Deceleration processing equipment based on material stirring

A technology for processing equipment and materials, which is applied in the field of deceleration processing equipment based on material mixing, and can solve problems such as large volume, failure to meet quality requirements, product quality defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

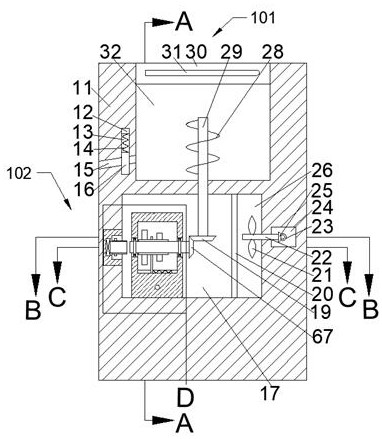

[0020] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0021]The deceleration processing equipment based on material stirring according to the present invention includes a material processing machine 11, a stirring chamber 32 is arranged on the upper side of the material processing machine 11, and a material processing device 101 is arranged in the stirring chamber 32, so that Described material processing device 101 comprises the stirring shaft 29 that rotates and is located in described stirring chamber 32, and described stirring chamber 32 is provided with the stirring blade 28 that is fixed on the outer circle of described stirring shaft 29, and described stirring blade 28 can carry out Material stirring, the rear side of the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com