Flexible cable self-adaptive guide wheel and guide method thereof

A guide wheel, self-adaptive technology, applied in belt/chain/gear, portable hoisting device, hoisting device, etc., can solve the problem that the balance rope and the anti-jump rod are stuck, the maintenance of the balance rope is time-consuming and laborious, and affects the normal operation of the hoisting system. Operation and other problems, to achieve the effect of light weight, low cost, good cushioning and shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

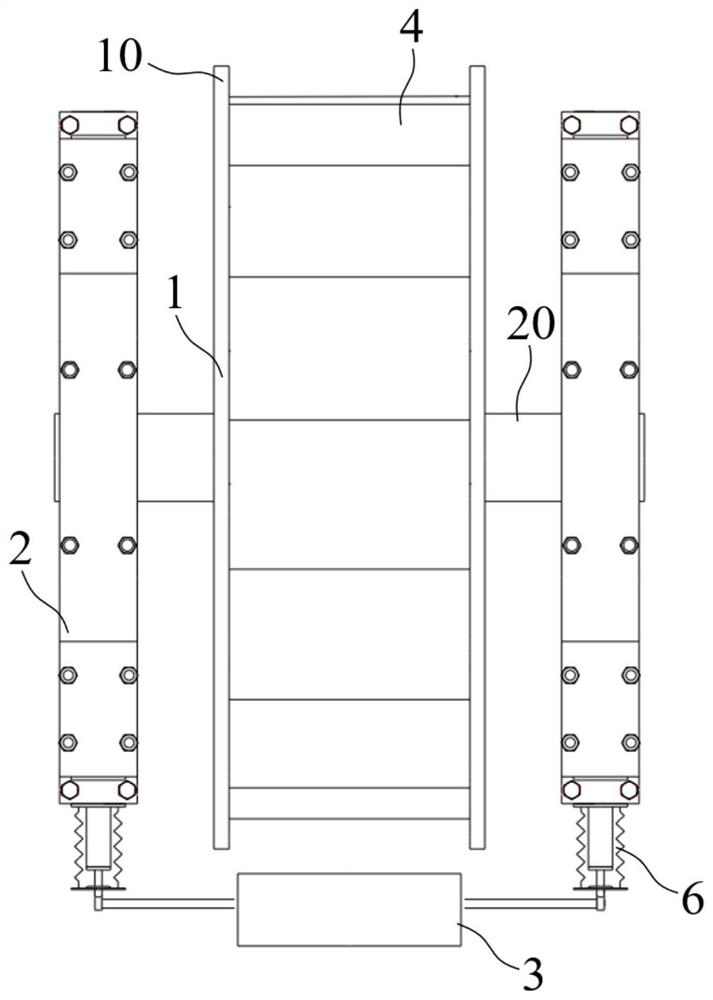

[0058] The flexible cable adaptive guide wheel of this embodiment includes,

[0059] The guide wheel main body 1 has guide wheel side plates 10 formed on both sides thereof;

[0060] Guide wheel support 2, it is connected with guide wheel main body 1 by guide wheel axle 20;

[0061] The anti-job-hopping rod 3 is connected to the guide wheel bracket 2 at its end, and the anti-job-hopping rod 3 is horizontal to the guide wheel shaft 20 and placed in front of the guide wheel main body 1;

[0062] Also includes:

[0063] Liner 4, which surrounds the wheel surface of the guide wheel main body 1, the distance between the liner 4 and the axis of the guide wheel main body 1 is variable;

[0064] The distance from the outer edge of the guide wheel support 2 to the axis of the guide wheel main body 1 is greater than the maximum distance from the outer edge of the pad 4 to the axis of the guide wheel main body 1 .

[0065] In the existing guide wheel structure, the guide wheel main bo...

Embodiment 2

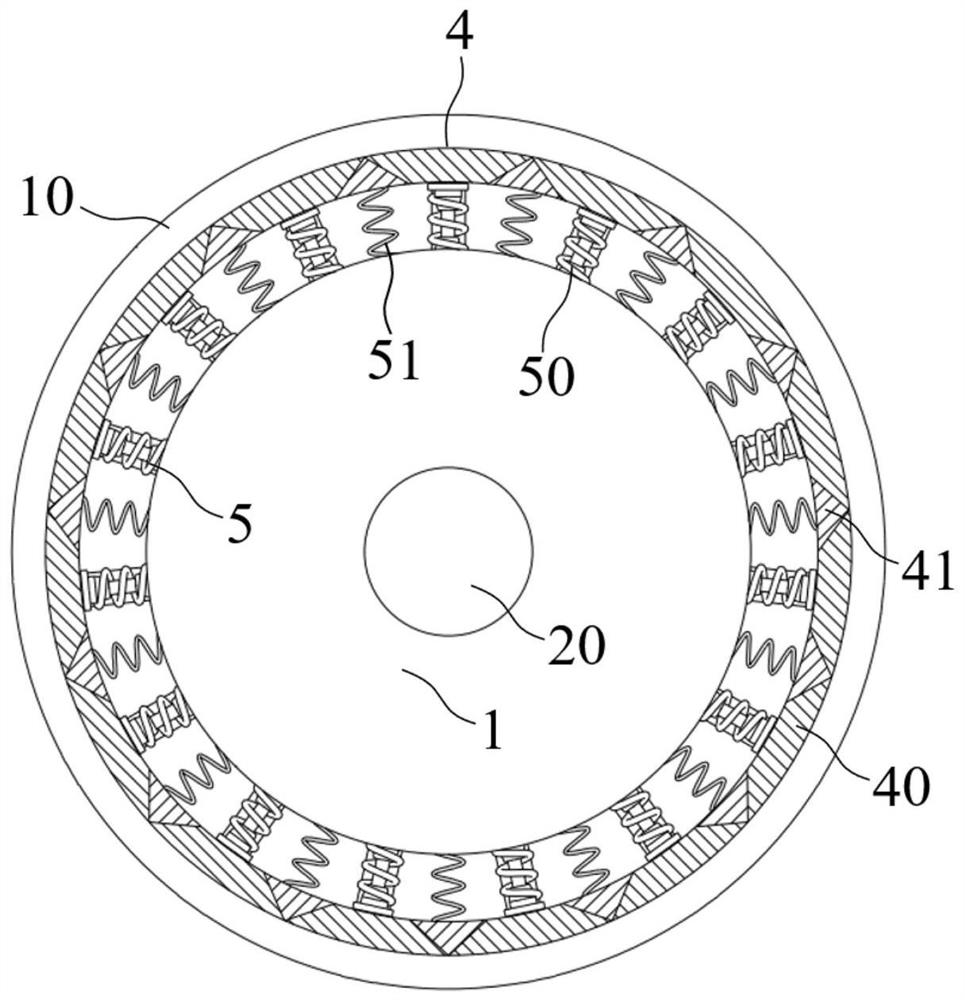

[0068] The cable adaptive guide wheel of this embodiment is further improved on the basis of embodiment 1, and further includes an elastic mechanism 5 through which the pad 4 is connected to the wheel surface of the guide wheel main body 1 .

[0069] The variable function of the distance between the liner 4 and the axis center of the guide wheel main body 1 is realized by the elastic mechanism 5. The elastic mechanism 5 described in this application includes but is not limited to structures such as rubber, springs, and dampers with deformation recovery properties. Realize that the liner 4 moves toward the axis of the guide wheel main body 1 after being stressed, and the member that restores the position of the liner 4 after releasing the force can be used as the elastic mechanism 5 to connect the liner 4 with the wheel surface of the guide wheel main body 1.

Embodiment 3

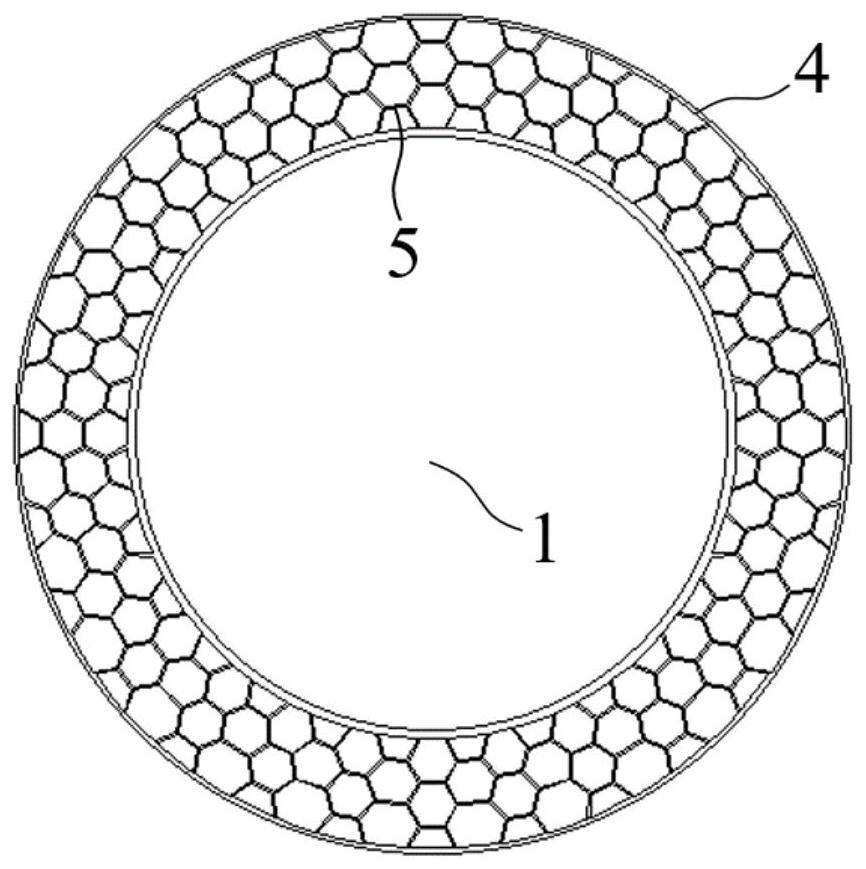

[0071] The flexible cable adaptive guide wheel of this embodiment is further improved on the basis of embodiment 2. The elastic mechanism 5 is an annular honeycomb rubber structure, which is formed around the wheel surface of the guide wheel main body 1, and the liner 4 The ring is connected to the outer edge of the annular honeycomb rubber structure.

[0072] This embodiment shows a structural form of the elastic mechanism 5, such as figure 2 As shown, the elastic mechanism 5 is annular rubber, which is sleeved on the wheel surface of the guide wheel main body 1. The interior of the annular rubber is honeycomb-shaped, and the gasket 4 is fixed on the outer edge surface of the annular rubber. When debris falls into the balance rope When it is in the guide wheel, during the movement of the balance rope, the debris acts on the liner 4 in contact with it, and the force on the liner 4 makes the ring-shaped rubber part connected to it deform, so that the liner 4 moves closer to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com