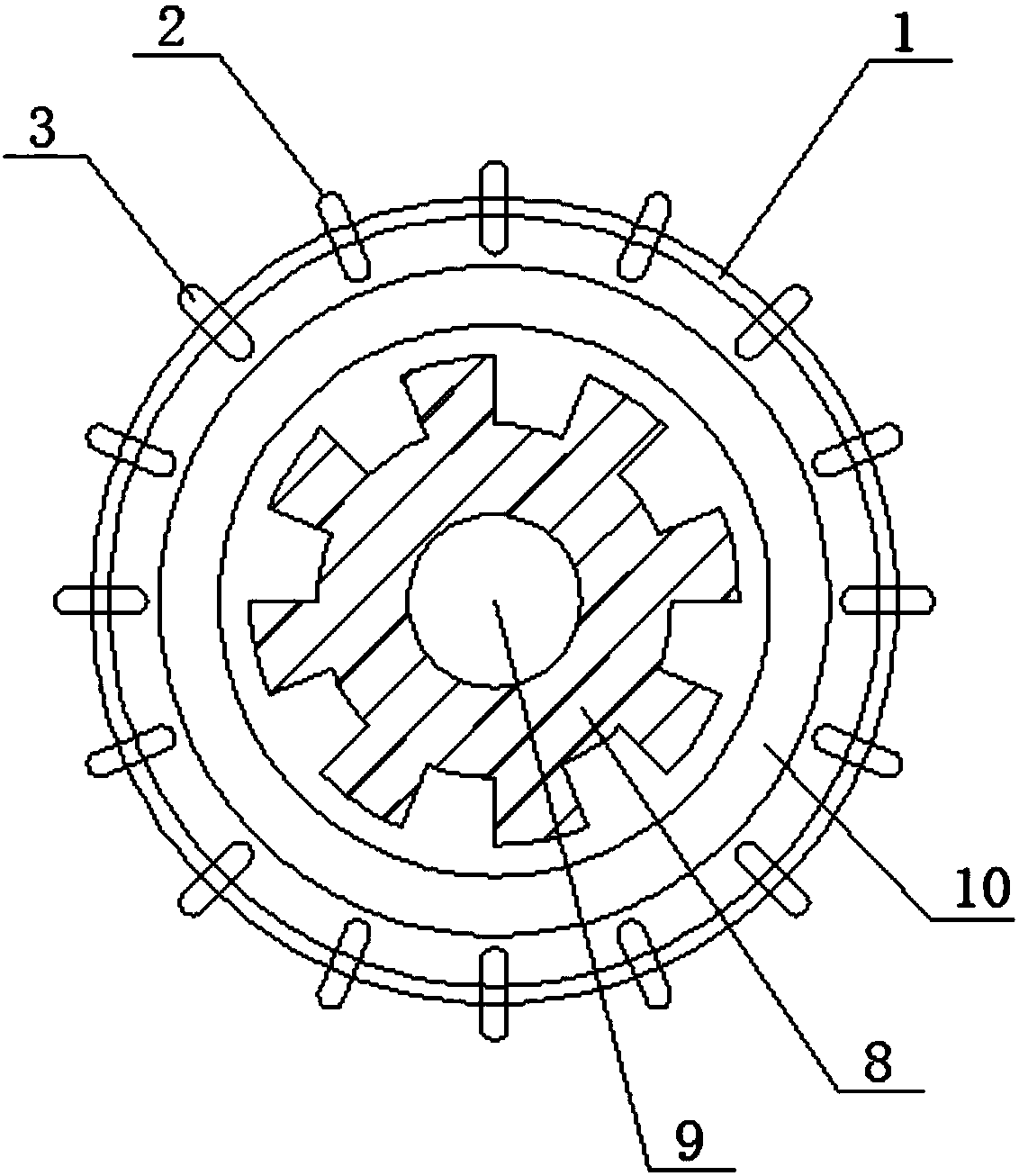

[0023] Such as figure 1 As shown, the present invention provides a motor with heat dissipation function, including a motor casing 1, a stator 10, a rotor 8 and an output shaft 9, and the motor also includes a return tube 2 and a phase change material 3. The motor case 1 is cylindrical, and the two ports are openings. The return-shaped tube 2 passes through the two ports in the axial direction and is looped on the shell wall of the motor case 1. The return-shaped tube 2 It consists of four parts, namely the inner pipe section, the outer pipe section and two semi-circular bends. The inner pipe sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com