Single-piston linear power generation engine

A linear power generation, single-piston technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of reduced mechanical and energy conversion and transfer efficiency, low energy transfer efficiency of the whole system, and unstable generator operation. Achieve high energy conversion efficiency, improve system reliability, and reduce mechanical losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

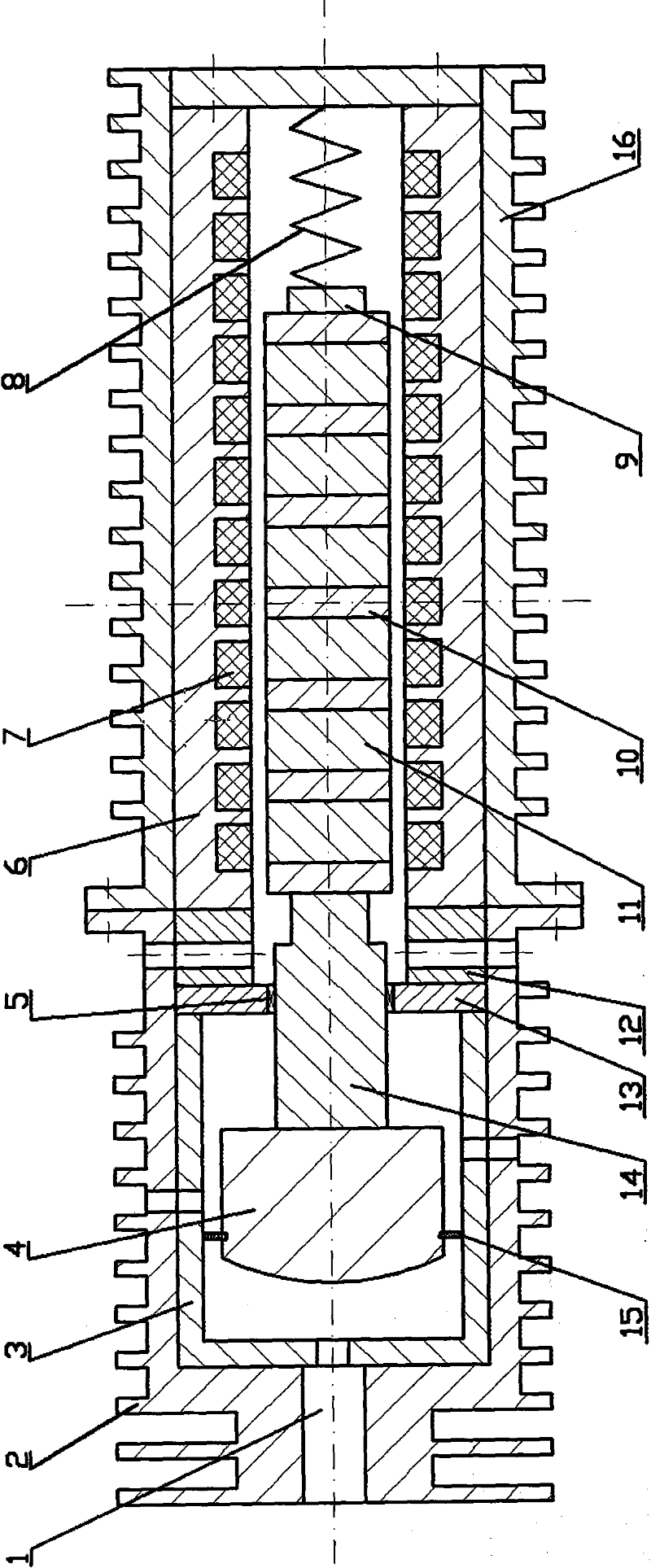

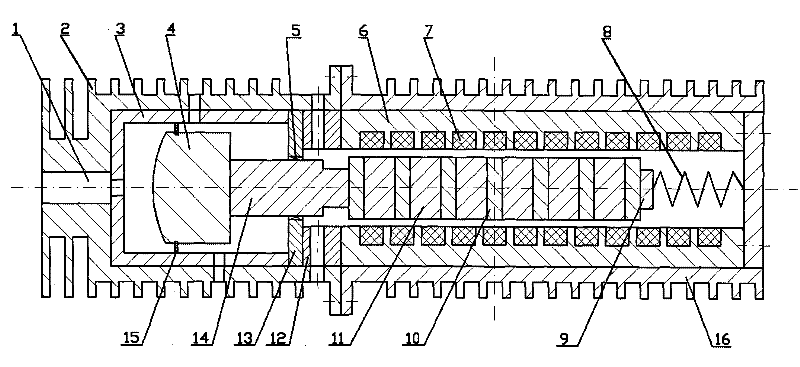

[0015] A kind of single-piston linear generator engine of the present invention, as figure 1 As shown, it includes cylinder A2, cylinder B16, compression spring 8, contact block 9, secondary permanent magnet 11, bracket 10, main shaft 14, piston 4, end cover 13, piston ring 15, primary iron core 6, winding 7 , heat insulating gasket 12, sliding bearing 5, cylinder liner 3 and spark plug 1; its connection relationship is: the cylinder block B16 is a sleeve, and its outer wall is zigzag for heat dissipation; The primary iron core 6, the primary iron core 6 is a cylinder with a cavity, the inner wall of the primary iron core 6 is evenly dug with grooves, the winding 7 is embedded in the groove of the primary iron core 6 and fixedly connected with the primary iron core 6 ; A compression spring 8 is fixed in the cavity of the primary iron core 6 and at the center of the bottom of the cylinder B16, and the compression spring 8 is fixedly connected to the contact block 9; the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com