Wide load high-pressure steam supply system

A steam supply system and load technology, applied in the direction of steam generation, feed water heater, preheating, etc., to achieve the effect of solving insufficient heating capacity, ensuring economical operation, and broadening the load range of the unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following describes the substantive content of the present invention in detail in conjunction with the drawings and embodiments, but does not limit the protection scope of the present invention.

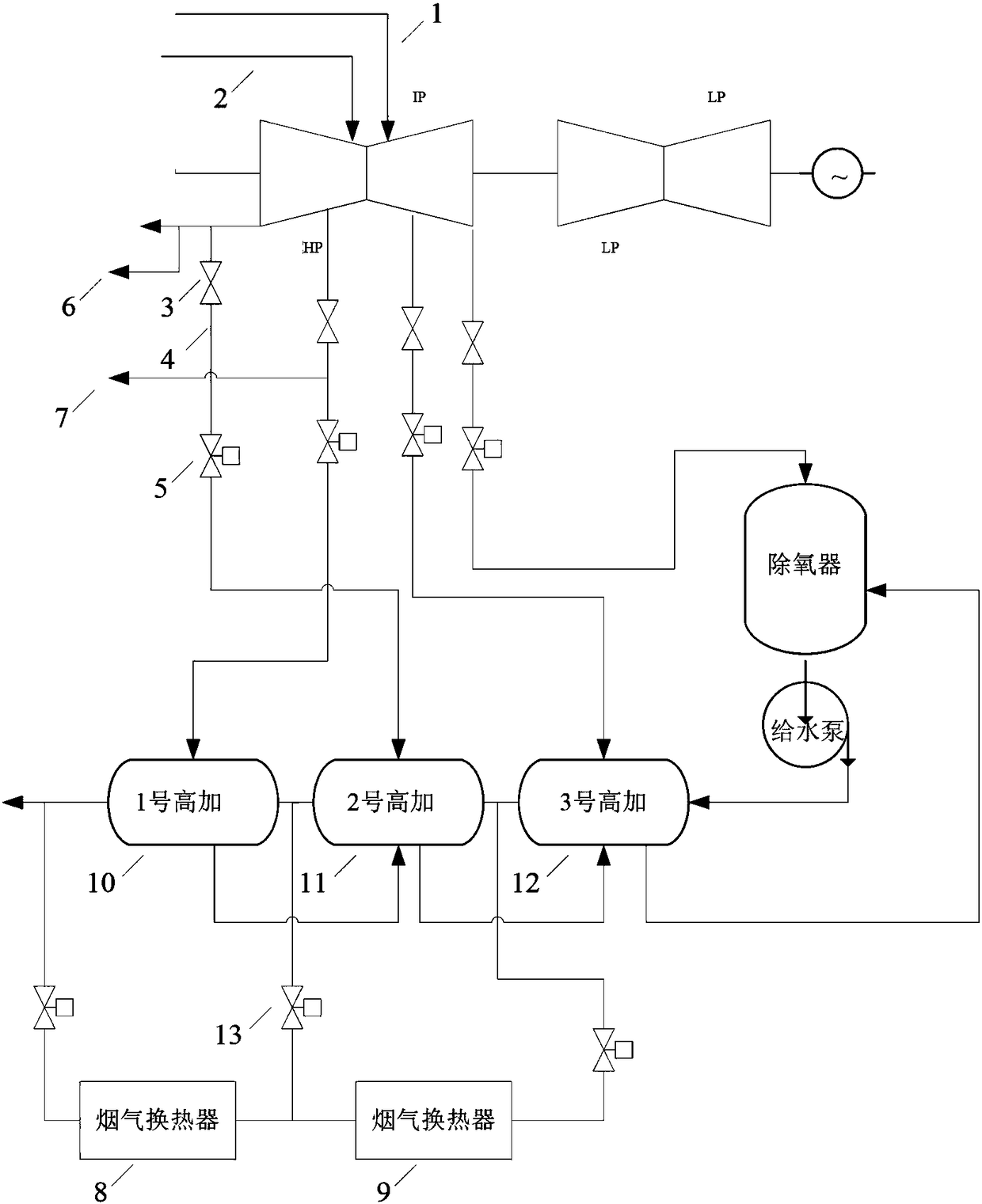

[0015] Such as figure 1 A wide-load high-pressure steam supply system shown includes a steam turbine high-pressure cylinder and No. 1, No. 2, and No. 3 high-pressure heaters. The high-pressure cylinders are respectively connected to No. 1, No. 2, and No. 3 high-pressure heaters through steam extraction pipes. Each extraction pipeline is equipped with a check valve and an electric valve; the extraction pipeline used to connect the high-pressure cylinder of the steam turbine with the No. 1 high-pressure heater is also equipped with an external steam supply pipeline; a No. 1 high-pressure heater feed water Bypass and No. 2 high-pressure heater feedwater bypass, the two feedwater bypasses are respectively equipped with flue gas heat exchangers, and the feedwater bypasses on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com