Smoked membrane structure

A film structure and diaphragm technology, applied in optics, instruments, optical components, etc., can solve the problems of lowering product grade specifications, increasing power consumption costs, and reducing equipment life, so as to achieve small barrier and absorption effects, avoid easy damage, and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

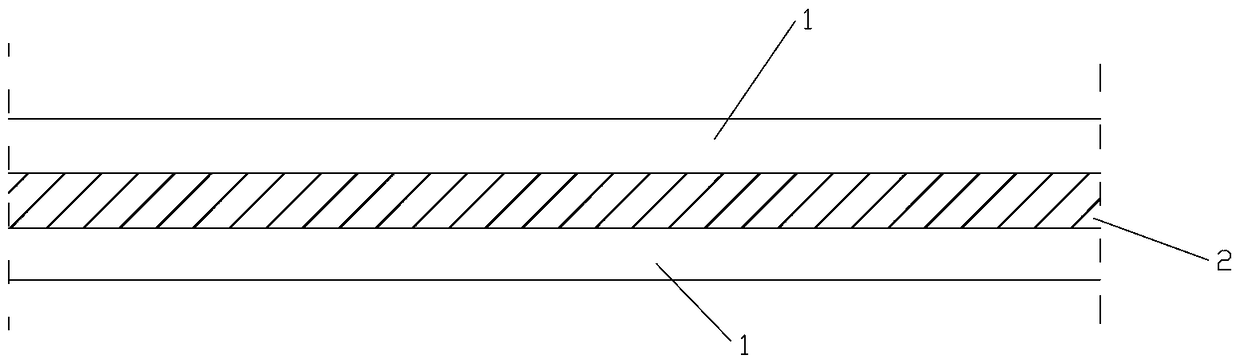

[0009] A smoked diaphragm structure comprises a transparent substrate 1 and a PVA layer 2 covering the inside of the transparent substrate, and the transparent substrate is a diaphragm made of a high light-transmitting material.

[0010] It should be noted that the scientific name of PVA is polyvinyl alcohol, which is in granular form.

[0011] When in use, it is pasted or installed on the surface of the TFT screen. It is very close to the PVC layer of the TFT itself. It has a small absorption effect on the polarized light that has been filtered and transmitted by the polarizer of the TFT screen, and the pass rate is high. ; For non-polarized light such as natural light incident from the outside, the PVC sheet on the diaphragm can achieve about 50% barrier absorption. Therefore, it realizes the weak absorption of the emitted light and the strong absorption of the input light, without significantly increasing the power consumption of the system, while ensuring the lighting effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com