Material receiving device suitable for silicon wafer production line

A material receiving device and production line technology, applied in transportation and packaging, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of bad product mixing, high labor intensity, high labor cost, reduce labor costs, and reduce secondary damage, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

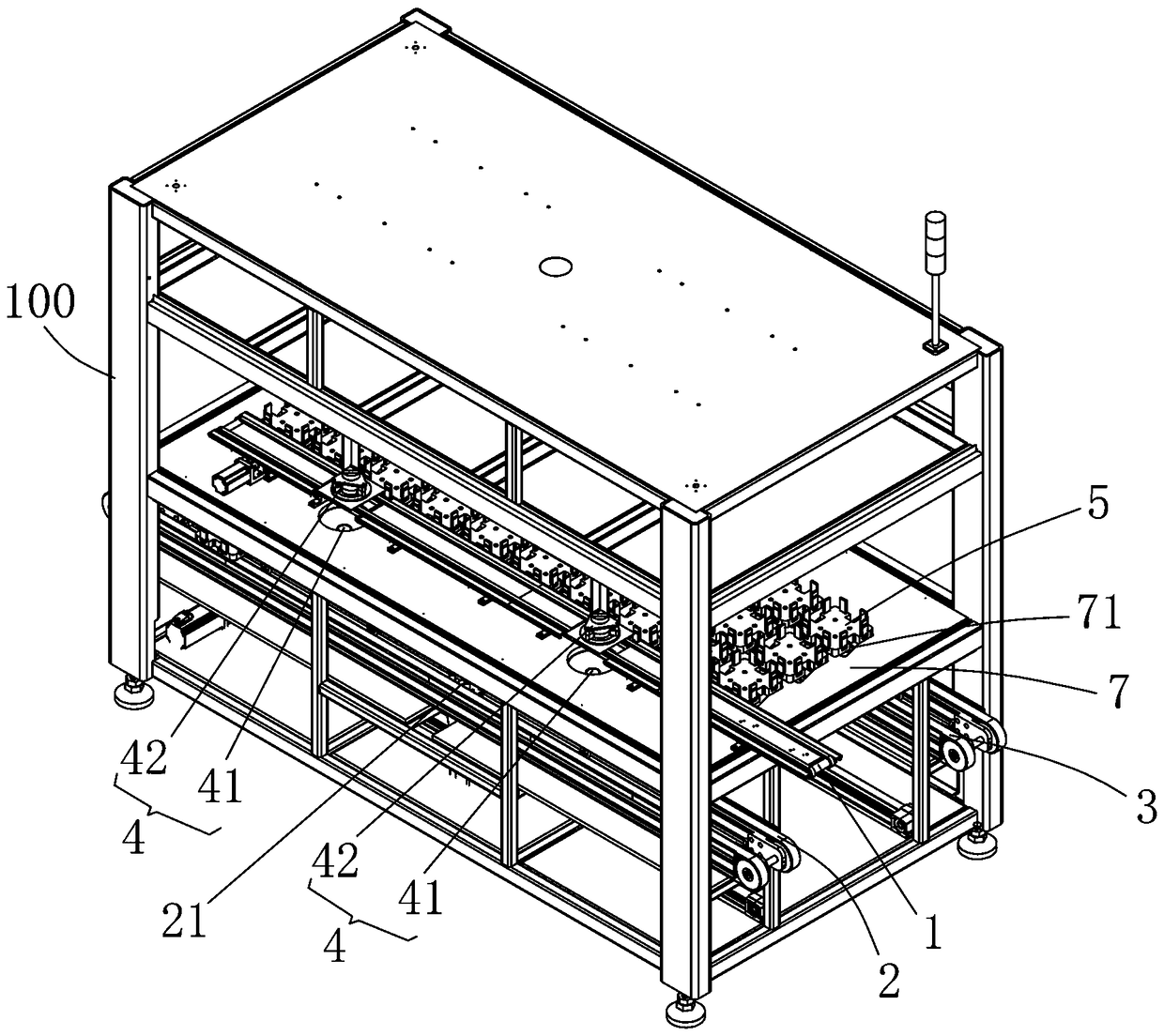

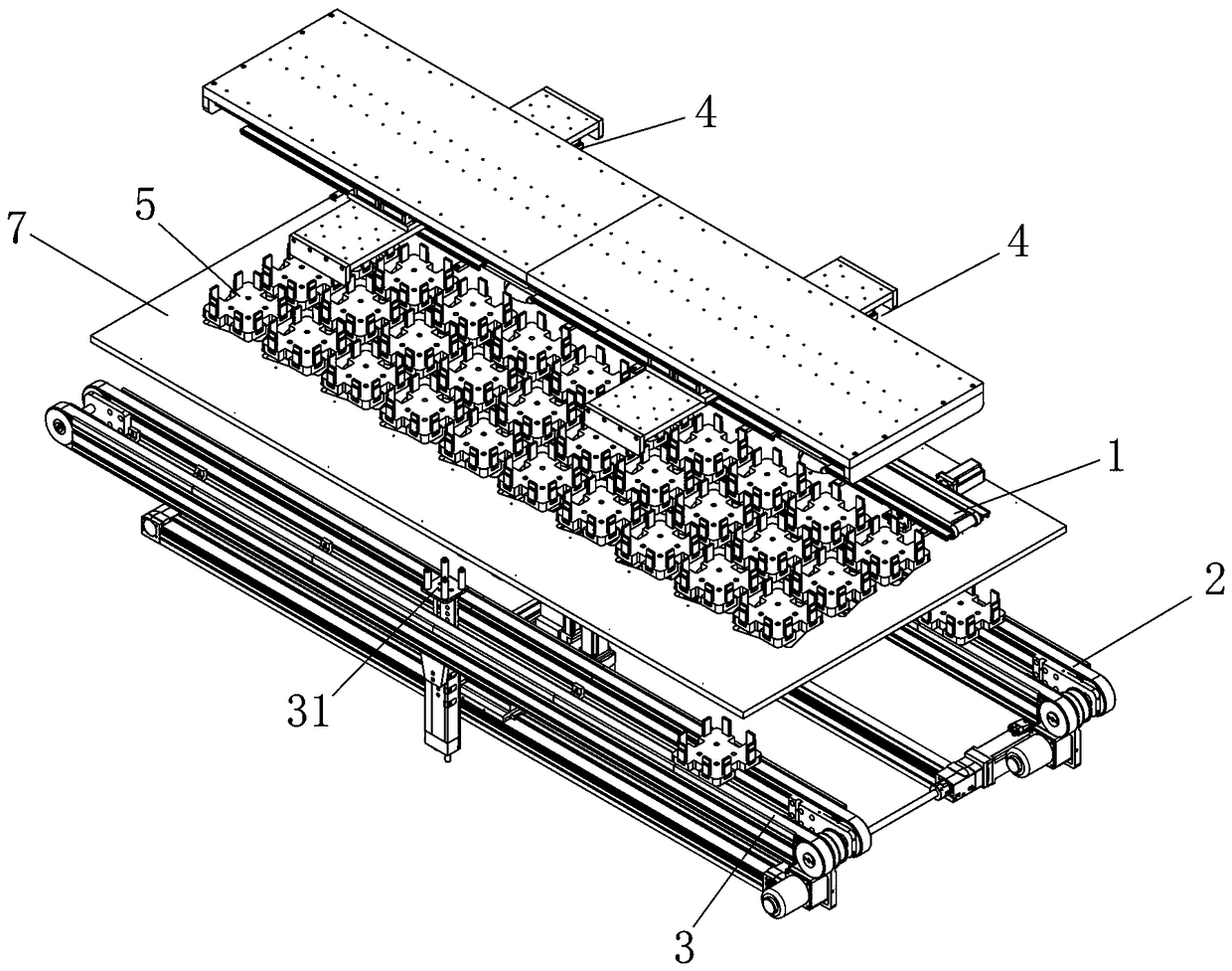

[0019] refer to figure 1 , 2 , 3, 4, 5, and 6 are schematic diagrams of preferred embodiments of the present invention. The present invention is related to a material receiving device suitable for a silicon wafer production line, which has a frame 100, a silicon wafer conveyor belt 1, an empty disk Conveyor belt 2, full-disc conveyor belt 3, visual detection and adjustment mechanism 4 and several receiving trays 5. The receiving tray 5 is placed in the set area and automatically placed and unloaded by the loading and unloading mechanism 6. The empty conveyor belt 2 provides the empty receiving tray 5 to the loading and unloading mechanism 6, and the full conveyor belt 3 receives the loading and unloading mechanism. 6 unloaded rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com