Wide-range optical fiber bending controllable device

A control device, a wide-ranging technology, used in the installation of optical fibers/cables, the use of optical devices to transmit sensing components, measurement devices, etc., can solve the problems of uncontrollable bending angle, limited number of measurement points, errors, etc., to avoid bending loss. , the effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

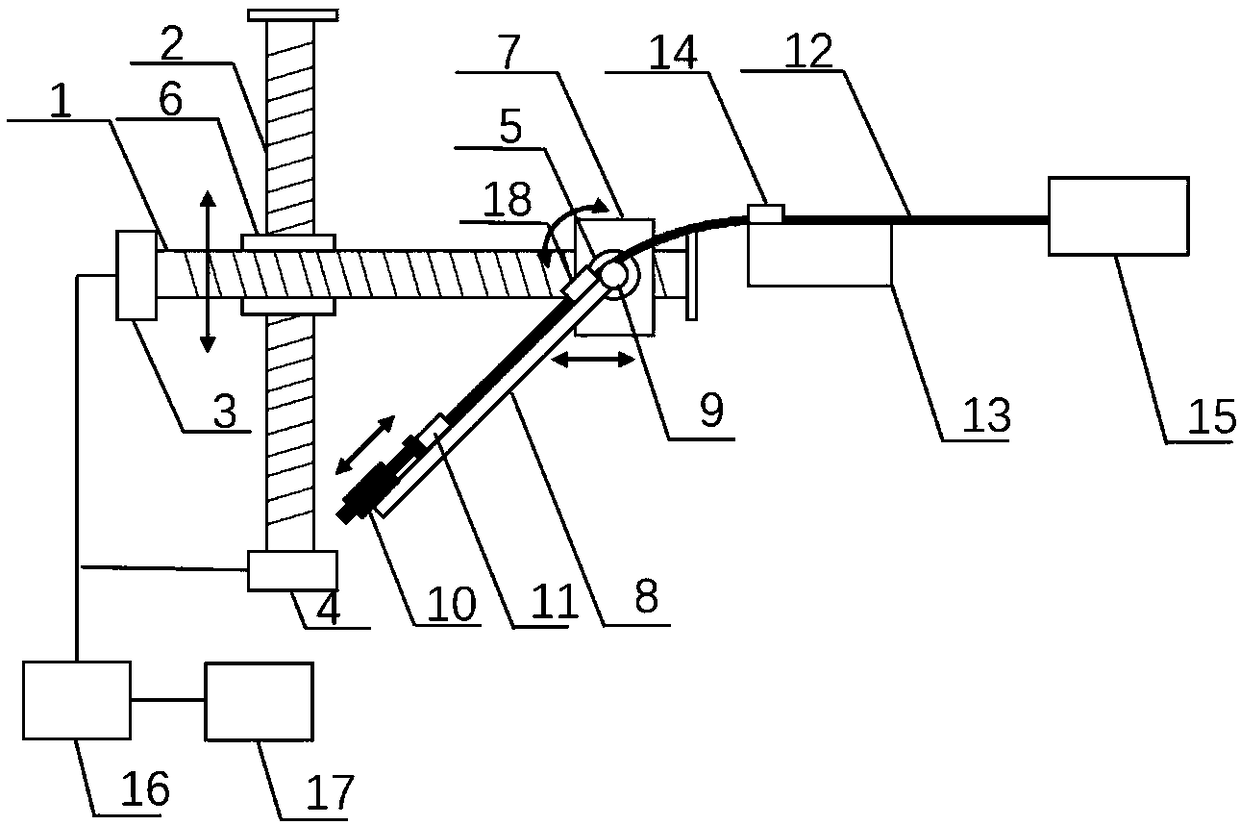

[0032] device such as figure 1 As shown, a large-range optical fiber bending adjustable device includes a rotary displacement unit, a control unit and an optical fiber fixing unit, and is characterized in that the rotary displacement unit includes an X screw slide 1, a Y screw slide 2, Stepping motor X3, stepping motor Y4, stepping motor Z5, moving platform Y6, moving platform X7 and optical fiber rotating fixed plate 8; among them, X screw slide 1 is fixed on Y screw slide 2 through moving platform Y6 , which is controlled by the stepper motor Y4 to move vertically on the Y screw slide 2; the stepper motor Z5 is fixed on the X screw slide 1 through the mobile platform X7, and is controlled by the stepper motor X3 to move on the X screw slide The bar slide table 1 moves in the horizontal direction; the optical fiber rotation fixing plate 8 is arranged on the stepper motor Z5 for controlling the rotation angle of the optical fiber; the optical fiber fixing unit includes an opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com