Electrically-heated ceramic tile with fracture preventing function

An electric heating and ceramic tile technology, applied in the field of electric heating ceramic tiles, can solve the problems such as bulging and falling off of the edge of the ceramic tile, and achieve the effect of preventing heat flow, preventing electric leakage and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

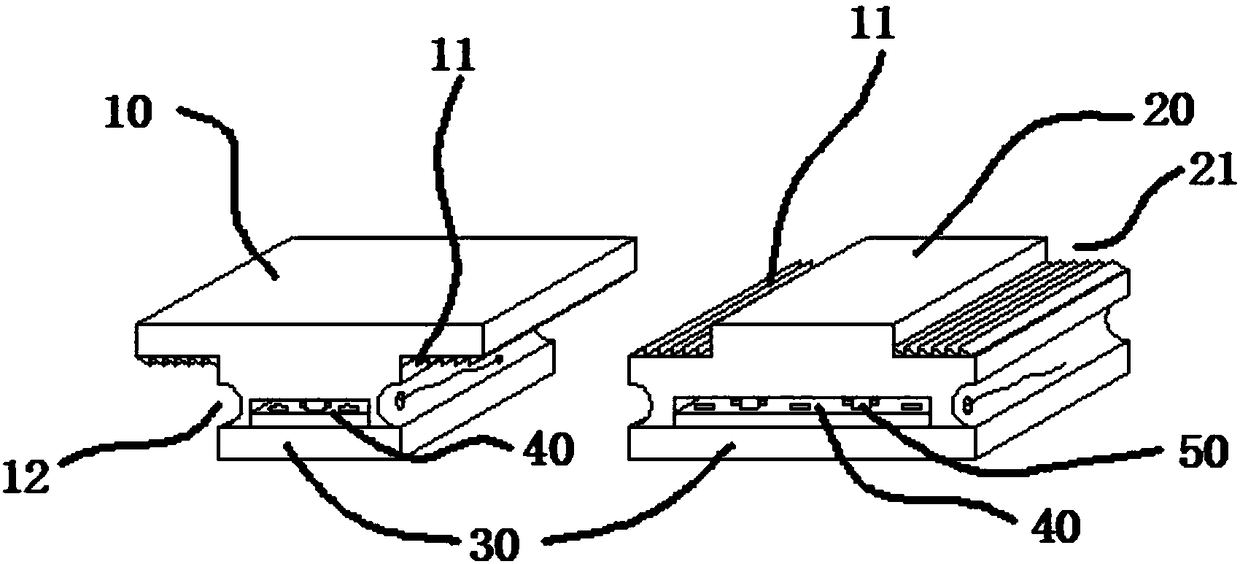

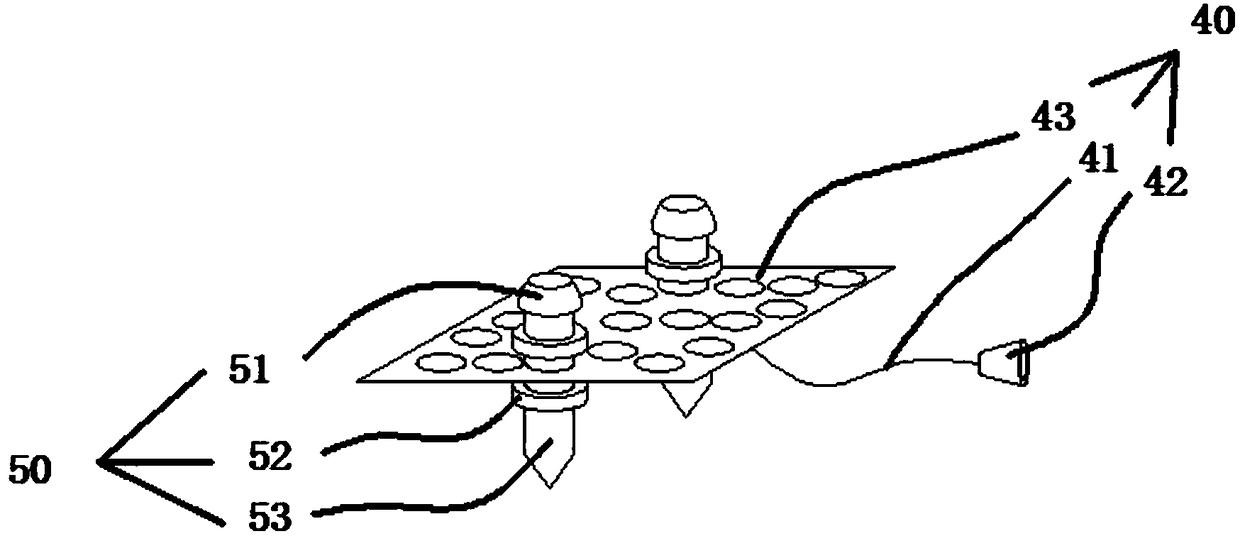

[0029] Such as figure 1 , figure 2 and image 3 As shown, an electric heating ceramic tile with the function of preventing breakage includes: extension plates are provided at both ends of the top of the main tile 10, and at least one block 11 is arranged at intervals along the length direction of the main tile 10 on the bottom end of the extension plate; The auxiliary brick plate 20 can be mosaic connected with the main brick plate 10;

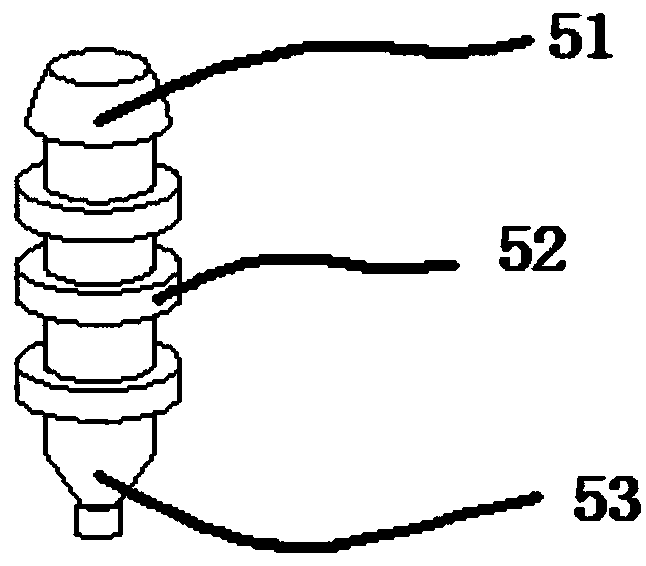

[0030] Both ends of the main brick 10 and the auxiliary brick 20 are provided with grooves 12, and the grooves 12 at the bottom of the main brick 10 and the auxiliary brick 20 are combined into a cable hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com