Friction coupling

A technology of friction clutches and friction surfaces, applied in the direction of friction clutches, clutches, mechanically driven clutches, etc., can solve the problems of high manufacturing costs and installation costs, and achieve the effects of small disengagement stroke loss, small disengagement force, and guaranteed operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

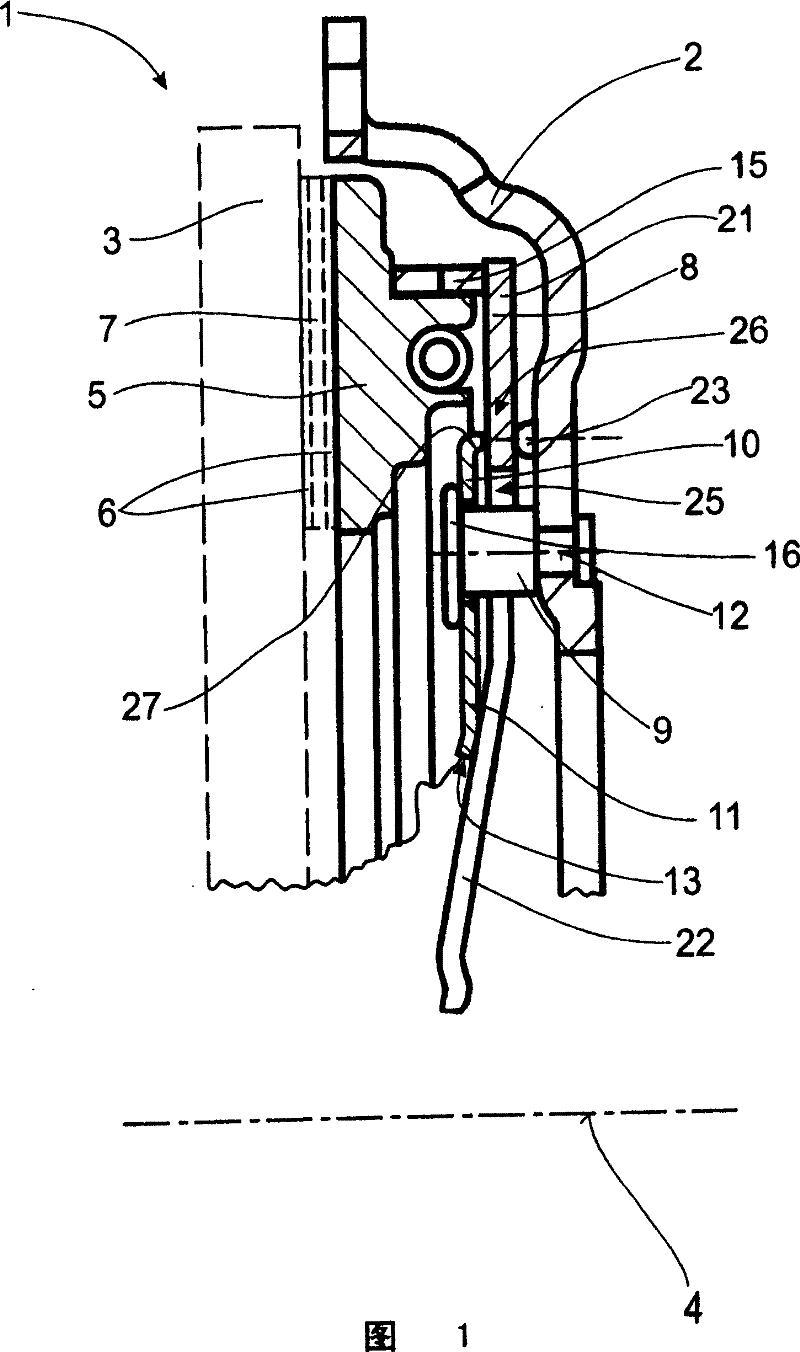

[0060] exist figure 1 A conventionally constructed friction clutch 1 can be seen in the drawing. Housing 2 is connected in a rotationally fixed manner to a flywheel 3 (shown in dashed lines) of the internal combustion engine, housing 2 being rotatable about a common axis of rotation 4 . Alternatively, a dual-mass flywheel can also be provided as flywheel 3 , as is shown, for example, in DE 139 39 030 A1 or in DE 19820 503 A1. A pressure plate 5 is arranged in the housing 2 in a rotationally fixed manner but axially displaceable, which pressure plate 5 has a wear compensation device 15 in the exemplary embodiment shown here. A clutch disc 7 (not shown) with a friction lining 6 is arranged between the pressure plate 5 and the flywheel 3 . In this case, the friction lining 6 has a friction surface 6 which cooperates with a corresponding counter-friction surface on the flywheel 3 and on the pressure plate 5 in the engaged state for the transmission of torque. A diaphragm spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com