Apparatus for forming edge of lead of secondary battery

A secondary battery and lead technology, applied in the field of edge equipment, can solve the problem of difficulty in maintaining the consistency of cutting quality, and achieve the effect of improving the quality of film thermal bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Exemplary embodiments of the present disclosure will now be described in detail with reference to the accompanying drawings.

[0028] Hereinafter, an exemplary embodiment implementing an apparatus for forming an edge of a lead of a secondary battery according to the present disclosure will be described in detail with reference to the accompanying drawings.

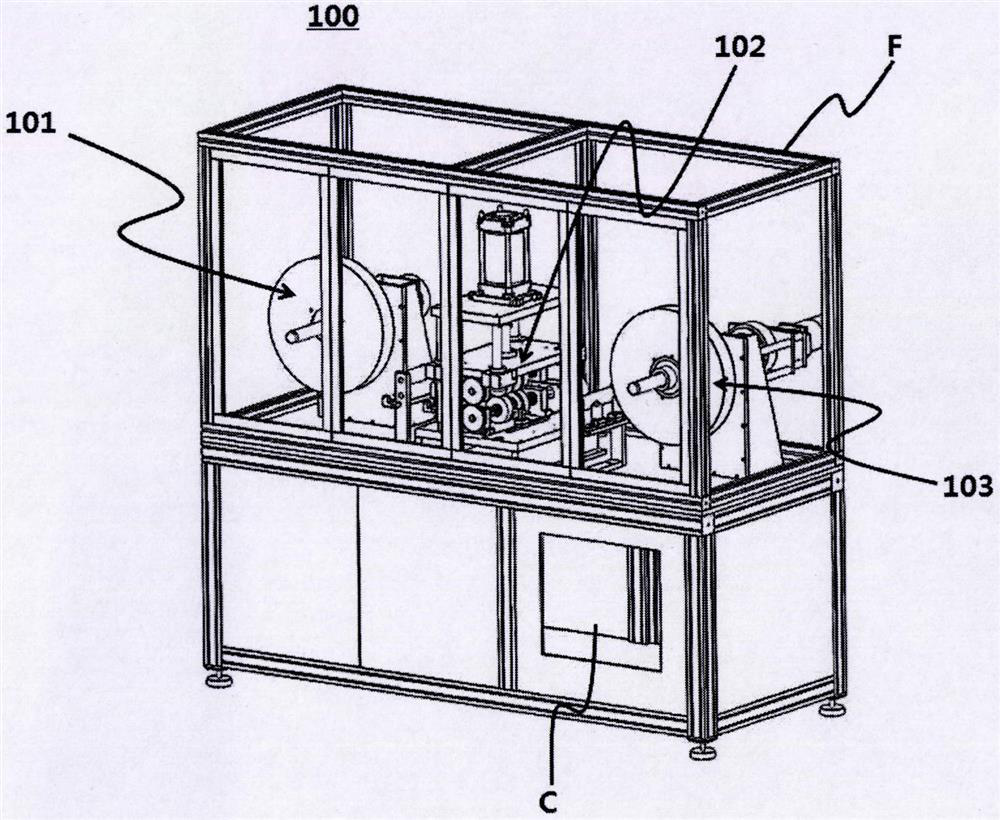

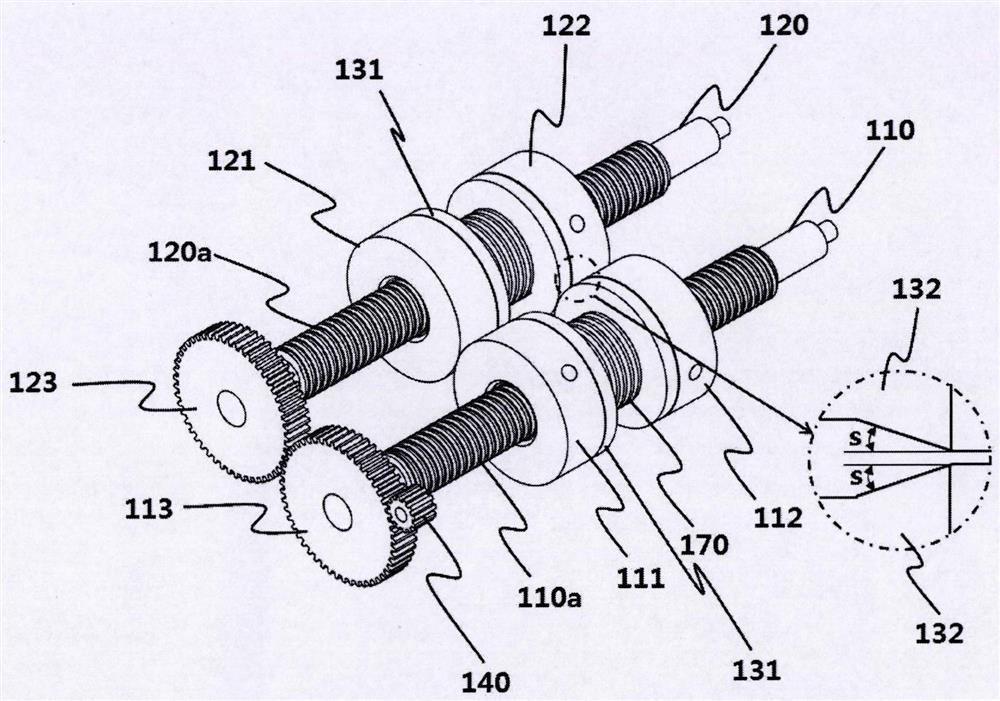

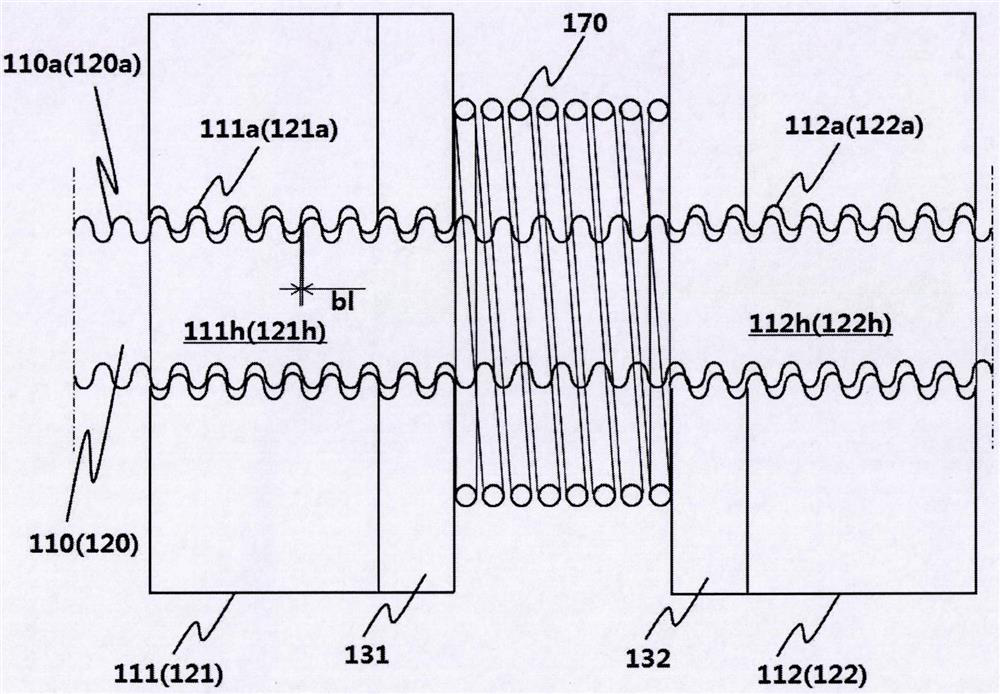

[0029] figure 1 is a view illustrating an appearance of an apparatus for forming an edge of a lead of a secondary battery according to an exemplary embodiment of the present disclosure, figure 2 with image 3 It is detailed instantiation processing figure 1 A view of the configuration of the lead edge in ; Figure 4 Is the instantiated execution processing figure 2 A view of the configuration required for the operation of the lead edge, Figure 5 It is a photograph illustrating the experimental results according to the shape of the pressing part.

[0030] refer to figure 1 , the apparatus 100 for forming an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com