Pretreatment technology of hydraulic plunger workpiece

A hydraulic column and workpiece technology, which is applied in the field of pretreatment of hydraulic plunger workpieces, can solve the problems of low workpiece pass rate and poor processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

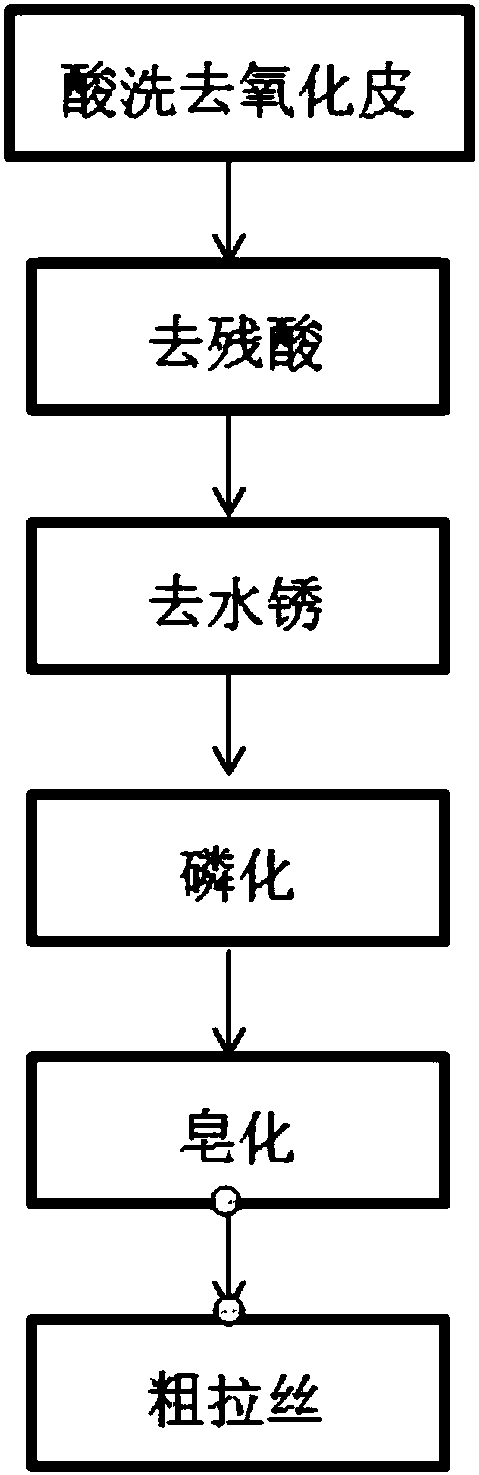

[0030] Such as figure 1 Shown, a kind of pretreatment process of hydraulic plunger workpiece, comprises the following steps:

[0031] 1.1) Pickling and descaling step: Hoist the raw materials, run them through the automatic line into the pickling tank for pickling, and obtain the descaling material, wherein the pickling tank is heated through a natural gas pipeline to ensure a constant temperature; the pickling uses Concentrated hydrochloric acid pickling, the concentration is 18% to 35%, the heating temperature is stable at 55°C to 65°C, and the treatment time is 100 minutes to 180 minutes; the standard after treatment is that the raw material has no scale. The current pickling is not heated, which makes the whole process very limited by the ambient temperature and reduces the pickling effect, especially in winter, the pickling effect is very poor. When using this scheme to set up natural gas pipelines for heating and temperature control, the pickling effect can be improved ...

Embodiment 2

[0038] Such as Figure 1 to Figure 13 As shown, a system for heat treating a hydraulic plunger workpiece includes the following steps:

[0039] 1.1) Pickling and descaling step: Hoist the raw materials, run them through the automatic line into the pickling tank for pickling, and obtain the descaling material, wherein the pickling tank is heated through a natural gas pipeline to ensure a constant temperature; the pickling uses Concentrated hydrochloric acid pickling, the concentration is 18% to 35%, the heating temperature is stable at 55°C to 65°C, and the treatment time is 100 minutes to 180 minutes; the standard after treatment is that the raw material has no scale. The current pickling is not heated, which makes the whole process very limited by the ambient temperature and reduces the pickling effect, especially in winter, the pickling effect is very poor. When using this scheme to set up natural gas pipelines for heating and temperature control, the pickling effect can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com