Ventilation and smoke discharge method for train fire in subway section

A technology for trains in intervals, applied in the field of safety, can solve problems such as suffocation death, passenger poisoning, and rapid spread of fire smoke, etc., to achieve long escape time and improve the effect of subway safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

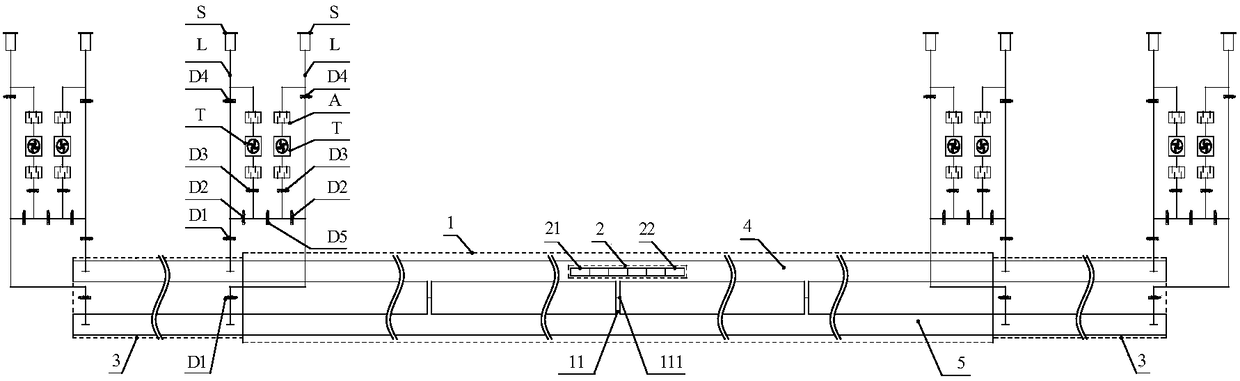

[0028] The subway interval tunnel fire ventilation and smoke exhaust system adopted by the method of the present invention comprises a subway interval tunnel smoke exhaust duct, an interval tunnel blower fan, an air valve and an air pavilion; the subway tunnel includes a first tunnel and a second tunnel, and the interval tunnel in the first tunnel At the junction with the station tunnel, at the junction of the interval tunnel of the second tunnel and the station tunnel, there are tuyeres, and the tuyere is connected with a smoke exhaust duct, and a fan and a damper are arranged in the smoke exhaust duct. The wind pavilions are connected.

[0029] see figure 1 and figure 2 The two parallel first tunnels 4 and the second tunnels 5 of the subway tunnel 1 shown in this embodiment are all connected with a smoke exhaust duct L, the top is connected with a smoke exhaust pavilion S, and a fan is arranged in the smoke exhaust duct. The valve controls smoke exhaust or air supply (the...

Embodiment 2

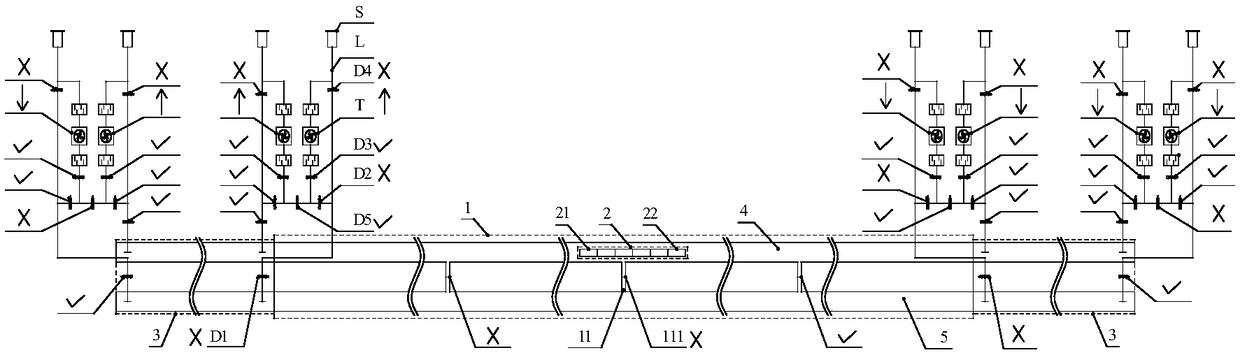

[0034] figure 2 It is a schematic diagram of the first smoke exhaust air supply mode. In the figure, × means off, √ means on, and the up and down arrows indicate the direction of air flow generated by the section tunnel fan after it is turned on.

[0035] The operation of the first smoke exhaust air supply mode is as follows: in the initial state, all section tunnel fans T, air valves (D1, D2-D5 in the figure), fire doors 111, etc. are closed; in the first tunnel 4 When the locomotive 21 of the train (the present embodiment is set as the locomotive 21) is on fire, the passengers evacuate to the end of the train that is not on fire, and open the 2 intervals at the end where the end of the subway train 2 is on fire in the first tunnel 4 is away from the subway train 2 on fire. The tunnel fan T and the damper D1 of the first branch of the corresponding smoke exhaust duct, the damper D2 of the second branch of the smoke exhaust duct, and the damper D3 of the third branch of the ...

Embodiment 3

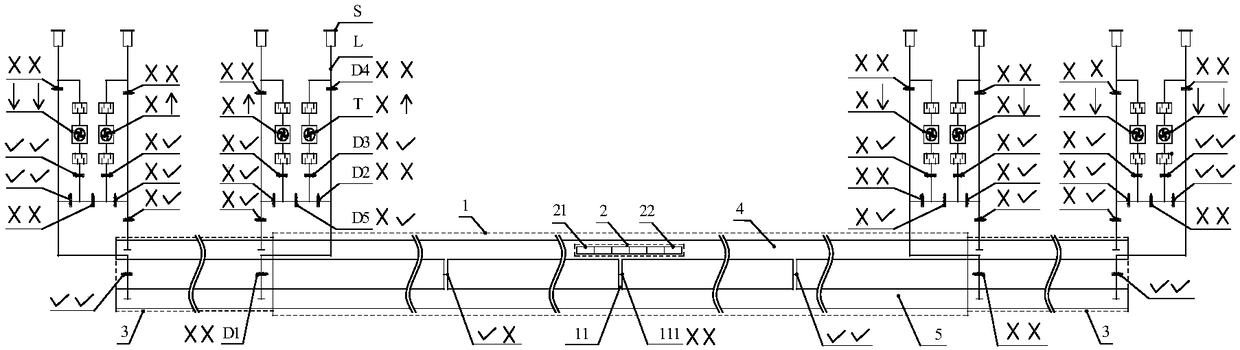

[0037] image 3 It is a schematic diagram of the second smoke exhaust air supply mode. In the figure, × means off, and √ means on. For example, ×× means two-step operation of first closing and then still closing. The time interval between the two steps of each device is the same.

[0038] The up and down arrows indicate the direction of air flow after the section tunnel fan is turned on, and the free combination of ×, √ and up and down arrows indicates that a single function is executed in sequence, and the specific execution time interval is determined according to the requirements of the smoke exhaust mode.

[0039] The operation of the second smoke exhaust air supply mode is as follows: in the initial state, all section tunnel fans T, air valves (D1, D2-D5 in the figure), fire doors 111, etc. are closed; in the first tunnel 4 When the middle part of the subway train 2 is on fire, open the fire doors 111 of the nearest two connecting passages 11 at the two ends of the subwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com